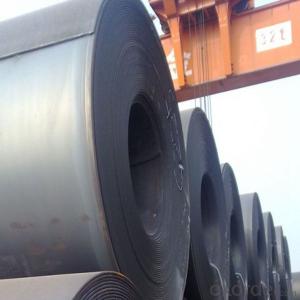

Hot Rolled Steel Coils,Hot Rolled Steel Plates SS400

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

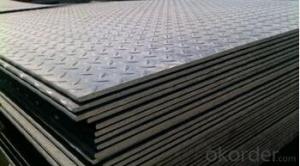

DESCRIPTION FOR SS400 CARBON STEEL SHEET

1.Thickness: 1-200mm

2.Width: 100-3000mm

3.Length: 1000-12000mm

4. Applications :mining machinery, environmental protection, engineering

5. Grade:SS400 A 36 Q195.Q235.Q345.SPCC.SPCH

6.Surface : Hot Rolled Cold Rolled Galvanized Steel

DESCRIPTION FOR CARBON STEEL PLATE

Product | carbon steel plate price per ton |

Place of origin | Tianjin,China mainland |

MOQ | 25 tons |

Thickness | 1mm-200mm |

Width | 1000mm-3000mm |

Length | 1000mm-2000mm |

Application | widely |

Standard | AISI,ASTM,BS,DIN,JIS,GB,etc |

Grade | A572,A573,A633,A678,A709,A710,G3101,G3136,etc |

Tpye | Steel plate |

Surfacing | Coated |

Productive Technology | Hot Rolled & Cold Rolled |

Price | FOB USD 500-900 per ton |

Port | TIANJIN,SHANGHAI |

Payment Terms | L/C,T/T,Western Union,MoneyGram |

Product Ability | 1000 tons per month |

Delivery | 10 days after deposit or according to customers' quantity |

Packing | standard seaworthy export packing or as the request of customers |

DETAILS:

Thickness | 0.5-100mm |

Width | 1250mm,1500mm,1800mm,2000mm.,2500mm or as required |

Length | 2000-12000mm |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material | A36,SS400,SPCC,SPHC, Q195, Q 235,Q345 |

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

DETAILED PICTURES FOR STEEL COILS

FAQ:

Q:You are Factory or Trading Company?

A:We are factory,our main products include Steel plate,Steel Bar,Steel coils.

Q:What’s the MOQ?

A:Generally,the trail order will be accepted.The MOQ can be confirmed according to the different products.For example,the MOQ of rebar will be 25-50MT,the galvanized steel pipe will be 10MT,the stainless steel pipe will 1-5MT.

- Q: Can stainless steel sheets be bent?

- Stainless steel sheets have the capability to be bent. This material, known for its versatility, can be molded into different forms and designs, including bends. The capacity to bend stainless steel sheets relies on their thickness and composition. Generally, thinner sheets are more pliable and easier to bend, whereas thicker sheets might necessitate specialized tools and techniques. It is crucial to bear in mind that the bending procedure could potentially weaken the strength and durability of the stainless steel sheet. Therefore, careful thought should be given to the particular application and requirements before embarking on the bending of stainless steel sheets.

- Q: Can stainless steel sheets be used for fireplaces?

- Yes, stainless steel sheets can be used for fireplaces. Stainless steel is a popular material for fireplace construction due to its high resistance to heat and corrosion. It is durable and can withstand the extreme temperatures generated by a fireplace, making it a suitable choice for both indoor and outdoor fireplaces. Additionally, stainless steel sheets can be customized and fabricated to fit any fireplace design, offering versatility in aesthetics and functionality.

- Q: Are stainless steel sheets suitable for automotive applications?

- Yes, stainless steel sheets are suitable for automotive applications. They are widely used in the automotive industry due to their durability, corrosion resistance, and high strength-to-weight ratio. Stainless steel sheets provide excellent protection against rust and can withstand harsh conditions, making them ideal for various automotive components such as exhaust systems, body panels, and structural parts.

- Q: What are the main chemical constituents of stainless steel plates?

- Stainless steel is often divided into martensitic steel, ferritic steel, austenitic steel, austenitic ferrite (duplex) stainless steel and precipitation hardening stainless steel according to the state of the organization. In addition, can be divided into components: chromium stainless steel, chromium nickel stainless steel and chromium, manganese, nitrogen, stainless steel and so on.

- Q: Can stainless steel sheets be used for bus shelters?

- Yes, stainless steel sheets can be used for bus shelters. Stainless steel is a durable and weather-resistant material, making it suitable for outdoor applications like bus shelters. It offers longevity, easy maintenance, and a modern aesthetic.

- Q: What are the bending limits of stainless steel sheets?

- The bending limits of stainless steel sheets depend on several factors such as the grade of stainless steel, thickness of the sheet, and the specific type of bending process being used. Stainless steel sheets are known for their excellent strength and durability, which allows them to be bent to a certain extent without breaking or cracking. In general, stainless steel sheets can be bent to a radius that is at least twice the thickness of the sheet. For example, if the sheet is 1mm thick, it can typically be bent to a minimum radius of 2mm. However, it is important to note that this is just a general guideline and the actual bending limits may vary depending on the specific grade of stainless steel. Certain grades of stainless steel, such as 304 and 316, have higher yield strengths and are more resistant to deformation, making them suitable for more severe bending applications. Thicker sheets also have higher bending limits compared to thinner ones, as they have more material to withstand the bending forces. It is also worth mentioning that the type of bending process used can affect the bending limits of stainless steel sheets. Processes like press brake bending and roll bending are commonly used for bending stainless steel sheets. These processes utilize different techniques and equipment, which can result in varying bending limits. To determine the exact bending limits for a specific grade and thickness of stainless steel sheet, it is best to consult the manufacturer's specifications or seek guidance from a professional metal fabricator. They can provide accurate information and guidance on the bending capabilities of stainless steel sheets for your specific application.

- Q: Can stainless steel sheets be used for kitchen countertops?

- Yes, stainless steel sheets can be used for kitchen countertops. Stainless steel is a popular choice for kitchen countertops due to its durability, heat resistance, and hygienic properties. It is resistant to stains, corrosion, and rust, making it a suitable material for a high-traffic area like the kitchen. Stainless steel countertops are also easy to clean and maintain, making them a practical option for busy kitchens. Additionally, stainless steel adds a sleek and modern look to the kitchen, making it a popular choice for contemporary and industrial-style kitchens.

- Q: Are stainless steel sheets resistant to alkaline solutions?

- Yes, stainless steel sheets are generally resistant to alkaline solutions.

- Q: What is the weight of stainless steel sheets?

- The weight of stainless steel sheets may differ based on their thickness and dimensions. Typically, stainless steel sheets possess a density of 8 grams per cubic centimeter. To determine the weight of a stainless steel sheet, one must acquire the dimensions (length, width, and thickness) and multiply them to ascertain the volume. Subsequently, the weight can be determined by multiplying the volume by the density.

- Q: What is stainless steel plate wire?

- A filament is a unit of length.In mathematics 10 decimillimeter centimillimeter decimillimeter =1 mm, 10 =1

Send your message to us

Hot Rolled Steel Coils,Hot Rolled Steel Plates SS400

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords