Hot Rolled Mild Steel Plate JIS SS400 Carbon Steel Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel sheet, steel plate, mild steel sheet, carbon steel sheet

Size | Thickness:2.0-200mm |

Application | Steel plates are widly used as boiler plate, container plate, flange plate and ship plate, and also widly used in building construction. The size of steel plate can be made according to clients requirements. |

Packing | In bulk or as required |

| Delivery time | Within 10-25 days after order confirmed and L/C received |

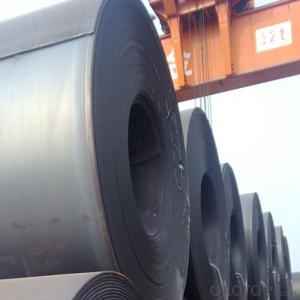

Workshop Show

Shipping

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

Package Informations

1) EXPORT, In 20 feet (GW 25 ton) or 40 feet Container (GW 25 ton)

2)as customer's requirement

Why choose us?

(1) The leading exporter in China special steel industry.

(2) Large stocks for various sizes, fast delivery date.

(3) Good business relationship with China famous factories.

(4) More than 7 years steel exporting experience.

(5) Good after-sales service guarantee.

- Q: How does special steel perform in high-pressure environments?

- Special steel performs exceptionally well in high-pressure environments due to its high tensile strength, excellent corrosion resistance, and ability to withstand extreme temperatures. Its superior mechanical properties make it highly suitable for applications such as oil and gas pipelines, pressure vessels, and offshore drilling equipment, where it can effectively handle the intense pressures and maintain structural integrity even under harsh conditions.

- Q: What are the different low-temperature grades of special steel?

- There are several different low-temperature grades of special steel that are designed to withstand extreme cold conditions. Some of the commonly used grades include: 1. Austenitic Stainless Steel: This grade of steel, such as 304 and 316, is known for its excellent corrosion resistance and high strength at low temperatures. It is commonly used in cryogenic applications, such as LNG storage tanks and cryogenic piping. 2. Ferritic Stainless Steel: Ferritic stainless steel grades like 410 and 430 are suitable for low-temperature applications due to their good ductility and resistance to stress corrosion cracking. They are often used in cryogenic environments where high strength and resistance to embrittlement are required. 3. Martensitic Stainless Steel: Martensitic stainless steel, such as 410 and 420, exhibits high strength and good toughness even at low temperatures. It is commonly used in applications that require high wear resistance and strength, such as valves and turbine blades in cryogenic systems. 4. Duplex Stainless Steel: Duplex stainless steel grades like 2205 and 2507 offer a combination of high strength, excellent corrosion resistance, and good toughness at low temperatures. They are widely used in offshore and subsea applications where low-temperature performance and resistance to pitting and crevice corrosion are critical. 5. Nickel-Based Alloys: Nickel-based alloys, such as Inconel and Hastelloy, are known for their exceptional corrosion resistance and high strength at both low and high temperatures. These alloys are extensively used in cryogenic applications, including liquefied natural gas (LNG) processing plants, as well as aerospace and chemical processing industries. Each of these low-temperature grades of special steel offers unique properties and advantages, making them suitable for various applications in extreme cold conditions. The selection of the appropriate grade depends on factors like the specific temperature range, required corrosion resistance, strength requirements, and environmental conditions.

- Q: How does special steel contribute to the marine aftermarket industry?

- Special steel plays a crucial role in the marine aftermarket industry by offering a wide range of benefits and applications. Firstly, special steel is known for its exceptional strength and durability, making it an ideal material for manufacturing marine components and parts. These components include propeller shafts, rudders, marine engine parts, and various structural elements. The marine environment is harsh and corrosive, with constant exposure to saltwater, waves, and extreme weather conditions. Special steel, such as stainless steel or corrosion-resistant alloys, is specifically designed to withstand these corrosive elements. It provides excellent resistance to rust, pitting, and other forms of corrosion, ensuring the longevity and reliability of marine equipment. Furthermore, special steel is often used in high-performance marine engines and turbines due to its excellent heat resistance and mechanical properties. It can withstand high temperatures and pressures, making it suitable for marine propulsion systems that require superior performance and efficiency. Additionally, special steel is employed in the construction of marine vessels, including ships, offshore platforms, and submarines. Its high strength-to-weight ratio allows for the construction of lightweight yet sturdy structures, leading to improved fuel efficiency and overall performance. Moreover, special steel's ability to withstand impact and fatigue loading makes it an essential material for ensuring the safety and structural integrity of marine vessels. Moreover, special steel contributes to the marine aftermarket industry through its versatility. It can be easily fabricated and customized to meet specific design requirements, allowing for the production of unique and tailored marine components. This flexibility enables the marine aftermarket industry to provide a wide range of replacement parts and upgrades for existing vessels, enhancing their performance, efficiency, and safety. In summary, special steel is a vital component in the marine aftermarket industry. Its strength, durability, corrosion resistance, and versatility make it an essential material for manufacturing marine components, constructing vessels, and improving overall performance. With its unique properties, special steel helps ensure the safety, reliability, and efficiency of marine equipment, contributing to the growth and success of the marine aftermarket industry.

- Q: What are the different heat treatment furnaces used for special steel?

- Special steel is commonly subjected to various heat treatment processes using different types of furnaces. Each furnace serves a specific purpose and is engineered to create the ideal heating and cooling conditions necessary for the steel to attain its desired properties. One of the furnaces employed for special steel is the annealing furnace. This furnace utilizes a technique called annealing, which entails heating the steel to a specific temperature and then gradually cooling it to enhance its softness and ductility. To prevent oxidation during the process, annealing furnaces are often equipped with controlled atmospheres. Another type of furnace utilized for special steel is the quenching furnace. Quenching is a process that involves rapidly cooling the steel to increase its hardness. Quenching furnaces are designed to provide the required cooling rate and may utilize specialized cooling mediums like oil or water to achieve the desired outcome. Tempering furnaces are also commonly employed for special steel. Tempering involves heating the steel to a specific temperature and subsequently cooling it to enhance its toughness and reduce brittleness. These furnaces enable precise temperature control throughout the tempering process. Furthermore, carburizing furnaces are utilized for special steel. Carburizing is the process of introducing carbon into the surface of the steel to enhance its hardness. Carburizing furnaces are equipped with controlled atmospheres and designed to provide the necessary temperatures and carbon-rich environments for the carburizing process. In summary, the various heat treatment furnaces used for special steel serve distinct purposes such as annealing, quenching, tempering, or carburizing. These furnaces are meticulously engineered to provide the requisite heating and cooling conditions for the steel to achieve its desired properties.

- Q: Can special steel be used in high-speed applications?

- Yes, special steel can definitely be used in high-speed applications. Special steel refers to a range of steel alloys that have been specifically developed and engineered to possess enhanced properties such as high strength, durability, and resistance to wear and corrosion. These properties make special steel suitable for various demanding applications, including high-speed ones. In high-speed applications, such as aerospace, automotive, machining, and power generation, the material needs to withstand extreme conditions, including high temperatures, vibrations, and mechanical stress. Special steel is designed to meet these requirements and provide excellent performance even under such challenging conditions. For example, high-speed steel (HSS) is a type of special steel that is specifically formulated to retain its hardness and strength at elevated temperatures, making it ideal for cutting tools like drills, end mills, and saw blades. Similarly, stainless steel variants like martensitic and precipitation-hardening stainless steels are commonly used in high-speed applications due to their high strength, toughness, and resistance to corrosion. Moreover, the development of advanced manufacturing techniques, such as powder metallurgy, has allowed the production of special steel with even better properties, including higher hardness, improved wear resistance, and superior dimensional stability. These advancements have further expanded the application range of special steel in high-speed industries. In summary, special steel is a versatile and reliable material that can be successfully employed in high-speed applications. Its unique properties make it suitable for withstanding the demanding conditions and providing excellent performance, making it a preferred choice for industries requiring materials that can withstand high speeds, temperatures, and mechanical stress.

- Q: What are the applications of special steel in the power generation manufacturing process?

- Special steel is widely used in the power generation manufacturing process due to its exceptional properties. It is utilized in various applications such as turbine blades, boiler tubes, and heat exchangers. The high strength and temperature resistance of special steel enable it to withstand the harsh conditions in power plants, ensuring reliable operation and increased efficiency. Additionally, its corrosion resistance properties help maintain the integrity of components, extending their lifespan and reducing maintenance costs. Overall, the applications of special steel in power generation manufacturing play a crucial role in enhancing the performance and durability of power plant equipment.

- Q: What are the main advantages of using special steel in the defense industry?

- The main advantages of using special steel in the defense industry are its exceptional strength, durability, and resistance to wear and tear. Special steel alloys can withstand extreme conditions, such as high temperatures and pressures, making them ideal for military applications. Additionally, special steel offers enhanced corrosion resistance, ensuring the longevity of defense equipment even in harsh environments. Its high impact resistance and ability to absorb shock also make it valuable in protecting soldiers and military vehicles. Overall, special steel provides crucial advantages in terms of reliability, performance, and protection for the defense industry.

- Q: How does the addition of nickel enhance the properties of special steel?

- The properties of special steel are enhanced in several ways through the addition of nickel. To begin with, the strength of steel is increased by nickel, resulting in enhanced durability and resistance to deformation. This is particularly crucial in situations where the steel will be exposed to high temperatures or heavy loads. Additionally, the corrosion resistance of steel is improved by nickel. When exposed to moisture or harsh chemicals, nickel forms a protective oxide layer on the steel's surface, preventing rusting or corrosion. This is particularly valuable in industries like marine, aerospace, and chemical processing, where steel is frequently subjected to corrosive environments. Furthermore, the toughness of steel is improved by nickel, allowing it to withstand impact or sudden temperature changes without fracturing or cracking. This makes it suitable for applications that require high resistance to shock or vibration, such as construction, automotive, or machinery manufacturing. Moreover, nickel enhances the heat resistance of steel. By increasing the steel's ability to retain strength and shape at high temperatures, nickel makes it suitable for use in high-temperature environments, such as power generation, oil and gas, or furnace systems. In conclusion, the addition of nickel to special steel enhances its strength, corrosion resistance, toughness, and heat resistance. These improved properties make nickel-enhanced steel highly desirable in a wide range of industries and applications, where durability, reliability, and performance under challenging conditions are of utmost importance.

- Q: What are the different tooling grades of special steel?

- There are various tooling grades of special steel, each designed to fulfill specific requirements and applications. Some common tooling grades include high-speed steel (HSS), which is known for its excellent heat resistance and durability; carbide steel, which is extremely hard and suitable for cutting tools; and stainless steel, which offers corrosion resistance and is commonly used for precision tools. Other tooling grades may include alloy steel, tool steel, and die steel, among others, each tailored to different tooling needs.

- Q: What are the applications of special steel in the manufacturing industry?

- Special steel has various applications in the manufacturing industry due to its exceptional properties. It is commonly used in the production of machinery, tools, and equipment, including automotive parts, aerospace components, and turbines. Special steel's high strength, durability, and resistance to corrosion make it ideal for demanding applications such as oil and gas exploration, construction, and defense. Additionally, its heat resistance and electrical conductivity make it suitable for manufacturing appliances, electrical transformers, and power generation equipment. Overall, special steel plays a crucial role in enhancing the performance, reliability, and safety of numerous industrial products.

Send your message to us

Hot Rolled Mild Steel Plate JIS SS400 Carbon Steel Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords