GB Q345 Steel Angle with High Quality 75*75mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of GB Q345 Steel Angle with High Quality 75*75mm:

1.Standards: GB

2.Material: Q345 or Equivalent

3.Length: 6m, 12m

4.Size:

| Size (mm) | Mass (kg/m) | Size (mm) | Mass (kg/m) |

| 75*75*6 | 6.905 | 75*75*8 | 9.030 |

| 75*75*7 | 7.976 |

Usage & Applications of GB Q345 Steel Angle with High Quality 75*75mm:

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

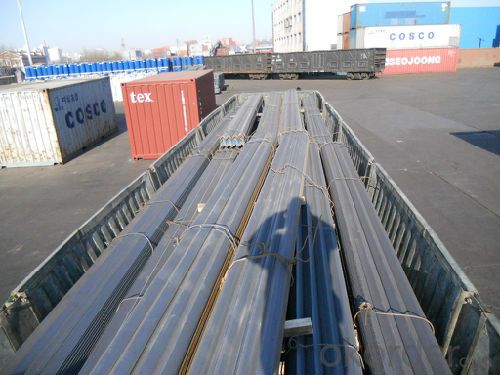

Packaging & Delivery of GB Q345 Steel Angle with High Quality 75*75mm:

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customers' request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 30 to 45 days from the beginning of production.

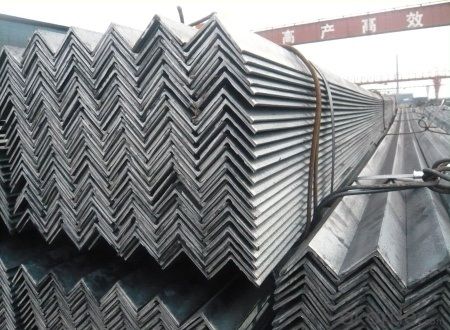

Images of GB Q345 Steel Angle with High Quality 75*75mm:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: Are steel angles suitable for outdoor furniture?

- Steel angles are indeed appropriate for outdoor furniture. Steel is known for its durability and strength, enabling it to endure diverse weather conditions. This quality makes it an exceptional selection for outdoor furniture. Steel angles contribute to stability and structural support, guaranteeing that the furniture can bear heavy loads and remain firm. Furthermore, when properly treated, steel is resistant to rust and corrosion, which is crucial for outdoor furniture exposed to moisture and changing weather. In addition, steel angles offer a sleek and contemporary aesthetic, enabling versatile design possibilities for outdoor furniture. In summary, the durability, strength, and resistance to environmental elements make steel angles a dependable and long-lasting option for outdoor furniture.

- Q: How are steel angles defined?

- Steel angles are characterized by their shape and dimensions. They consist of L-shaped steel components with two perpendicular legs of either equal or unequal lengths. The angle formed between these legs can vary from 90 to 180 degrees, depending on the specific design and purpose. In construction and engineering projects, steel angles are widely utilized to provide structural support, reinforcement, and stability. To determine their strength, load-bearing capacity, and versatility, the dimensions of steel angles are typically specified in terms of leg length, thickness, and overall length. Due to their diverse applications across various industries, steel angles are available in different finishes, such as galvanized or painted, to enhance their durability and resistance against corrosion.

- Q: Can steel angles be used for pedestrian bridges or walkways?

- Indeed, pedestrian bridges or walkways can utilize steel angles. Construction frequently employs steel angles owing to their robustness, longevity, and adaptability. By means of simple fabrication and welding, steel angles can effortlessly form the desired structural components for bridges and walkways. Bearing exceptional load capacities, steel angles are well-suited for supporting pedestrian traffic. Moreover, steel's corrosion-resistant qualities render it an ideal option for outdoor applications subject to weather exposure. In summary, the reliability and capacity to meet essential structural criteria render steel angles a favored selection for pedestrian bridges and walkways.

- Q: Can steel angles be painted or finished for decorative purposes?

- Yes, steel angles can be painted or finished for decorative purposes. Steel angles, which are commonly used in construction and industrial applications, can be painted or finished to enhance their appearance and provide a decorative touch. Painting steel angles can help protect them from corrosion and rust while also allowing for customization to match the aesthetic requirements of the project. Additionally, finishes such as powder coating, electroplating, or galvanizing can be applied to steel angles to further enhance their appearance and durability. By painting or finishing steel angles, they can be seamlessly integrated into various architectural and design projects, making them both functional and visually appealing.

- Q: What is the typical width of a steel angle?

- The typical width of a steel angle can vary depending on its intended use and the specific requirements of the project. However, in general, steel angles are available in a wide range of sizes and dimensions. Commonly, the width of a steel angle can range from 1 inch to 8 inches or more. It is important to consult the relevant industry standards and specifications to determine the appropriate width for a specific application.

- Q: How are steel angles measured?

- Two main dimensions are used to measure steel angles: the length of each leg and the thickness of the material. Each leg's length refers to the distance from the intersection point of the two legs to the end of each leg. This measurement is typically expressed in inches or millimeters. The material's thickness, also known as the gauge, measures the width of the steel angle. It is commonly expressed in fractions of an inch or millimeters. To provide a comprehensive measurement, steel angles are often described by combining these two dimensions. For instance, a typical specification could be "2 x 2 x 1/4," indicating that the steel angle has legs measuring 2 inches in length, a thickness of 1/4 inch, and both legs are of equal length. It's worth noting that steel angles can be measured differently depending on the specific industry or region. Metric measurements may be used in some industries, while others may prefer imperial measurements. Therefore, it's always advisable to verify the measuring standards used in a particular context to ensure accurate understanding and communication.

- Q: What are steel angles used for?

- Steel angles are commonly used in construction and manufacturing industries for a variety of purposes. One of the main uses of steel angles is in structural applications. They are often used as supports, braces, and reinforcements in buildings, bridges, and other infrastructure projects. The L-shape of the angle provides added strength and stability, making it an ideal choice for constructing load-bearing structures. Steel angles are also used in the manufacturing industry for fabricating various products. They can be welded, drilled, and cut to create custom shapes and structures. They are commonly used as frames, brackets, and supports for machinery, equipment, and vehicles. Additionally, steel angles are used in the fabrication of furniture, shelves, racks, and other storage solutions. Their sturdy construction makes them suitable for supporting heavy loads, making them ideal for applications in warehouses, garages, and factories. In summary, steel angles are versatile and widely used in construction and manufacturing industries for their strength, stability, and adaptability. From supporting structures to fabricating products, they play a crucial role in various applications.

- Q: How are steel angles protected against atmospheric corrosion?

- There are various methods available to protect steel angles from atmospheric corrosion. One commonly used method is the application of a protective coating, such as paint, on the surface of the steel angles. This coating acts as a barrier, preventing direct contact between the steel and moisture or oxygen, which are the main causes of corrosion. Another method of protection is galvanization. Galvanization involves coating the steel angles with a layer of zinc, either through hot-dip galvanization or electroplating. The zinc acts as a sacrificial layer, corroding instead of the steel. This sacrificial corrosion process helps safeguard the steel angles from atmospheric corrosion. Apart from coatings, inhibitors can also be used to protect steel angles. Inhibitors are substances that can be added to the environment or applied directly to the steel surface to slow down or prevent corrosion. These inhibitors work by forming a protective film on the steel surface or by altering the chemical environment to reduce corrosion. Regular maintenance and inspection are crucial in protecting steel angles against atmospheric corrosion. This includes cleaning the surface of the steel angles to remove any dirt or debris that can trap moisture and speed up corrosion. It is also important to promptly repair any damaged or deteriorated coatings to ensure continuous protection against corrosion. In conclusion, a combination of protective coatings, galvanization, inhibitors, and regular maintenance is necessary to effectively shield steel angles from atmospheric corrosion and prolong their lifespan.

- Q: Can steel angles be used in agricultural or farm applications?

- Yes, steel angles can be used in agricultural or farm applications. Steel angles are versatile and durable structural components that are commonly used in various industries, including agriculture. They can be utilized in farm equipment, such as machinery frames, trailers, and fences. Steel angles are ideal for these applications due to their strength and stability, which can withstand heavy loads and harsh weather conditions. Additionally, they can be easily welded, bolted, or fastened together, allowing for easy customization and construction of various agricultural structures. Overall, steel angles are a reliable and practical choice for agricultural and farm applications.

- Q: Can steel angles be used for fencing and gate construction?

- Yes, steel angles can be used for fencing and gate construction. Steel angles provide structural support and stability, making them suitable for building sturdy fences and gates. They can be used to create frames, braces, and posts, ensuring durability and security.

Send your message to us

GB Q345 Steel Angle with High Quality 75*75mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords