Hot-dip Galvanized Steel Sheet/Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

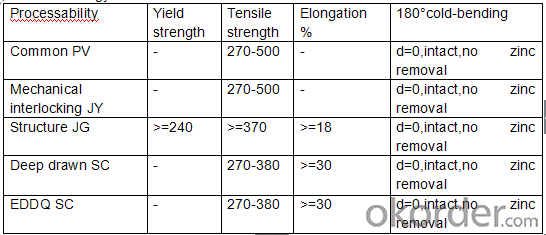

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What is the typical electrical conductivity of a steel sheet?

- The typical electrical conductivity of a steel sheet is relatively low compared to other metals. Steel is considered to be a poor conductor of electricity, with a conductivity ranging from 6.99 to 9.71 million siemens per meter (MS/m), depending on the specific type and composition of the steel.

- Q: Are steel sheets prone to warping or bending over time?

- In general, warping or bending over time is not a common issue with steel sheets. Steel is renowned for its exceptional strength and durability, making it less prone to deformation compared to alternative materials. It is worth noting, however, that the thickness and quality of the steel sheet can impact its susceptibility to warping or bending. Thicker and higher-quality steel sheets have a lower likelihood of warping or bending. Furthermore, implementing appropriate installation and maintenance techniques can also help prevent warping or bending of steel sheets. All in all, steel sheets are widely regarded as a dependable and steadfast material that maintains its shape and integrity throughout time.

- Q: What are the different profile options available for steel sheets?

- Steel sheets come in various profile options, each serving distinct purposes and offering unique advantages. Some commonly used profiles are: 1. Plain Sheet: This is the most basic option with a flat surface and no additional features. It is commonly employed for general purposes where aesthetics are not a priority. 2. Corrugated Sheet: These sheets have parallel ridges and grooves, forming a wavy pattern. They provide extra strength and rigidity, making them ideal for roofing, cladding, and fencing. The ridges also facilitate water shedding, preventing water accumulation. 3. Ribbed Sheet: Ribbed sheets have raised parallel ridges or ribs along their length. This profile offers enhanced strength and load-bearing capacity, making it suitable for applications requiring structural integrity, like mezzanine floors, decking, and industrial flooring. 4. Perforated Sheet: Perforated sheets have a pattern of punched holes, allowing for ventilation, light transmission, and drainage. They are commonly used in architectural designs, façades, acoustics, and filtration systems. 5. Tread Plate: Tread plates have an embossed pattern of lines or diamonds on the surface. This profile provides extra grip and slip resistance, making it ideal for industrial flooring, stairs, ramps, and walkways. 6. Expanded Metal: Expanded metal sheets are created by cutting and stretching a flat sheet, resulting in diamond-shaped openings. This profile offers excellent ventilation, visibility, and security, making it suitable for grilles, screens, fences, and enclosures. 7. Lipped Sheet: Lipped steel sheets have an edge or lip bent at a 90-degree angle along one or more sides. This profile provides added strength and stiffness, commonly used for framing, shelving, and edge protection. These are just a few examples of the available profile options for steel sheets. The choice of profile depends on specific requirements such as strength, durability, aesthetics, and functionality.

- Q: Are steel sheets prone to warping or distortion?

- Yes, steel sheets are prone to warping or distortion due to various factors such as heat, pressure, or inadequate cooling methods during manufacturing processes.

- Q: How are steel sheets measured?

- Steel sheets are typically measured by their thickness, width, and length. The thickness is expressed in gauge or millimeters, while the width and length are measured in feet or meters.

- Q: Are the steel sheets suitable for electrical applications?

- Yes, steel sheets are suitable for electrical applications as they have good conductivity and can be easily shaped into desired forms for various electrical components.

- Q: Can steel sheets be used for electrical conductivity applications?

- No, steel sheets are not typically used for electrical conductivity applications. While steel is a good conductor of heat and has some electrical conductivity, it is not as efficient as other materials specifically designed for electrical conductivity, such as copper or aluminum. Steel sheets are commonly used in applications where strength, durability, and corrosion resistance are important, such as construction, automotive manufacturing, and industrial equipment. For electrical conductivity applications, it is more common to use materials with higher conductivity, such as copper or aluminum. These materials have lower resistance and are better suited for conducting electricity efficiently.

- Q: How are steel sheets cleaned and maintained?

- There are various methods available for cleaning and maintaining steel sheets, depending on specific requirements and conditions. Below are some commonly used approaches: 1. Regular cleaning: It is important to clean steel sheets regularly to eliminate dust, dirt, and other debris that may accumulate on the surface. This can be accomplished by using a soft cloth or sponge along with mild soap or detergent and warm water. It is advisable to avoid abrasive cleaners or scrub brushes that can cause surface scratches. 2. Rust removal: Prompt removal of rust spots is crucial to prevent further corrosion on steel sheets. Rust can be eliminated using a wire brush, sandpaper, or a rust remover solution. Once removed, the area should be thoroughly cleaned and dried. 3. Protective coating: Applying a protective coating can help prevent rust and corrosion, especially for steel sheets exposed to harsh environments or moisture. Coating options include paint, varnish, or specialized anti-corrosion coatings. The coating should be applied in accordance with the manufacturer's instructions and reapplied periodically as needed. 4. Proper storage: To prevent moisture buildup and corrosion, it is important to store steel sheets in a dry and well-ventilated area. They should be kept away from direct contact with the ground and other metals to avoid galvanic corrosion. Additionally, using covers or protective wraps can provide further protection against dust and other contaminants. 5. Periodic inspection: Regularly inspecting steel sheets for any signs of damage, such as dents, scratches, or cracks, is essential. If any damage is identified, it should be promptly repaired to prevent further deterioration. 6. Professional maintenance: In the case of large-scale or complex steel sheet installations, it may be necessary to enlist professional maintenance services. These experts possess the knowledge, tools, and experience required to perform more extensive cleaning, maintenance, and repairs. By adhering to these cleaning and maintenance practices, steel sheets can maintain their integrity, appearance, and performance over time.

- Q: What is the difference between hot dipped galvanized and electro galvanized steel sheets?

- Galvanized steel sheets can be categorized into two types: hot dipped galvanized and electro galvanized. These two types differ in how they are applied and the resulting characteristics of the coating. Hot dipped galvanized steel sheets are made by immersing the steel into a bath of molten zinc. This process creates a thick and durable coating that effectively prevents corrosion. The zinc completely covers the surface and edges of the steel, ensuring comprehensive protection against rust and other forms of degradation. The thickness of the coating can be adjusted based on the specific application and level of protection required. On the other hand, electro galvanized steel sheets are produced through electroplating the steel with a thin layer of zinc. First, the steel is cleaned and treated with an acid solution to remove impurities and enhance adhesion. Then, it is submerged in a solution of zinc electrolyte, and an electric current is applied to the bath. This causes the zinc ions to bond with the surface of the steel. As a result, the coating formed is much thinner compared to hot dipped galvanized steel. Due to the thinner coating, electro galvanized steel sheets offer less resistance to corrosion compared to their hot dipped counterparts. They are more suitable for indoor applications or environments with less exposure to harsh conditions. However, electro galvanized steel sheets have their own advantages, such as a smoother and more uniform appearance. This makes them a popular choice for applications where aesthetics play a significant role, such as automotive parts or appliances. In conclusion, the primary distinction between hot dipped galvanized and electro galvanized steel sheets lies in their application method and the resulting thickness of the coating. Hot dipped galvanized steel sheets have a thicker and more durable coating, providing superior protection against corrosion. On the other hand, electro galvanized steel sheets have a thinner coating, making them more suitable for indoor applications and offering a smoother appearance.

- Q: What is the difference between hot-rolled and cold-rolled steel sheets?

- The main difference between hot-rolled and cold-rolled steel sheets lies in their production process. Hot-rolled steel sheets are made by heating the steel above its recrystallization temperature and then rolling it into its final shape, resulting in a rougher surface texture. On the other hand, cold-rolled steel sheets are processed at room temperature, which allows for tighter control over the dimensions and a smoother surface finish. Cold-rolled steel sheets also tend to have higher strength and better formability compared to hot-rolled sheets.

Send your message to us

Hot-dip Galvanized Steel Sheet/Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords