Galvanized Corrugated Steel Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

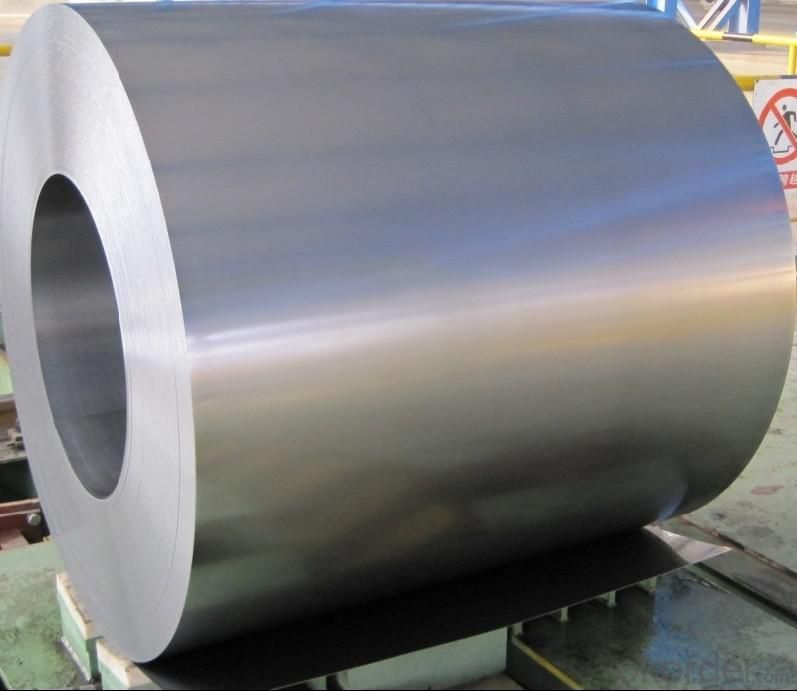

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

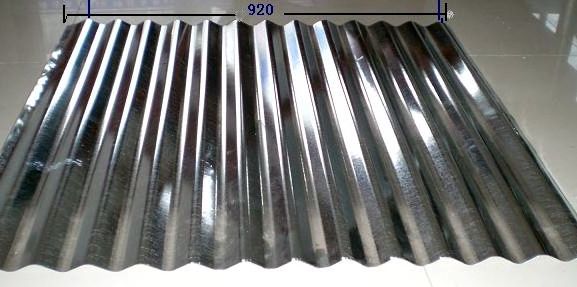

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

| Processability | Yield strength | Elongation % | Elongation % | 180°cold-bending |

| Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

| Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

| Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

| Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

| EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: How is the quality of steel sheets determined?

- Several factors and tests determine the quality of steel sheets. The chemical composition of the steel is a primary factor, including the presence and percentage of elements such as carbon, manganese, silicon, and alloying elements like chromium, nickel, and molybdenum. The specific composition impacts the steel's strength, durability, and resistance to corrosion. The mechanical properties of the steel are also important, assessed through tests like tensile strength, yield strength, elongation, hardness, and impact resistance. These tests determine the steel's ability to withstand forces and deformation without failure. Surface quality plays a crucial role as well. The surface must be defect-free, without cracks, scratches, pits, or any irregularities that could affect performance or appearance. Thickness and uniformity are crucial factors too. Thickness is measured using methods like ultrasonic gauges or micrometers to ensure compliance with specifications. Deviations from the required thickness can impact structural integrity and performance. Weldability, formability, and machinability are also tested, determining suitability for specific applications. These tests evaluate the steel's behavior during fabrication processes like welding, bending, or machining. Overall, the quality of steel sheets is determined through a comprehensive evaluation of their chemical composition, mechanical properties, surface quality, thickness, and other performance characteristics. These assessments ensure compliance with standards and suitability for intended applications.

- Q: Can steel sheets be used for manufacturing HVAC systems?

- Yes, steel sheets can be used for manufacturing HVAC systems. Steel is a common material choice due to its strength, durability, and thermal conductivity properties, making it suitable for constructing various components of HVAC systems such as ductwork, housing units, and heat exchangers.

- Q: Do the steel sheets have any specific fire ratings?

- Yes, steel sheets often have specific fire ratings due to their inherent fire-resistant properties. These ratings indicate the duration of time the steel sheet can withstand exposure to fire before it loses its structural integrity. The fire ratings are determined through rigorous testing and certification processes.

- Q: What kind of steel plate is Q234?

- Q235 is divided into four quality grades. They are Q235A, Q235B, Q235C, Q235D. The elements of iron and phosphorus in the steel increased in turn.

- Q: What is the difference between a painted and powder coated steel sheet?

- The main difference between a painted and powder coated steel sheet lies in the application process. Painted steel sheets involve applying liquid paint onto the surface, which can result in a thinner and less durable coating. On the other hand, powder coated steel sheets involve electrostatically applying dry powder onto the surface, followed by curing in an oven, resulting in a thicker and more durable coating. Powder coating also offers better resistance to chipping, scratching, and fading compared to traditional paint.

- Q: How do you join two steel sheets together?

- One common method to join two steel sheets together is welding. Welding involves melting the edges of the steel sheets and fusing them together using a welding machine and a filler metal. This creates a strong and durable bond between the two sheets. Other methods include using fasteners such as bolts, screws, or rivets, and using adhesives specifically designed for steel bonding. The choice of joining method depends on factors such as the application, desired strength, and aesthetics.

- Q: Are the steel sheets easy to install?

- Yes, steel sheets are relatively easy to install due to their lightweight nature and modular design. They can be easily maneuvered and fastened into place, making the installation process efficient and straightforward.

- Q: What is the average moisture resistance of steel sheets?

- The average moisture resistance of steel sheets can vary depending on the specific type of steel and its protective coatings. Generally, steel sheets have good moisture resistance due to their inherent corrosion resistance properties. However, the resistance can be further enhanced by applying various surface treatments such as galvanization, which adds a layer of zinc to protect against moisture and corrosion. In terms of specific values, it is difficult to provide an exact average moisture resistance without considering the specific steel grade, thickness, and coating. Typically, steel sheets with galvanized coatings can provide excellent moisture resistance, with some studies reporting corrosion rates as low as 0.1-0.5 micrometers per year in highly corrosive environments. It is crucial to note that the performance of steel sheets in resisting moisture can also be influenced by other factors such as the presence of scratches, cuts, or exposure to chemicals. Regular maintenance, inspection, and proper handling of steel sheets can help ensure their optimal moisture resistance over time.

- Q: Can steel sheets be used for wall cladding?

- Yes, steel sheets can be used for wall cladding. Steel is a durable and versatile material that can be shaped into thin sheets, making it suitable for cladding applications. It offers excellent strength, weather resistance, and can be finished with various coatings to enhance its aesthetic appeal.

- Q: Are steel sheets suitable for oil rig platforms?

- Yes, steel sheets are suitable for oil rig platforms. Steel is widely used in the construction of oil rig platforms due to its exceptional strength and durability. Oil rig platforms are subjected to harsh environmental conditions, such as extreme temperatures, high winds, and corrosive saltwater, and steel has proven to be able to withstand these conditions effectively. Steel sheets provide a strong and stable foundation for the oil rig platforms, ensuring that they can support the weight of the rig, equipment, and personnel. The high strength of steel allows for the construction of large and complex structures while maintaining stability and safety. Furthermore, steel is highly resistant to corrosion, making it an ideal material for offshore applications. The oil rig platforms are constantly exposed to saltwater, which can cause corrosion and weaken other materials. Steel sheets, however, can be specially treated with protective coatings to enhance their resistance to corrosion and extend their lifespan. In addition to its strength and corrosion resistance, steel is also a versatile material that can be easily shaped and fabricated into various components required for oil rig platforms. This flexibility allows for efficient and cost-effective construction processes, reducing both time and resources required for installation and maintenance. Overall, steel sheets are a suitable choice for oil rig platforms due to their strength, durability, corrosion resistance, and versatility. They provide a reliable and robust foundation for offshore drilling operations, ensuring the safety and longevity of the platform in challenging environments.

Send your message to us

Galvanized Corrugated Steel Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords