Hot Rolled I-Beam Steel with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

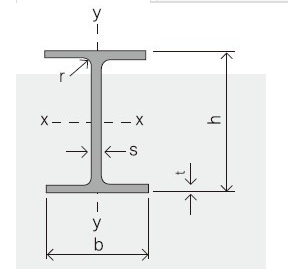

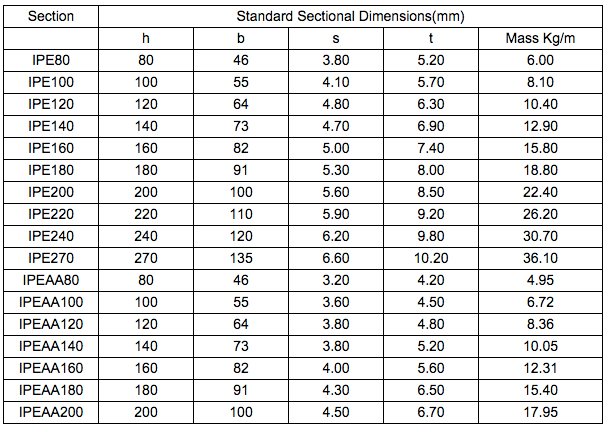

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

Q3: What is the normal tolerance of your steel products ?

A3: Normally 7%-9%, but we can also produce the goods according to the customers' requests.

Images:

- Q: How do you calculate the shear stress in a steel I-beam?

- To determine the shear stress in a steel I-beam, the maximum shear force acting on the beam and the beam's cross-sectional area must be calculated. The shear stress can be obtained using the formula: Shear Stress = Force / Area. In order to find the maximum shear force, an analysis of the loads and supports applied to the beam is necessary. The loads, including the weight applied on the beam, must be considered, and the reactions at the supports must be determined. By applying equilibrium equations, the maximum shear force acting on the beam can be found. Once the maximum shear force has been determined, the cross-sectional area of the beam needs to be calculated. The cross-sectional area is the result of multiplying the beam's width (b) and height (h). It is important to take into account the different dimensions of the flanges and the web for an I-beam. With both the maximum shear force and the cross-sectional area determined, the shear stress can be calculated by dividing the force by the area, using the aforementioned formula. It is worth noting that shear stress calculations also rely on the material properties of the steel, such as its yield strength and ultimate strength. These properties can be obtained from material specifications or reference tables. It is essential to compare the calculated shear stress with the allowable shear stress of the steel to ensure that the beam is designed within its safe limits.

- Q: Are there any environmental concerns associated with the production of steel I-beams?

- There are various environmental issues connected to the manufacturing of steel I-beams. Firstly, a significant amount of energy is necessary for steel production. This energy is often obtained from non-renewable sources like coal or natural gas, which contribute to greenhouse gas emissions and climate change. Extracting and transporting these fossil fuels also have negative effects on the environment, including destroying habitats, polluting the air, and contaminating water sources. Furthermore, the process of converting iron ore into steel involves multiple stages that can generate pollution and waste. For instance, extracting iron ore can result in deforestation, habitat destruction, and soil erosion. Mining also requires water, and if not properly managed, it can lead to water pollution and depletion. Moreover, producing steel I-beams entails a method called steelmaking, typically employing blast furnaces or electric arc furnaces. These furnaces release pollutants like carbon monoxide, sulfur dioxide, and nitrogen oxides, contributing to air pollution and acid rain. The steelmaking process also produces solid waste, including slag and dust, which may contain heavy metals and pose risks to human health and the environment if not adequately handled. Lastly, the transportation of steel I-beams can also cause environmental impacts. Due to their weight and size, large trucks or ships are often required for transportation, consuming fossil fuels and adding to air pollution and greenhouse gas emissions. To address these environmental concerns, efforts have been made to enhance the efficiency of steel production processes, reduce emissions, and promote the use of recycled steel. Recycling steel can significantly decrease energy and raw material requirements, as well as the associated environmental impacts. Additionally, advancements in technology and the adoption of cleaner energy sources can help minimize the carbon footprint of steel production.

- Q: Can steel I-beams be used in offshore platform construction?

- Certainly, the utilization of steel I-beams is feasible in the construction of offshore platforms. Due to their robustness and resilience, steel I-beams are frequently employed in this context. Given the adverse environmental factors encountered in offshore settings, such as strong winds, towering waves, and corrosive seawater, steel I-beams possess the capacity to endure these demanding conditions and offer indispensable structural reinforcement for the platform. Moreover, the simplicity of fabricating and assembling steel I-beams renders them an advantageous option for offshore platform construction.

- Q: How do steel I-beams perform in terms of thermal conductivity?

- Steel I-beams are renowned for their remarkable thermal conductivity, which refers to a material's capacity to conduct heat. Steel, being one of the most commonly utilized thermally conductive materials in construction, ensures that heat can be proficiently transferred from one location to another. The impressive thermal conductivity of steel I-beams renders them ideal for situations that necessitate or desire heat transfer. In the context of buildings, steel I-beams play a crucial role in evenly distributing heat throughout the structure, thereby guaranteeing a consistently comfortable temperature in various areas. This advantage proves particularly beneficial in sprawling commercial buildings or industrial facilities where maintaining a steady temperature is vital for productivity or occupant comfort. Furthermore, the high thermal conductivity of steel I-beams also makes them suitable for applications that require heat dissipation or removal. For instance, they can be effectively employed in heat exchangers or cooling systems, where their efficient heat conduction capabilities enable the rapid transfer of thermal energy. Nevertheless, it is essential to acknowledge that the notable thermal conductivity of steel I-beams can present challenges in certain scenarios. In regions characterized by extreme temperature variations, these I-beams may facilitate the transfer of heat from warmer to cooler areas, potentially resulting in energy loss and escalated heating or cooling expenses. In such cases, it may be necessary to incorporate additional insulation or thermal barriers to minimize heat transfer. To summarize, steel I-beams possess exceptional thermal conductivity, allowing for efficient heat transfer. This characteristic renders them suitable for applications that require heat distribution or dissipation, although certain situations may warrant additional considerations to optimize energy efficiency.

- Q: Can steel I-beams be used for telecommunications towers?

- Yes, steel I-beams can be used for telecommunications towers. Steel I-beams are commonly used in the construction industry due to their strength, durability, and ability to support heavy loads. In the case of telecommunications towers, which require robust and stable structures to support the antennas and equipment, steel I-beams are an ideal choice. They provide the necessary strength and stability to withstand harsh weather conditions, such as strong winds, and can be designed to accommodate the specific height and load requirements of the telecommunications tower. Additionally, steel I-beams can be fabricated off-site and easily transported to the tower location, making them a cost-effective and efficient option for constructing telecommunications towers.

- Q: Does the welding of I-beam affect its structure after welding?

- Any steel after welding has an impact on its structure, only to see what the purpose.

- Q: Can steel I-beams be used for industrial platforms or catwalks?

- Absolutely, industrial platforms or catwalks can indeed utilize steel I-beams. Renowned for their robustness and resilience, steel I-beams present an exceptional option for such purposes. Their capacity to uphold substantial weights and endure continuous pedestrian movement, alongside other industrial operations commonly observed on platforms or catwalks, further solidifies their suitability. Moreover, steel I-beams offer the advantage of effortless customization to meet precise design and structural prerequisites, thereby facilitating efficient and secure construction of industrial platforms or catwalks.

- Q: What are the common methods of protecting steel I-beams from seismic forces?

- There are several common methods of protecting steel I-beams from seismic forces. One of the most common methods is to use specialized seismic bracing systems. These systems consist of additional steel elements or braces that are specifically designed to absorb and dissipate the energy generated during an earthquake. The braces are strategically placed to provide lateral support to the I-beams, preventing them from buckling or collapsing under the seismic forces. Another method is to reinforce the I-beams by adding steel plates or angles to their flanges. These additional elements increase the overall strength and stiffness of the beams, making them more resistant to seismic forces. This method is often used in conjunction with other reinforcement techniques to provide a comprehensive protection system. In some cases, engineers may also choose to install dampers or shock absorbers at the connections between the I-beams and other structural elements. These devices help to dissipate the energy generated during an earthquake, reducing the impact on the I-beams and minimizing the potential for damage. In addition to these methods, proper design and detailing of the steel I-beams can play a crucial role in protecting them from seismic forces. Engineers must consider factors such as the anticipated ground motion, the weight and configuration of the structure, and the specific requirements of the building code to ensure that the I-beams are adequately protected. Overall, a combination of seismic bracing systems, reinforcement techniques, and careful design considerations are commonly employed to protect steel I-beams from seismic forces. These methods help to ensure the structural integrity of the beams and minimize the risk of damage during an earthquake.

- Q: Are steel I-beams flexible or rigid?

- Steel I-beams are rigid.

- Q: How do steel I-beams perform in terms of impact insulation?

- Typically, impact insulation purposes do not involve the use of steel I-beams. These beams are primarily employed for structural support in construction projects. Nevertheless, their rigid and dense nature may offer some degree of impact resistance. When faced with an impact, steel I-beams are engineered to endure the force and disperse it along their length, thereby minimizing the impact's influence on the surrounding structure. Nonetheless, their capacity to absorb or mitigate impact energy is limited when compared to materials specifically designed for impact insulation, such as foam or rubber. If impact insulation is an essential requirement, it is advisable to explore alternative materials or methods that are explicitly intended for this purpose.

Send your message to us

Hot Rolled I-Beam Steel with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords