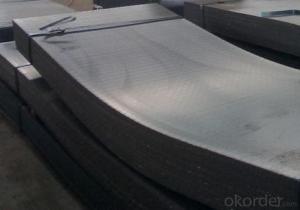

Hot Rolled Carbon Steel Plate,Carbon Steel Sheet 20Mng, CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI, ASTM, GB, JIS | Grade: | Q195,Q235,Q345,A36,C45 | Thickness: | 1.0-30MM |

| Model Number: | Q235,Q195,Q345 | ||||

| Type: | Steel Plate | Technique: | Hot Rolled | Surface Treatment: | Coated |

| Application: | Ship Plate | Special Use: | Silicon Steel | Width: | 30-2000mm |

| Length: | as your requirement | standard: | hot rolled | Surface: | Anti-rust oil |

Packaging & Delivery

| Packaging Details: | seaworthy packages or as customers' require |

| Delivery Detail: | within 15 days after the advance payment |

Hot rolled steel plate

1 carbon steel plate 3mm thick General information

| Product name | Type | Specification | Implementation of GB | ||

| thick | wide | long | |||

| Carbon structural steel | Q195,Q215, Q235A,Q235B, Q235C,Q255, Q275 | 4-120 | 1500-4500 | 6000-12000 | GB/T700-2006 |

| Low-alloy structural steel | Q295,Q345A, Q345B,Q2345C | 4-120 | 1500-4500 | 6000-12000 | BG/T1591-1994 |

| Quality carbon structural stee | 30-50 | 4-120 | 1500-4500 | 6000-12000 | BG/T699-1999 |

| Ship steel | CCSA,CCSB | 4-120 | 1500-4500 | 6000-12000 | materials and welding condition |

| CCSAH32,CCSAH36 CCSDH32,CCSDH36 | 4-120 | 1500-4500 | 6000-12000 | materials and welding condition or GB 712-2000 | |

| Boiler steel | 20g,22Mng, 16Mng,19Mng | 4-120 | 1500-4500 | 6000-12000 | GB 713-1997 |

| Pressure vessel steel | 1622Mng,20R, 15MnVR,15MnVNR | 4-120 | 1500-2700 | 6000-12000 | GB 6654-1996 |

| European standard plate

| S235JR,S235J0, S275JR,S275J0, S275JR2,S355JR, S355J0,S355J2 | 4-120 | 1500-4500 | 6000-12000 | EN 10025 |

| Japanese standard plate | SS400,SS400-B | 4-120 | 1500-4500 | 6000-12000 | JIS G3101-2004 |

2 carbon steel plate 3mm thick detail specification

Material:

A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D

SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235

Q195,Q235,Q345,SS400,ASTM A36,E235B

Thickness: 4mm-120mm

width: 1500mm-4500mm

Length:2-10m ,accordingly

Thickness | 4-120mm |

Width | 1500-4500mm or as custom's request |

Length | 2-12m,as your requirment |

Technique | Cold rolled or hot rolled |

Surface treatment | Bare, galvanized coated or as customer's requirements. |

Standard | ASTM,EN,GB,JIS,GB |

Material | A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235 Q195,Q235,Q345,SS400,ASTM A36,E235B |

Terms of Payment | L/C or T/T |

Chemical composition | C≤0.004%;Si≤0.030%; Mn ≤0.17%;P≤0.012%; S≤0.010%; Fe balance |

Delivery Detail | within 30days once receive deposite or confirm L/C |

Packing | Standard export packing,or as requirement |

3 carbon steel plate 3mm thick application:

construction,machinery manufacturing, container manufacturing, shipbuilding, bridge construction. Can also be used to manufacture a variety of containers, the furnace shell, furnace plate, bridge and vehicle static steel plate, low alloy steel plate,shipbuilding plate, boiler plate, pressure vessel plate, pattern plate, tractor parts, automobile frame steel plate and welding components

- Q: What is the average weight of a steel sheet?

- The average weight of a steel sheet can vary depending on its dimensions and thickness.

- Q: Can steel sheets be used for water tanks or storage containers?

- Yes, steel sheets can be used for water tanks or storage containers. Steel is a durable and strong material that is often used in construction and manufacturing industries. It is resistant to corrosion and leakage, making it an ideal choice for holding and storing water or other substances. Additionally, steel sheets can be easily fabricated and assembled into various shapes and sizes to meet specific requirements for water tanks or storage containers.

- Q: Are steel sheets suitable for HVAC systems?

- Yes, steel sheets are suitable for HVAC systems. Steel sheets are commonly used in HVAC systems due to their durability, strength, and resistance to corrosion. They provide structural integrity to the system and can withstand high temperatures and pressure. Additionally, steel sheets are easy to fabricate and can be customized to fit specific HVAC system requirements. They are also cost-effective and have a long lifespan, making them a preferred choice for HVAC system components such as ductwork, ventilation systems, and air handling units.

- Q: What are the standard dimensions for steel sheets?

- The standard dimensions for steel sheets vary depending on the specific type and grade of steel, but commonly used dimensions include 4 feet by 8 feet, 4 feet by 10 feet, and 5 feet by 10 feet.

- Q: What are the different edge treatments available for steel sheets?

- Some common edge treatments available for steel sheets include sheared edges, deburred edges, rolled edges, chamfered edges, and beveled edges.

- Q: What are the standard sizes of steel sheets?

- The standard sizes of steel sheets can vary depending on the type and purpose, but some common dimensions include 4 feet by 8 feet, 5 feet by 10 feet, and 6 feet by 20 feet.

- Q: Can steel sheets be used for making kitchen appliances?

- Yes, steel sheets can be used for making kitchen appliances. Steel is a popular choice for kitchen appliances due to its durability, strength, and resistance to corrosion. Stainless steel sheets are commonly used in the production of kitchen appliances like refrigerators, ovens, stoves, dishwashers, and range hoods. The smooth surface of steel sheets is easy to clean and maintain, making it ideal for kitchen applications. Additionally, steel sheets can be shaped and formed into various designs, allowing manufacturers to create sleek and modern-looking appliances.

- Q: Are the steel sheets suitable for architectural cladding?

- Steel sheets are indeed appropriate for architectural cladding. Steel, being a sturdy and long-lasting substance, offers outstanding defense against weather conditions and external influences. It is easily malleable and can be crafted into diverse shapes, making it extremely adaptable for architectural purposes. Moreover, steel cladding provides a contemporary and polished appearance, permitting the creation of visually captivating building exteriors. Additionally, steel sheets can be coated or painted to augment their ability to resist corrosion and to further personalize their look. All in all, due to their strength, durability, versatility, and aesthetic allure, steel sheets are widely favored for architectural cladding.

- Q: Are steel sheets suitable for HVAC equipment?

- Yes, steel sheets are suitable for HVAC equipment. Steel is a durable and strong material that can withstand the demanding conditions of HVAC systems, such as high temperatures and corrosion. It is commonly used for ductwork, air handling units, and other HVAC components due to its excellent mechanical properties and resistance to wear and tear.

- Q: What are the different thickness options for steel sheets?

- The thickness options for steel sheets vary depending on the specific application and industry requirements. Common thickness options for steel sheets range from thin gauges, such as 26 gauge (0.0179 inches) or 30 gauge (0.0120 inches), to thicker gauges, such as 16 gauge (0.0598 inches) or 10 gauge (0.1345 inches). However, it is important to note that steel sheets can be customized to meet specific thickness requirements beyond these standard options.

Send your message to us

Hot Rolled Carbon Steel Plate,Carbon Steel Sheet 20Mng, CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords