High Carbon High Chromium Steel D2 Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Type:

Carbon Steel

Shape:

Steel Round Bar

High Carbon High Chromium Steel D2 Material

Product information:

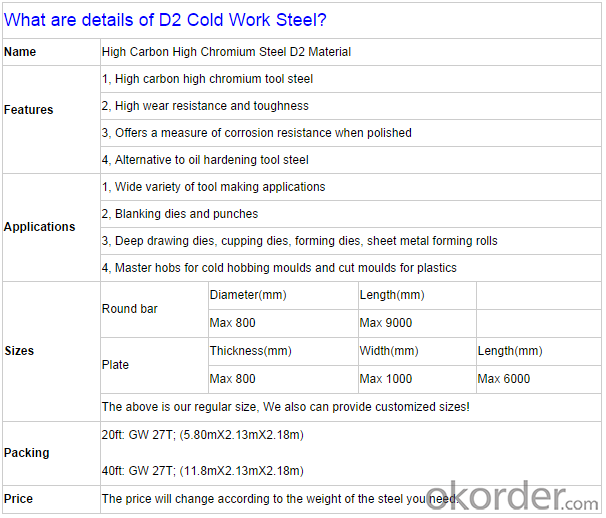

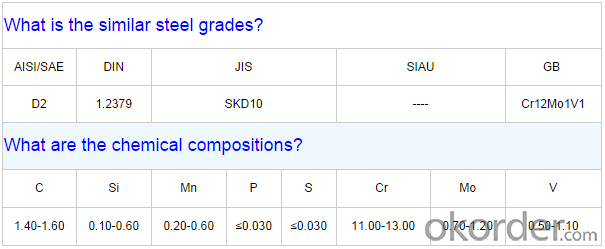

Specifications

High Carbon High Chromium Steel D2 Material

1.Various Specification

2.On Time Delivery

3.Sample: Free

4.24hrs online

Product show

Workshop show

Our service:

- Q: How does stainless steel contribute to the construction industry?

- Stainless steel contributes to the construction industry by providing durability, corrosion resistance, and aesthetic appeal. It is widely used in structural applications, such as building facades, bridges, and roofing, as it can withstand harsh weather conditions and maintain its strength over time. Stainless steel's resistance to corrosion also makes it a suitable choice for plumbing, electrical, and HVAC systems, ensuring longevity and minimizing maintenance. Additionally, its sleek and modern appearance enhances the overall aesthetics of architectural designs.

- Q: What are the key properties of special steel?

- The key properties of special steel include high strength, excellent toughness, good corrosion resistance, and high temperature resistance. Special steel is also known for its ability to be easily machinable and weldable, making it a versatile material for various industries such as automotive, aerospace, and construction.

- Q: What are the main applications of special steel in the power distribution industry?

- Special steel is widely used in the power distribution industry for various applications. One of the main applications is in the construction of transmission towers and electrical pylons. Special steel is preferred for these structures due to its high strength, durability, and resistance to corrosion. It ensures the safe and reliable transmission of electricity over long distances. Special steel is also used in the manufacturing of electrical transformers and generators. The steel's magnetic properties make it suitable for creating efficient and reliable power generation and distribution equipment. Additionally, special steel is used in the production of electrical connectors and conductors, which are essential for ensuring the efficient flow of electricity through power distribution systems. Overall, the main applications of special steel in the power distribution industry include transmission towers, electrical pylons, transformers, generators, and electrical connectors. These applications play a crucial role in maintaining a robust and reliable power grid, ensuring uninterrupted electricity supply to consumers.

- Q: How does special steel perform in terms of chemical resistance?

- Special steel has excellent chemical resistance properties, making it highly resistant to corrosion and oxidation. It is capable of withstanding exposure to various chemicals, acids, and corrosive environments without undergoing significant degradation. This makes special steel a reliable choice for applications that require strong resistance against chemical attack.

- Q: How does special steel contribute to the automotive aftermarket industry?

- Special steel plays a crucial role in the automotive aftermarket industry as it offers enhanced strength, durability, and corrosion resistance compared to regular steel. This allows manufacturers to produce high-performance components such as engine parts, chassis components, and suspension systems. Additionally, special steel's unique properties enable the creation of lighter and more fuel-efficient vehicles. Its contribution to the aftermarket industry lies in providing the necessary materials for the production of high-quality and long-lasting aftermarket parts that meet the demands of vehicle customization and performance upgrades.

- Q: How is special steel used in the defense industry?

- Special steel is used in the defense industry for various applications such as manufacturing armored vehicles, aircraft carriers, submarines, and military-grade firearms. Its exceptional strength, durability, and resistance to high temperatures make it ideal for constructing critical components and structures that require enhanced protection and performance in combat situations.

- Q: What are the main advantages of using special steel in the food processing industry?

- The main advantages of using special steel in the food processing industry are its high resistance to corrosion, durability, and hygiene. Special steel is specifically designed to withstand harsh environments, such as exposure to acidic or alkaline substances, which are common in food processing. It does not rust or react with food, ensuring the quality and safety of the final product. Additionally, special steel is easy to clean and maintain, making it an ideal choice for food processing equipment.

- Q: How is tool steel used in the manufacturing of molds and dies?

- Tool steel is used in the manufacturing of molds and dies due to its exceptional hardness, wear resistance, and toughness. It allows for the creation of precise and durable molds and dies that can withstand the high pressures and temperatures involved in various manufacturing processes. Tool steel also provides excellent dimensional stability, ensuring the accuracy and consistency of the final products.

- Q: How does special steel contribute to the construction industry?

- Special steel contributes to the construction industry in various ways. Firstly, its high strength and durability make it an ideal material for structural components, such as beams and columns, ensuring the integrity and safety of buildings. Secondly, special steel's resistance to corrosion and extreme weather conditions enhances the longevity of structures, reducing maintenance and replacement costs. Additionally, its versatility allows for innovative designs and efficient construction methods, enabling architects and engineers to push the boundaries of construction possibilities. Overall, special steel plays a crucial role in enhancing the quality, performance, and sustainability of construction projects.

- Q: How does alloy steel improve the strength and toughness of steel?

- Alloy steel improves the strength and toughness of steel by introducing additional elements, such as manganese, chromium, nickel, or molybdenum, into the base iron-carbon composition. These alloying elements enhance the steel's properties by forming solid solutions or precipitates that hinder dislocation movement, increasing the material's strength. Furthermore, they modify the microstructure, resulting in a refined grain size and improved toughness, making the alloy steel more resistant to deformation, wear, and fracture.

Send your message to us

High Carbon High Chromium Steel D2 Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords