Hot Rolled Carbon Steel Plate,Carbon Steel Sheet 16Mng, CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI, ASTM, GB, JIS | Grade: | Q195,Q235,Q345,A36,C45 | Thickness: | 1.0-30MM |

| Model Number: | Q235,Q195,Q345 | ||||

| Type: | Steel Plate | Technique: | Hot Rolled | Surface Treatment: | Coated |

| Application: | Ship Plate | Special Use: | Silicon Steel | Width: | 30-2000mm |

| Length: | as your requirement | standard: | hot rolled | Surface: | Anti-rust oil |

Packaging & Delivery

| Packaging Details: | seaworthy packages or as customers' require |

| Delivery Detail: | within 15 days after the advance payment |

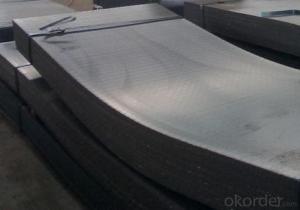

Hot rolled steel plate

1 carbon steel plate 3mm thick General information

| Product name | Type | Specification | Implementation of GB | ||

| thick | wide | long | |||

| Carbon structural steel | Q195,Q215, Q235A,Q235B, Q235C,Q255, Q275 | 4-120 | 1500-4500 | 6000-12000 | GB/T700-2006 |

| Low-alloy structural steel | Q295,Q345A, Q345B,Q2345C | 4-120 | 1500-4500 | 6000-12000 | BG/T1591-1994 |

| Quality carbon structural stee | 30-50 | 4-120 | 1500-4500 | 6000-12000 | BG/T699-1999 |

| Ship steel | CCSA,CCSB | 4-120 | 1500-4500 | 6000-12000 | materials and welding condition |

| CCSAH32,CCSAH36 CCSDH32,CCSDH36 | 4-120 | 1500-4500 | 6000-12000 | materials and welding condition or GB 712-2000 | |

| Boiler steel | 20g,22Mng, 16Mng,19Mng | 4-120 | 1500-4500 | 6000-12000 | GB 713-1997 |

| Pressure vessel steel | 1622Mng,20R, 15MnVR,15MnVNR | 4-120 | 1500-2700 | 6000-12000 | GB 6654-1996 |

| European standard plate

| S235JR,S235J0, S275JR,S275J0, S275JR2,S355JR, S355J0,S355J2 | 4-120 | 1500-4500 | 6000-12000 | EN 10025 |

| Japanese standard plate | SS400,SS400-B | 4-120 | 1500-4500 | 6000-12000 | JIS G3101-2004 |

2 carbon steel plate 3mm thick detail specification

Material:

A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D

SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235

Q195,Q235,Q345,SS400,ASTM A36,E235B

Thickness: 4mm-120mm

width: 1500mm-4500mm

Length:2-10m ,accordingly

Thickness | 4-120mm |

Width | 1500-4500mm or as custom's request |

Length | 2-12m,as your requirment |

Technique | Cold rolled or hot rolled |

Surface treatment | Bare, galvanized coated or as customer's requirements. |

Standard | ASTM,EN,GB,JIS,GB |

Material | A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235 Q195,Q235,Q345,SS400,ASTM A36,E235B |

Terms of Payment | L/C or T/T |

Chemical composition | C≤0.004%;Si≤0.030%; Mn ≤0.17%;P≤0.012%; S≤0.010%; Fe balance |

Delivery Detail | within 30days once receive deposite or confirm L/C |

Packing | Standard export packing,or as requirement |

3 carbon steel plate 3mm thick application:

construction,machinery manufacturing, container manufacturing, shipbuilding, bridge construction. Can also be used to manufacture a variety of containers, the furnace shell, furnace plate, bridge and vehicle static steel plate, low alloy steel plate,shipbuilding plate, boiler plate, pressure vessel plate, pattern plate, tractor parts, automobile frame steel plate and welding components

- Q: What are the potential drawbacks of using steel sheets?

- Some potential drawbacks of using steel sheets include their susceptibility to corrosion, their relatively high cost compared to other materials, their heaviness and difficulty in handling and transporting, and their limited flexibility and ability to be molded into complex shapes. Additionally, steel sheets may require additional maintenance and protection measures to prevent rusting and damage over time.

- Q: Can the steel sheets be cut easily?

- With the correct tools and techniques, steel sheets can be easily cut. Despite its strength and durability, steel can still be cut through methods like shearing, sawing, or by utilizing plasma or laser cutting machines. The ease of cutting steel sheets is influenced by factors such as thickness and the particular type of steel employed. Generally, thinner sheets are more manageable to cut compared to thicker ones. Moreover, employing suitable cutting tools and adhering to safety precautions will guarantee a seamless and effective cutting process.

- Q: Can steel sheets be used for walkways and platforms?

- Yes, steel sheets can be used for walkways and platforms. Steel sheets are durable, strong, and capable of supporting heavy loads, making them suitable for such applications. Additionally, they can be fabricated and designed to meet specific requirements, ensuring safety and stability for users.

- Q: Are steel sheets resistant to graffiti?

- Yes, steel sheets are generally resistant to graffiti due to their smooth and non-porous surface, making it difficult for paint and other substances to adhere. Additionally, steel sheets can be coated with anti-graffiti coatings that further enhance their resistance to graffiti.

- Q: Can steel sheets be used for outdoor sculptures or artwork?

- Yes, steel sheets can be used for outdoor sculptures or artwork. Steel is a durable material that can withstand outdoor conditions and can be shaped and welded into various artistic forms. Its strength and resistance to corrosion make it suitable for outdoor installations, allowing for the creation of long-lasting and visually appealing sculptures and artwork.

- Q: Can steel sheets be used for transportation applications?

- Transportation applications can indeed make use of steel sheets. Steel has gained immense popularity in the automotive and aerospace sectors owing to its exceptional strength, durability, and resistance to corrosion. Chassis, body panels, doors, and structural parts in various transportation components are often constructed using steel sheets. These sheets offer remarkable structural integrity and can endure substantial loads, making them ideal for vehicles and aircraft. Moreover, steel sheets can be effortlessly shaped, welded, and machined, enabling customization and efficient manufacturing procedures.

- Q: What is the difference between a standard and high-strength steel sheet?

- The main difference between a standard and high-strength steel sheet lies in their mechanical properties. High-strength steel sheets have a higher yield strength and tensile strength compared to standard steel sheets. This means that high-strength steel sheets can withstand greater forces and pressure before deformation or failure occurs. They are commonly used in applications where durability and load-bearing capacity are critical, such as in automotive and construction industries. Standard steel sheets, on the other hand, have lower strength properties but are often more cost-effective and suitable for less demanding applications.

- Q: What is the lifespan of a steel sheet?

- The lifespan of a steel sheet can vary depending on various factors such as the quality of the steel, its usage conditions, and the level of maintenance. However, on average, a steel sheet can last anywhere between 20 to 30 years.

- Q: Are steel sheets resistant to UV rays?

- Steel sheets do not possess inherent resistance to UV rays, contrary to belief. UV damage can indeed affect steel, leading to fading, discoloration, or even corrosion with the passage of time. However, the degree of harm incurred is contingent upon several factors, including the steel type, sheet thickness, UV exposure specifics, and presence of protective coatings. In order to bolster the UV resistance of steel sheets, manufacturers commonly administer coatings like paint, powder coatings, or galvanized finishes, which offer some level of defense against UV rays. It is vital to consult steel suppliers or manufacturers to ascertain the precise UV resistance capabilities of the steel sheets in use and consider supplementary protective measures if deemed necessary.

- Q: Are steel sheets suitable for agricultural applications?

- Yes, steel sheets are suitable for agricultural applications due to their durability, strength, and resistance to rust and corrosion. They can be used for various purposes in agriculture, such as constructing farm buildings, storage facilities, fencing, and equipment.

Send your message to us

Hot Rolled Carbon Steel Plate,Carbon Steel Sheet 16Mng, CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords