Special Steel Tool Steel 1.2510 Material,SKS3 Material steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Special Steel Tool Steel 1.2510 Material,SKS3 Material steel

Product information:

Specifications

-Delivery stock within 10 days

-ISO9001 certified factory

-Low price and high quality

-Flexible MOQ and payment

SKS3 mold steel

Diameter: 12-600mm

Length: 2000-4000mm

Surface condition of 1.2510 SKS3 mold steel

black/polished/machined/peeled/grinded/turned

Applications of 1.2510 SKS3 mold steel

1.2510 is used in cutting and punching toolsshear knives,thread rolling tools,measuring instruments platinum using molds.

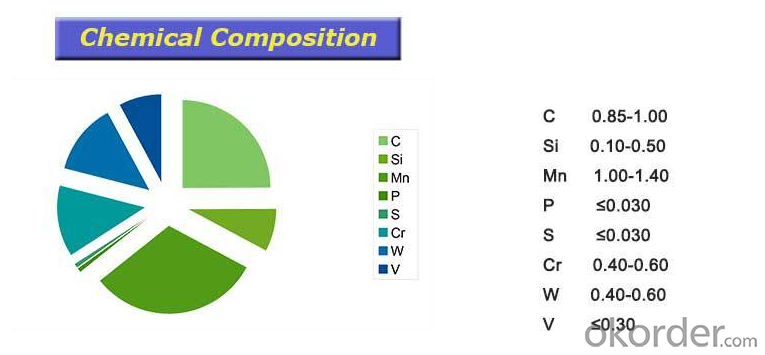

| Chemical Composition(%) | |||||||

| C | Si | Mn | P | S | Cr | V | W |

| 0.85-1.00 | 0.10-0.50 | 1.00-1.40 | ≤0.030 | ≤0.030 | 0.40-0.60 | ≤0.30 | 0.40-0.60 |

| Specialty | |||||||

Refined steel of vacuum and take-off air, the quality of steel is pure; deliver products after anneal, steel products are easy to be cut and machined; the rigidity is high after quench, good endurance; the dimension is stable, small distortion. | |||||||

| Use | |||||||

| 1.All kinds of cutting tools, pressing mold, wood-FT mold, screw thread tools, plastic molds. | |||||||

| Heat Treatment | |||||||

| 1.To anneal after eliminate stress: 600-650°c | |||||||

| 2.Quench: 800-840 °c oil cooling | |||||||

| 3.Re- tempering: 180-200`C air cooling | |||||||

| Melting Process | |||||||

| 1. EAF: Electric Furnace+LF+VD(Optional) | |||||||

| 2. ESR: Electric Furnace+LF+VD+Eleroslag Remelted(Optional) | |||||||

| UT Class | |||||||

| According to Standard of SEP 1921/84,100% Volume, Level C/c, D/d or E/e | |||||||

| Tolerance on Quantity | |||||||

| +/-10% Per Size | |||||||

Other product show:

Our workshop show:

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

- Q: How does special steel contribute to the medical aftermarket industry?

- The medical aftermarket industry heavily relies on special steel, which is essential for producing top-quality materials needed for medical devices and equipment. Special steel, also known as stainless steel, offers a wide range of advantages that make it perfect for medical applications. Above all, special steel's resistance to corrosion and rust is of utmost importance in the medical field, where hygiene and cleanliness are crucial. Medical devices like surgical instruments, implants, and equipment require frequent sterilization, and the corrosion resistance of special steel guarantees their durability and long-lasting nature. Moreover, special steel possesses exceptional strength and hardness properties, making it suitable for medical implants and prosthetics. These implants must be able to withstand the stresses and strains of the human body while maintaining their structural integrity. Special steel provides the necessary strength and toughness required for these critical applications. Furthermore, special steel is biocompatible, meaning it does not cause any negative reactions or toxicity when it comes into contact with living tissues. This characteristic is vital for implants and devices that directly interact with the human body, as it minimizes the risk of rejection or allergic reactions. Additionally, special steel's versatility allows for easy machining and fabrication into complex shapes and sizes, meeting the diverse requirements of medical applications. It can be shaped into delicate surgical instruments, precise cutting tools, and even large-scale equipment like hospital beds and imaging machines. The high precision and dimensional stability of special steel contribute to the accuracy and reliability of medical devices, especially in areas like diagnostics and imaging. Precise measurements and high-quality images are essential for accurate diagnosis and treatment planning, and special steel helps achieve these goals. In conclusion, special steel's corrosion resistance, strength, biocompatibility, and versatility make it an invaluable material in the medical aftermarket industry. Its use in manufacturing medical devices and equipment ensures the highest standards of hygiene, durability, and performance, ultimately contributing to the advancement of healthcare and improving patient outcomes.

- Q: How does special steel contribute to the chemical processing industry?

- The chemical processing industry heavily relies on special steel, which offers a wide range of benefits that enhance the efficiency and safety of various processes. One crucial characteristic of special steel is its high resistance to corrosion, which is vital when dealing with corrosive chemicals. This resistance ensures that equipment and pipelines made from special steel can endure harsh chemical environments without deteriorating, leading to longer lifespan and reduced maintenance costs. Moreover, special steel exhibits exceptional strength and durability, enabling it to withstand the high temperatures and pressures commonly encountered in chemical processing. This strength guarantees that equipment like reactors, heat exchangers, and vessels can function effectively under demanding conditions, minimizing the likelihood of failures or accidents. Additionally, special steel possesses excellent thermal conductivity, making it highly advantageous in heat transfer applications. This property facilitates efficient heat exchange between different fluids, thereby enhancing the overall energy efficiency of chemical processes. By enabling effective heat transfer, special steel optimizes the performance of equipment such as condensers, boilers, and evaporators. Furthermore, special steel is frequently utilized in the construction of storage tanks and pipelines for the transportation and distribution of chemicals. Its remarkable resistance to mechanical stress and impact makes it ideal for ensuring the secure containment and transportation of hazardous substances, reducing the risk of leaks or spills that could have severe environmental and safety consequences. In conclusion, the utilization of special steel in the chemical processing industry significantly contributes to the reliability, efficiency, and safety of various processes. Its resistance to corrosion, strength, thermal conductivity, and durability make it an essential material for equipment and infrastructure, guaranteeing the smooth and secure operation of chemical processing plants.

- Q: Is special steel magnetic?

- Yes, special steel can be magnetic. The magnetism of steel depends on its composition and the presence of certain elements, such as iron, nickel, and cobalt. Special steels that contain these magnetic elements can exhibit magnetic properties. However, not all types of steel are magnetic. Some stainless steels, for example, have a higher content of non-magnetic elements like chromium, which reduces their magnetic properties. So, whether a specific type of special steel is magnetic or not will depend on its composition.

- Q: What are the environmental considerations of using special steel?

- Special steel production has significant environmental considerations. The extraction and processing of raw materials, such as iron and coal, contribute to deforestation, habitat destruction, and greenhouse gas emissions. Moreover, the high energy requirements during steel production result in carbon dioxide emissions, contributing to climate change. Special steel also often requires the use of alloying elements, such as chromium and nickel, which can lead to toxic waste and pollution if not properly managed. Therefore, careful monitoring and implementation of sustainable practices are crucial to minimize the environmental impact associated with using special steel.

- Q: How does special steel perform in case hardening applications?

- Special steel performs exceptionally well in case hardening applications. Case hardening is a heat treatment process used to increase the surface hardness of a material while maintaining a tough and ductile core. Special steel, also known as alloy steel, is specifically formulated to have enhanced properties such as high strength, toughness, and wear resistance. In case hardening applications, special steel is ideal due to its ability to form a hard outer layer while retaining its core properties. The process typically involves heating the steel to a specific temperature and then introducing a carbon-rich environment, such as through carburizing or carbonitriding. The carbon atoms diffuse into the steel's surface, creating a high-carbon layer, known as the case, which significantly increases hardness and wear resistance. Special steel's high carbon content allows for deeper and more uniform case hardening compared to other types of steel. This results in improved durability, reduced friction, and enhanced resistance to wear, abrasion, and impact. The tough core of special steel also ensures that the material remains resistant to cracking or fracturing under high stress or impact loads. Additionally, special steel offers excellent machinability, allowing for ease of processing during case hardening applications. This makes it a preferred choice for various industries, including automotive, aerospace, tooling, and manufacturing, where components require both high surface hardness and structural integrity. Overall, special steel is highly regarded for its exceptional performance in case hardening applications. Its combination of high strength, toughness, wear resistance, and machinability makes it an excellent choice for producing durable and reliable components that can withstand demanding operating conditions.

- Q: Can special steel be used in the textile industry?

- Yes, special steel can be used in the textile industry. Special steel, such as stainless steel, can be utilized in various textile machinery components like needles, pins, and cutting tools due to its durability, corrosion resistance, and high strength. Additionally, special steel wire can be used in weaving, knitting, and braiding processes to enhance the strength and performance of textile products.

- Q: What are the characteristics of high-speed steel?

- High-speed steel is known for its exceptional hardness, toughness, and wear resistance. It can withstand high temperatures without losing its cutting ability, making it ideal for applications that involve high-speed or continuous cutting. Additionally, high-speed steel retains its hardness even at elevated temperatures, ensuring prolonged tool life. Its ability to maintain its cutting edge even under extreme conditions makes it a preferred choice in industries such as metalworking, aerospace, and automotive.

- Q: Can special steel be used in corrosive environments?

- Yes, special steel can be used in corrosive environments. Special steel alloys are specifically designed to have enhanced resistance to corrosion caused by various elements such as moisture, chemicals, or saltwater. These alloys are carefully formulated with specific elements, such as chromium or nickel, which create a protective layer on the surface of the steel, preventing or minimizing corrosion. As a result, special steel is widely utilized in industries such as marine, oil and gas, chemical processing, and wastewater treatment, where exposure to corrosive environments is prevalent.

- Q: How does special steel contribute to the manufacturing of power generation equipment?

- Special steel plays a crucial role in the manufacturing of power generation equipment due to its unique properties and characteristics. Its exceptional strength, durability, and resistance to corrosion and high temperatures make it an ideal material for various components used in power plants, including turbines, boilers, and generators. Special steel's ability to withstand extreme conditions ensures the reliability and efficiency of power generation equipment, contributing to the overall performance and longevity of power plants.

- Q: Can special steel be used in the production of musical instruments?

- Yes, special steel can be used in the production of musical instruments. It is commonly used for strings, guitar frets, and some wind instrument components due to its specific acoustic properties and durability.

Send your message to us

Special Steel Tool Steel 1.2510 Material,SKS3 Material steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords