Hot Rolled I-Beam with Best Quality and Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

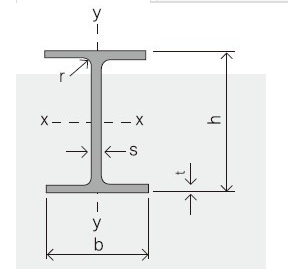

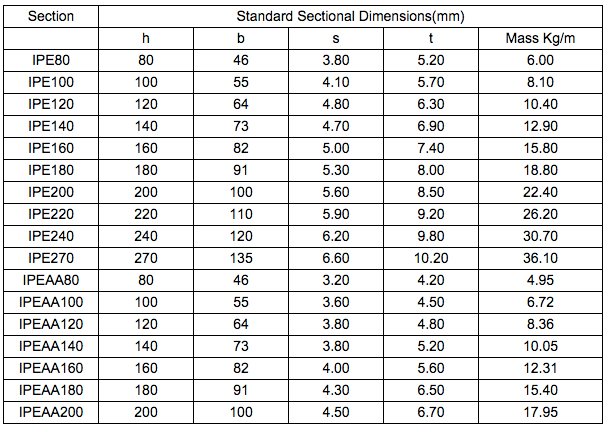

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: What are the different types of steel connections used for composite I-beams?

- There are various types of steel connections commonly used for composite I-beams, including shear connectors, welding, and bolted connections. Shear connectors are typically welded or shot-fired onto the steel beam, allowing for the transfer of shear forces between the steel and concrete components. Welding is another common method, where the steel beam and concrete slab are fused together using heat. Bolted connections involve using bolts to connect the steel beam to the concrete slab, providing flexibility for disassembly and maintenance. Each type of connection offers different advantages and may be selected based on factors such as load capacity, construction requirements, and cost efficiency.

- Q: Are Steel I-Beams fire resistant?

- Yes, steel I-beams are generally considered to be fire resistant due to their high melting point and ability to retain their structural integrity even under extreme heat.

- Q: How do you calculate the lateral torsional buckling strength of a steel I-beam?

- To calculate the lateral torsional buckling strength of a steel I-beam, several factors need to be considered, including the beam's flexural stiffness, moment of inertia, length, and applied load. Follow these step-by-step instructions: 1. Find the critical load: This is the maximum load the beam can handle before experiencing lateral torsional buckling. Use Euler's buckling formula: Critical Load = (π^2 * E * I) / (K * L^2) Where: - E represents the steel's modulus of elasticity - I is the moment of inertia of the beam's cross-section - K is the effective length factor (depends on the beam's end conditions) - L is the unsupported length of the beam 2. Calculate the moment of inertia (I): This measures the beam's resistance to bending. Determine it based on the beam's cross-section geometry (e.g., width, height, and thickness) using standard formulas or structural design tables. 3. Determine the effective length factor (K): This factor depends on the support conditions at the beam ends. Common values are: - Simply supported ends: K = 1.0 - One end fixed, the other end simply supported: K = 0.65 - Both ends fixed: K = 0.5 4. Compute the lateral torsional buckling strength: Once the critical load is known, multiply it by a safety factor, typically specified by design codes or standards. Lateral Torsional Buckling Strength = Critical Load * Safety Factor The safety factor ensures that the beam can safely resist lateral torsional buckling without exceeding its allowable capacity. It's worth noting that this calculation method is a simplified approach, assuming idealized conditions. In practice, other factors like the presence of lateral bracing, beam imperfections, and load distribution should also be taken into account for an accurate determination of the lateral torsional buckling strength of a steel I-beam.

- Q: How do steel I-beams contribute to the overall sustainability of a structure?

- Steel I-beams contribute to the overall sustainability of a structure in various ways. Firstly, they have high strength-to-weight ratios, allowing for efficient use of materials and reducing the amount of steel required, which in turn conserves natural resources. Additionally, steel is 100% recyclable, and I-beams can be easily dismantled and reused, reducing the demand for new materials and minimizing waste. Furthermore, steel I-beams are durable and long-lasting, requiring minimal maintenance over their lifespan, which reduces the need for replacements and further conserves resources. Overall, the use of steel I-beams promotes sustainability by optimizing material efficiency, supporting recycling efforts, and ensuring longevity of the structure.

- Q: Can Steel I-Beams be used for airport hangars?

- Yes, steel I-beams can be used for airport hangars. Steel I-beams are commonly used in construction due to their strength and durability. They provide excellent support for large structures like airport hangars, making them a suitable choice for such applications.

- Q: Excuse me: how to use the steel joist to build the attic and the I-beam to go deep into the load-bearing wall. How many centimeters? Do we need to weld the main reinforcement?

- Channel or I-beam construction. Under normal circumstances, the use of channel steel on the line, but with the bending strength of I-beam will be higher, of course, the cost will be higher, but also occupy more space I-beam height. The advantage of channel steel construction is that it is quick to use. It does not need to wait. The disadvantage is that the channel made attic, when people walk in the above, there will be a certain shaking sound, the smaller channel specifications, the greater the shaking. The adoption of channel steel is a recommended practice.

- Q: Are steel I-beams compatible with other building materials?

- Yes, steel I-beams are compatible with other building materials. They are commonly used in construction projects to provide structural support and can be easily integrated with various materials such as concrete, wood, and brick to create a robust and versatile building framework.

- Q: Can steel I-beams be used in theaters or auditoriums?

- Yes, steel I-beams can be used in theaters or auditoriums. Steel I-beams are commonly used in the construction of large-scale structures like theaters and auditoriums due to their strength and load-bearing capabilities. They provide structural support for the building, allowing for open and spacious designs while ensuring safety and stability.

- Q: What are the different types of steel I-beam connections for roof framing?

- There are several types of steel I-beam connections used for roof framing, including welded connections, bolted connections, and concealed connections. Welded connections involve fusing the beams together using heat, creating a strong and durable connection. Bolted connections use bolts and nuts to secure the beams together, allowing for easier disassembly if needed. Concealed connections are typically used in architectural designs where the connection is hidden from view, providing a sleek and seamless appearance.

- Q: The bridge pier cap beam on the I-beam have what use? What points should we pay attention to?

- The lower part of the structure foundation and pile foundation, beam, pier, beam, beam, bearing pad stone, block, abutment bearing pad stone, all under the block structure and the corresponding soilThe superstructure is prefabricated and installed with beams (plates) prefabricated and installedThe upper structure is filled with a wet joint or a joint between the pier top, the cast-in-place continuous section and the beam (slab)The overall bridge deck and ancillary works include the installation of bearings, bridge deck pavement, inner and outer guardrail expansion jointsProtection works include abutment, cone slope, masonry and filling

Send your message to us

Hot Rolled I-Beam with Best Quality and Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords