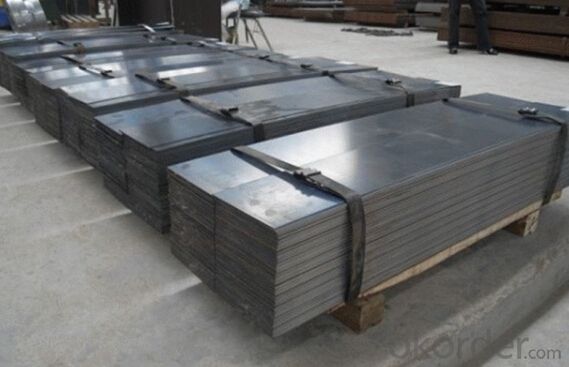

Hot Rolled Carbon Steel Plate Sheet Grade A36 SS400 ST37 Q235 S235JR

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

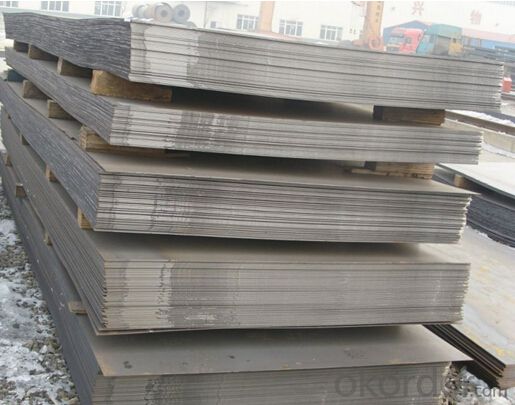

Prime Hot Rolled Carbon Steel Plate_Sheet Grade A36_SS400_ST37_Q235_S235JR

Thickness:2mm-100mm

Width:1000-4000mm

MOQ: 3m.t.

Certificate: ISO, SGS

Specification of Hot Rolled Carbon Steel Plate_Sheet Grade A36_SS400_ST37_Q235_S235JR

Commodity | Prime hot rolled carbon steel plate / sheet dimensions |

Thickness | 0.6-200mm |

Width | 1000-4000mm |

Length | as custom's request |

Technique | Cold rolled or hot rolled mild steel plate |

Surface treatment | Bare, galvanized coated or as customer's requirements. |

Standard | ASTM,EN,GB,JIS |

Material | T709-2006, ASTM A36, JIS G3101, DIN EN 10025, SAE 1045, ASTM A570 |

Usage | Mechanical&manufacture,Steel strcuture,Shipbuilding,Bridging,Automobile chassis |

Terms of Payment | 30% T/T as deposit and 70% T/T balance againest B/L copy. |

Delivery Detail | Within 3-15 days after receipt of deposited for the mild steel plate |

CNBM Introduction of the Hot Rolled Carbon Steel Plate_Sheet Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery of the Hot Rolled Carbon Steel Plate_Sheet

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the different types of alloy steel?

- There are several different types of alloy steel, including stainless steel, tool steel, high-strength low-alloy steel, and maraging steel. Each type has its own unique composition and properties, making them suitable for various applications in industries such as construction, automotive, and aerospace.

- Q: How does special steel contribute to the automotive racing aftermarket industry?

- Special steel plays a crucial role in the automotive racing aftermarket industry by providing the necessary strength, durability, and performance required for high-performance racing vehicles. In this industry, where speed, precision, and safety are paramount, special steel offers unique properties that enable engineers and manufacturers to push the limits of performance. One key way that special steel contributes to the automotive racing aftermarket industry is through its ability to withstand extreme conditions. Racing vehicles are subjected to intense heat, pressure, and vibrations during high-speed races, which can put immense stress on various components. Special steel, with its exceptional heat resistance and high tensile strength, ensures that critical parts like engine components, transmission gears, and suspension systems can withstand these harsh conditions without compromising performance or safety. Furthermore, special steel is known for its lightweight properties, making it an ideal material for racing vehicle components. Weight reduction is a crucial aspect of racing as it directly impacts acceleration, handling, and overall performance. By using special steel, manufacturers can create lighter yet stronger components, allowing racing teams to achieve higher speeds, better maneuverability, and improved fuel efficiency. Special steel also contributes to the automotive racing aftermarket industry by offering excellent machinability and weldability. This allows for precise customization and modification of components, catering to the specific needs and preferences of racing teams. Whether it is creating custom engine blocks, exhaust systems, or chassis reinforcements, special steel provides the flexibility required to optimize performance and gain a competitive edge. Moreover, the use of special steel in the automotive racing aftermarket industry promotes innovation and technological advancements. Steel manufacturers continually develop new alloys and compositions that enhance the performance capabilities of racing vehicles. These advancements can include improved corrosion resistance, better fatigue strength, and enhanced material properties, all of which contribute to the overall performance and longevity of racing vehicle components. In summary, special steel is a vital contributor to the automotive racing aftermarket industry. Its unique combination of strength, durability, lightweight properties, and machinability enables racing teams to design and manufacture high-performance vehicles that can withstand extreme conditions. By leveraging the advantages of special steel, the industry can continue to push the boundaries of automotive racing, delivering faster, safer, and more efficient racing machines.

- Q: Can special steel be used in the pharmaceutical manufacturing equipment manufacturing industry?

- Yes, special steel can be used in the pharmaceutical manufacturing equipment manufacturing industry. Special steel alloys such as stainless steel are commonly used due to their corrosion resistance, durability, and ability to withstand high temperatures and harsh chemicals. These qualities make special steel a suitable choice for various equipment used in pharmaceutical manufacturing, including tanks, reactors, mixers, and piping systems.

- Q: What are the different coating techniques used for special steel?

- There are several different coating techniques used for special steel, including hot-dip galvanizing, electroplating, powder coating, and thermal spraying. Each technique has its own advantages and applications, providing enhanced protection against corrosion, improved aesthetics, or increased durability depending on the specific requirements of the steel.

- Q: How does special steel contribute to the automotive engine industry?

- Special steel plays a crucial role in the automotive engine industry by offering enhanced performance, durability, and efficiency. It is used to manufacture various engine components such as crankshafts, camshafts, connecting rods, and valves, which are subjected to high stress and temperature. The use of special steel ensures these components can withstand the demanding conditions and provide better power, fuel efficiency, and overall engine performance. Additionally, special steel enables engine manufacturers to reduce weight while maintaining structural integrity, contributing to improved fuel economy and reduced emissions.

- Q: How is special steel used in the defense industry?

- Special steel is used in the defense industry for various applications such as manufacturing armored vehicles, aircraft carriers, submarines, and military-grade firearms. Its exceptional strength, durability, and resistance to high temperatures make it ideal for constructing critical components and structures that require enhanced protection and performance in combat situations.

- Q: How does special steel contribute to the infrastructure sector?

- Special steel plays a crucial role in the infrastructure sector by providing enhanced strength, durability, and resistance to various environmental factors. It is used in the construction of bridges, buildings, and other critical infrastructure projects, ensuring structural integrity and safety. Additionally, special steel is utilized in the manufacturing of machinery and equipment used in the sector, further contributing to its efficiency and reliability.

- Q: How does special steel contribute to reducing product costs?

- Special steel contributes to reducing product costs in several ways. Firstly, special steel is known for its high strength and durability, which allows manufacturers to design and produce products that have a longer lifespan. This reduces the need for frequent replacements or repairs, thus saving costs in the long run. Additionally, special steel can be customized to meet specific requirements, allowing for the production of lighter and more efficient products. This can lead to savings in terms of raw material usage, transportation costs, and energy consumption. Moreover, special steel often has excellent corrosion resistance, reducing the need for additional protective coatings or maintenance, which can also result in cost savings. Overall, the utilization of special steel in manufacturing processes helps optimize product performance, longevity, and efficiency, thereby contributing to reducing product costs.

- Q: Can special steel be used in the paper manufacturing industry?

- Yes, special steel can be used in the paper manufacturing industry. Special steels, such as stainless steel, can be used to make various components and equipment used in the paper manufacturing process. These steels offer excellent corrosion resistance, high strength, and durability, making them suitable for applications like paper machine parts, rollers, blades, and screens. Additionally, special steels can withstand high temperatures and mechanical stress, enhancing the overall efficiency and reliability of paper manufacturing operations.

- Q: How does special steel contribute to the aerospace noise reduction?

- Special steel contributes to aerospace noise reduction by providing high strength and durability, which allows for the construction of lighter and more aerodynamic aircraft components. This reduces the overall weight of the aircraft, leading to decreased fuel consumption and noise emissions. Additionally, special steel's unique properties, such as its ability to dampen vibrations and resist corrosion, help to minimize the transmission of noise and vibrations throughout the aircraft structure, resulting in a quieter and more comfortable flying experience for passengers and crew.

Send your message to us

Hot Rolled Carbon Steel Plate Sheet Grade A36 SS400 ST37 Q235 S235JR

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords