Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard

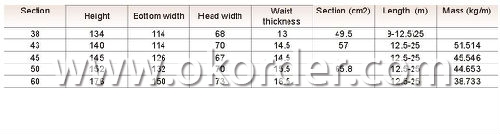

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg

Production Standard: GB2585-81, AREMA, DIN, JIS, EN, etc.

Length: 6M-25M as the requriement of the client

Material: 50Mn, U71Mn, 900A, R260, etc.

Grade | Element(%) | ||||

C

| Mn | S

| P

| Si

| |

U71Mn

|

0.65—0.76 |

1.10—1.40 |

≤0.030 |

≤0.035

|

0.15-0.35

|

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Applications of Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track. Be used for railway, subway, curve way, tunnel way, etc.

Packaging & Delivery of Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: Why buy Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What is the normal tolerance of Hot Rolled Mild Steel Angle Beams for Structures and for Buildings?

A3: Normally 3%-5%, but we can also produce the goods according to the customers' request

- Q: What are the safety measures for workers during steel rail maintenance?

- Some safety measures for workers during steel rail maintenance include wearing personal protective equipment such as helmets, safety glasses, gloves, and high-visibility clothing. Workers should also receive proper training on the safe use of tools and equipment, as well as procedures for working at heights or in confined spaces. Regular inspections and maintenance of equipment and tools are necessary to ensure their safe operation. Additionally, workers should be trained on emergency response procedures and have access to first aid kits and fire extinguishers. Following proper safety protocols, such as barricading work areas and implementing proper signage, is crucial to minimize the risk of accidents.

- Q: How are steel rails protected against animal intrusion?

- Steel rails are typically protected against animal intrusion through various measures such as fences, barriers, or deterrents. These preventive measures help to minimize the risk of animals, like wildlife or livestock, wandering onto the railroad tracks and causing potential accidents or disruptions to train operations.

- Q: Are steel rails affected by seismic activities or ground movements?

- Yes, steel rails can be affected by seismic activities or ground movements. Seismic activities such as earthquakes can cause ground shaking and horizontal movement, which can lead to the displacement or damage of steel rails. Additionally, ground movements like landslides or soil settlements can also impact the stability and alignment of steel rails. Therefore, it is important to consider these factors when designing and maintaining railway infrastructure in seismically active areas.

- Q: What's the difference between a high-speed rail and an ordinary one?

- Not only does the train speed run faster than the train, but the infrastructure (track, signal, communication and catenary) of the train also meets the technical requirements of the speed grade.

- Q: How do steel rails contribute to train ride quality?

- Steel rails contribute to train ride quality in several ways. Firstly, steel rails provide a smooth and stable surface for the train wheels to roll on, ensuring minimal friction and vibration during the journey. This results in a comfortable and quiet ride for passengers. Additionally, steel rails are highly durable and can withstand heavy loads, reducing the risk of derailment and improving overall safety. The precise alignment and maintenance of steel rails also help to minimize bumps and jolts, further enhancing the ride quality for passengers.

- Q: What are the pros and cons of using steel rails in railway construction?

- Pros of using steel rails in railway construction include: 1. Durability: Steel rails have a high level of durability, able to withstand heavy loads and extreme weather conditions. This makes them ideal for long-term use in railway construction. 2. Strength: Steel rails have excellent strength-to-weight ratio, providing the necessary support and stability for trains to travel at high speeds. 3. Smooth ride: Steel rails offer a smooth and consistent surface for trains to travel on, reducing vibrations and ensuring a comfortable ride for passengers. 4. Low maintenance: Compared to other rail materials, steel rails require relatively low maintenance. They have a longer lifespan and are less prone to wear and tear, reducing the need for frequent replacements or repairs. 5. Versatility: Steel rails can be easily modified and adapted to different track configurations, making them suitable for various railway designs and layouts. Cons of using steel rails in railway construction include: 1. Cost: Steel rails can be more expensive to manufacture and install compared to other rail materials such as concrete or wood. This can add to the overall construction costs of a railway project. 2. Corrosion: Steel is prone to corrosion, especially in humid or coastal environments. Regular maintenance and protective coatings are required to prevent rust formation and ensure the longevity of steel rails. 3. Noise pollution: Steel rails can generate noise when trains pass over them, particularly at higher speeds. This can be a concern for nearby residents and requires additional noise reduction measures, such as installing sound barriers or using noise-dampening track components. 4. Weight limitations: While steel rails are strong, there are weight limitations to consider. Extremely heavy loads or concentrated loads can cause deformation or damage to the rails, necessitating careful planning and monitoring of freight transport. 5. Environmental impact: Steel production has significant environmental implications, including greenhouse gas emissions and energy consumption. The use of steel rails contributes to these impacts, although efforts are being made to develop more sustainable and eco-friendly production processes.

- Q: How are steel rails protected against excessive heat and cold?

- Steel rails are protected against excessive heat and cold through various methods such as thermal expansion joints, insulation materials, and temperature monitoring systems. These measures help prevent rail buckling or contraction due to extreme temperatures, ensuring the safety and durability of the railway infrastructure.

- Q: How do steel rails contribute to the overall reliability of railways?

- The overall reliability of railways is greatly enhanced by steel rails, which contribute in various ways. Firstly, the high strength and durability of steel rails enable them to withstand heavy loads and frequent train traffic, minimizing wear and tear. This ensures the integrity of the rails, reducing the risk of derailments or accidents. Furthermore, steel rails exhibit excellent resistance to corrosion and weathering, even in harsh environmental conditions. This stability and structural integrity are crucial for maintaining a reliable railway system, as it prevents disruptions caused by rail corrosion or degradation. In addition, steel rails provide a consistently smooth surface for train wheels to run on. This uniformity facilitates efficient and stable train movement, minimizing vibrations or unevenness that could impact performance or passenger comfort. Moreover, this smooth running surface reduces wear on train wheels, decreasing maintenance needs and enhancing overall reliability. Moreover, steel rails offer superior track alignment and stability. Careful design and placement ensure proper alignment and gauge, which are essential for safe and efficient train operations. The precise track alignment significantly reduces the risk of derailments or deviations, further enhancing the reliability and safety of the railway network. In summary, steel rails are vital for the overall reliability of railways due to their high strength, durability, corrosion resistance, smooth running surfaces, and precise track alignment. These factors enable safe and efficient train movement, minimizing disruptions and ensuring the smooth functioning of the railway system.

- Q: How do steel rails resist corrosion?

- Steel rails resist corrosion through a process called galvanization, where a protective coating of zinc is applied to the surface. The zinc layer acts as a sacrificial anode, corroding in place of the steel, thereby preventing rust formation and preserving the integrity of the rails.

- Q: What is the impact of steel rails on train fuel efficiency?

- The impact of steel rails on train fuel efficiency is significant and positive. Steel rails provide a smooth and stable surface for the train wheels to roll on, reducing friction and resistance. This, in turn, allows trains to move more efficiently and at higher speeds. The reduced friction between the steel rails and train wheels results in less energy wasted and ultimately leads to lower fuel consumption. Compared to other materials, such as wooden or concrete rails, steel rails offer superior durability and strength. They can withstand heavy loads and maintain their shape and integrity over long distances and extended periods of time. This durability ensures that the train remains on a stable track, minimizing the need for frequent repairs or adjustments. As a result, the train can maintain its momentum and consume less fuel in the process. Furthermore, steel rails have a low coefficient of thermal expansion, meaning they do not expand or contract significantly with temperature changes. This characteristic allows for a more consistent and reliable track alignment, reducing the need for constant realignment and maintenance. The stable track alignment ensures that the train can travel efficiently without unnecessary energy losses due to misalignment or track irregularities. In addition to improving fuel efficiency, steel rails also contribute to overall safety and reliability in train transportation. Their strength and durability help prevent derailments and accidents, ensuring the safety of passengers and cargo. By providing a stable and secure track, steel rails also minimize the risk of train delays and disruptions, enhancing the reliability and punctuality of train services. In conclusion, the impact of steel rails on train fuel efficiency is highly positive. The smooth and stable surface provided by steel rails reduces friction and resistance, allowing trains to move more efficiently and consume less fuel. The durability of steel rails ensures a consistent track alignment, minimizing the need for repairs and maintenance, further optimizing fuel efficiency. Overall, steel rails contribute to safer, more reliable, and environmentally friendly train transportation.

Send your message to us

Hot Rolled Mild Heavy Steel Rials for Minas GB, AREMA, DIN Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords