Hot Rolled Plate Steel JIS SS400 Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION:

GRADE: SS400, ASTM A36, A572, ST37,ST52, Q195, Q215, Q235,Q345, S235JR etc.

STANDARD: GB/T709-2006, ASTM A36, JIS G3101, DIN EN 10025, SAE 1045, ASTM A570

SPEC: 1)Width: 600-2500mm or 1000,1050,1250,1500,1800,2000mm

2)Thickness:1.5mm-200mm or as customers’ special requirements;

3)Length: 2-12m or as customers’ special requirements

Product | carbon steel plate price per ton |

Place of origin | Tianjin,China mainland |

MOQ | 25 tons |

Thickness | 1mm-200mm |

Width | 1000mm-3000mm |

Length | 1000mm-2000mm |

Application | widely |

Standard | AISI,ASTM,BS,DIN,JIS,GB,etc |

Grade | A572,A573,A633,A678,A709,A710,G3101,G3136,etc |

Tpye | Steel plate |

Surfacing | Coated |

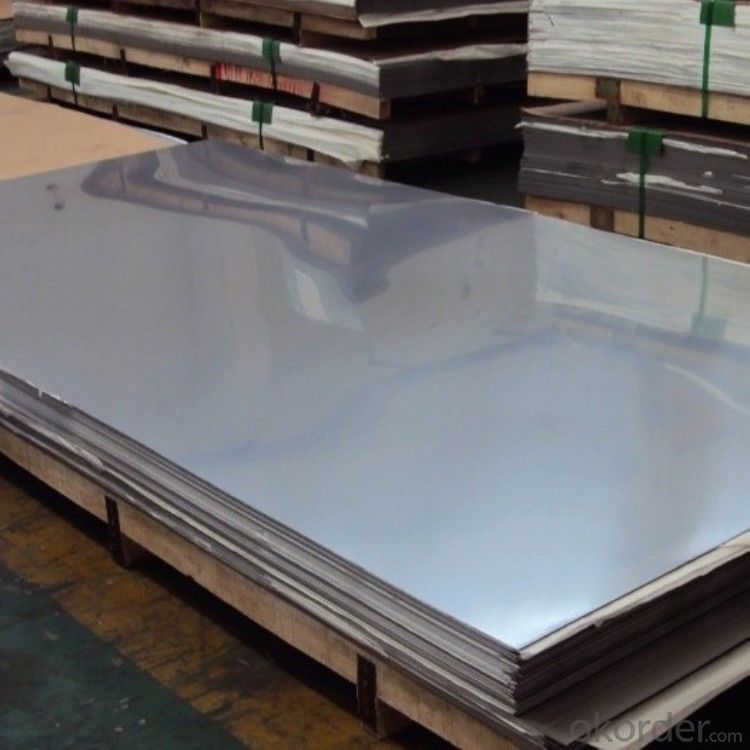

Productive Technology | Hot Rolled & Cold Rolled |

Price | FOB USD 500-900 per ton |

Port | TIANJIN,SHANGHAI |

Payment Terms | L/C,T/T,Western Union,MoneyGram |

Product Ability | 1000 tons per month |

Delivery | 10 days after deposit or according to customers' quantity |

Packing | standard seaworthy export packing or as the request of customers |

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

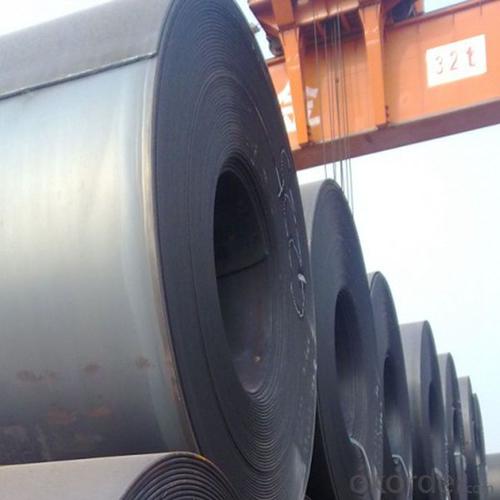

DETAILED PICTURES FOR STEEL COILS

FAQ

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: Can steel sheets be used for elevator shafts?

- Yes, steel sheets can be used for elevator shafts. Steel is a widely used material for constructing elevator shafts due to its durability, strength, and fire-resistant properties. Steel sheets are commonly used to create the walls and floors of elevator shafts, providing structural support and ensuring the safety of the elevator system. They can be easily fabricated, allowing for precise customization to fit the specific dimensions and design requirements of the elevator shaft. Additionally, steel sheets can be treated with various coatings to prevent corrosion and enhance their longevity. Therefore, steel sheets are a suitable choice for constructing elevator shafts, offering a reliable and robust solution for vertical transportation systems.

- Q: How do steel sheets perform in terms of weather resistance?

- Steel sheets are highly weather-resistant due to their inherent strength and durability. They can withstand various weather conditions such as rain, snow, extreme temperatures, and UV exposure without deteriorating or losing their integrity. Additionally, steel sheets are resistant to corrosion, which further enhances their longevity and ability to withstand harsh weather conditions.

- Q: How do steel sheets perform in terms of weather resistance?

- Steel sheets are known for their exceptional weather resistance properties. Due to their composition and protective coatings, steel sheets are highly resistant to various weather conditions such as rain, snow, and wind. They have the ability to withstand extreme temperatures, both hot and cold, without any significant deterioration or damage. Additionally, steel sheets are also highly resistant to corrosion, making them an ideal choice for outdoor applications and areas with high humidity or saltwater exposure. The weather resistance of steel sheets helps to ensure their longevity and durability, making them a reliable option for various construction and industrial purposes.

- Q: Are steel sheets suitable for food processing facilities?

- Yes, steel sheets are suitable for food processing facilities. Steel is a durable and hygienic material that is resistant to corrosion, easy to clean, and can withstand high temperatures. It is commonly used in food processing facilities to ensure food safety and maintain a clean and sanitary environment.

- Q: How long do steel sheets last?

- Steel sheets can last for many years, often surpassing the lifespan of other materials. The longevity of steel sheets depends on various factors such as the quality of the steel, the conditions it is exposed to, and how well it is maintained. In general, high-quality steel sheets that are properly installed and maintained can last for several decades or even longer. However, if steel sheets are exposed to harsh environments, such as extreme temperatures, humidity, or corrosive substances, their lifespan may be reduced. Regular inspections, cleaning, and maintenance can help extend the lifespan of steel sheets and ensure their durability over time.

- Q: What are the advantages of using steel sheets in automotive manufacturing?

- There are several advantages of using steel sheets in automotive manufacturing. Firstly, steel sheets provide high strength and durability, making them ideal for withstanding the harsh conditions and stresses experienced by vehicles on the road. This strength allows for safer and more reliable vehicles, as steel sheets provide a strong protective structure that can absorb impact energy in the event of a collision. Secondly, steel sheets offer excellent formability, which means they can be easily shaped and molded into various complex designs required for automotive parts. This versatility allows for the creation of intricate and precise components, ensuring a perfect fit and optimal performance. Additionally, steel sheets have good corrosion resistance properties, which is crucial for automotive applications. Vehicles are subjected to various environmental factors such as moisture, salt, and chemicals, which can lead to rust and corrosion. By using steel sheets with protective coatings, manufacturers can ensure that their vehicles have a longer lifespan and maintain their aesthetic appeal. Moreover, steel sheets are readily available and cost-effective compared to other materials used in automotive manufacturing. Steel is a widely used material in various industries, which means there is a well-established supply chain for steel sheets. This availability not only guarantees a consistent supply for automotive manufacturers but also helps keep production costs manageable. Lastly, steel sheets provide excellent thermal conductivity, which is essential for heat dissipation in automotive applications. Vehicles generate a significant amount of heat, especially in the engine and exhaust systems. Steel sheets help in efficiently transferring and dissipating this heat, preventing overheating and ensuring optimal performance. In conclusion, the advantages of using steel sheets in automotive manufacturing include high strength and durability, excellent formability, good corrosion resistance properties, cost-effectiveness, and efficient heat dissipation. These factors make steel sheets a preferred choice for producing safe, reliable, and long-lasting vehicles.

- Q: What is the specific heat capacity of steel sheets?

- The specific heat capacity of steel sheets varies depending on the specific type of steel being used. However, on average, the specific heat capacity of steel ranges from 460 to 520 joules per kilogram per degree Celsius (J/kg°C).

- Q: What are the common sizes of steel sheets available in the market?

- The common sizes of steel sheets available in the market vary, but some standard sizes include 4x8 feet, 4x10 feet, and 5x10 feet. These sizes are widely used in various industries and can be easily found in steel suppliers or hardware stores.

- Q: Are the steel sheets suitable for shipbuilding?

- Yes, steel sheets are highly suitable for shipbuilding. Steel is a versatile and durable material that possesses excellent properties for marine applications. It has a high strength-to-weight ratio, allowing for the construction of robust and sturdy vessels while keeping the overall weight low. Steel sheets also have high tensile strength, which ensures the ship's structural integrity and resistance to forces exerted by waves, wind, and other external factors. Additionally, steel is highly resistant to corrosion, making it ideal for withstanding the harsh saltwater environment. Its fire-resistant properties further enhance the safety of ships. Given these advantages, steel sheets are widely used in shipbuilding and have proven to be reliable and efficient in constructing various types of vessels, from cargo ships to cruise liners and naval warships.

- Q: Are steel sheets suitable for oil rig platforms?

- Yes, steel sheets are suitable for oil rig platforms. Steel is widely used in the construction of oil rig platforms due to its exceptional strength and durability. Oil rig platforms are subjected to harsh environmental conditions, such as extreme temperatures, high winds, and corrosive saltwater, and steel has proven to be able to withstand these conditions effectively. Steel sheets provide a strong and stable foundation for the oil rig platforms, ensuring that they can support the weight of the rig, equipment, and personnel. The high strength of steel allows for the construction of large and complex structures while maintaining stability and safety. Furthermore, steel is highly resistant to corrosion, making it an ideal material for offshore applications. The oil rig platforms are constantly exposed to saltwater, which can cause corrosion and weaken other materials. Steel sheets, however, can be specially treated with protective coatings to enhance their resistance to corrosion and extend their lifespan. In addition to its strength and corrosion resistance, steel is also a versatile material that can be easily shaped and fabricated into various components required for oil rig platforms. This flexibility allows for efficient and cost-effective construction processes, reducing both time and resources required for installation and maintenance. Overall, steel sheets are a suitable choice for oil rig platforms due to their strength, durability, corrosion resistance, and versatility. They provide a reliable and robust foundation for offshore drilling operations, ensuring the safety and longevity of the platform in challenging environments.

Send your message to us

Hot Rolled Plate Steel JIS SS400 Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords