Home Depot Armstrong Ceiling Grid - Suspension Ceiling Grid System w Angle of Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 150000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Flat Suspension Grids) Description

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

2,Main Features of the (Flat Suspension Grids)

Shape:Plane,groove

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized steel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic cold roll forming and punching machineries guarantee the high precision.

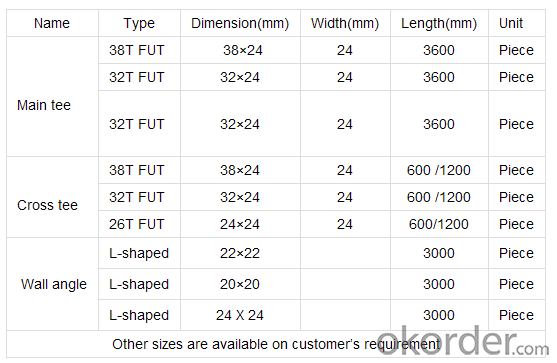

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

3,(Flat Suspension Grids) Images

4,(Flat Suspension Grids) Specification

5,FAQ of (Flat Suspension Grids)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

4. Can be installed according to practical demands.

5. The physical coefficient of all kinds Suspension

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

- Q: Code for construction of light steel keel gypsum board ceiling in decoration works

- 1) plate should be fixed in the free state to prevent the emergence of bending, convex drum phenomenon. 2) The long side of the gypsum board (ie, the wrapping edge) shall be laid in the longitudinal keel. 3) tapping screw and gypsum board edge distance: package edge to 10 ~ 15 mm is appropriate, cutting the board to 15 ~ 20 mm is appropriate. 4) fixed gypsum board sub-keel spacing should not be greater than 600 mm, our company uses 400 mm. 5) nail distance to 150 ~ 170 mm is appropriate, the screw should be perpendicular to the board. Bending, deformation of the screws should be removed, and in the 50 mm apart the other parts of the screw. 6) gypsum board seams should be properly handled by the manager of the organization of professional workers to seriously study to take strict anti-cracking measures. 7) gypsum board and keel fixed, should be from the middle of a plate to the four sides of the plate fixed, not at the same time operations. 8) screw head should be slightly embedded in the board, does not make the board surface damage, nail should be used for rust treatment and plaster putty smooth. 9) Mix the plaster putty, you must use clean water and clean the container. 4, finished product protection: ceiling decoration after installation, not free to chisel, is strictly prohibited from the upper and lower damage ceiling lamps, tuberculosis, etc. shall not be damaged and polluted ceiling; follow-up operation, should take protective measures to prevent pollution. 5, down the ceiling construction, on the ground open line ink positioning, and then hang hanging hanging out of the hanging shape of the exact location. Install the lifting of the support boom, test hanging after the temporary suspension, after leveling line, and then cut the shape of fastening. Used wood side, plywood should be carried out fire, pest control.

- Q: Light steel keel d60 and u60 What is the difference?

- D60 may be the ceiling 60 bearing keel specifications: DC60 * 27 * 1.2, may also be the ceiling 60 cover keel specifications: DC60 * 27 * 0.6 U refers to the keel shape shape, the general ceiling 38 carrying keel and ceiling 50 bearing keel are U-shaped, but the ceiling 60 bearing keel should be C-type, the general manufacturers do not strictly according to the standard to put 60 bearing keel is also promoted to U Type became U60

- Q: I have a little package to do their own works, only the contractor does not material, people give the price is 13 dollars a square, but also put noise cotton, in general, that the calculation area is to be considered double or single of,

- I also do decoration, in general, the calculation area is single-sided, the paint is double-sided operator, this is not absolute, the key is how the contract on the set! 13 of the price is too low, the project is rarely the case of 20 to a flat (artificial)!

- Q: Construction Technology of Silicon and Caelite Ceiling in Light Steel

- Calcium silicate board ceiling is the main advantage of light, waterproof, sound absorption, construction is simple. 1) Material requirements Calcium silicate board specifications, performance indicators meet the design and the corresponding acceptance requirements. The keel, boom and fittings required for the ceiling meet the requirements of the design and catalog specifications. 2) The main construction tools Electric saw, no tooth saw, nail gun, hand saw, hand plane, pliers, screwdriver, wrench, square feet, steel ruler, steel tape and so on. 3) construction conditions and related environment around the wall playing a good roof + 50cm level elevation control line, and verification is completed. ?Install the roof of the various lines and ventilation ducts, to determine the light, ventilation and a variety of exposed Ming mouth position. And check the height of the ceiling and its equipment within the impact of elevation. ?Check whether the materials and fittings used are well prepared. Before the keel, you must complete the wet work on the wall surface. Erected a roof construction platform. Calcium silicate board keel ceiling in a large area before the construction, should do the model, the ceiling from the crown, lamp trough, vents of the tectonic treatment, block and fixed method should be tested and identified after a large area construction.

- Q: I'm getting a new room in my house, and I really want to do a mosaic on the ceiling. I love everything artistic so I'd want to do it myself, and I know it's going to take a long time to do a room that's 18 ft by 22 ft, but I really want to. I've actually never done mosaics before and I'm aware that they are difficult to do and that this is a monumental project for someone who has never even done a mosaic before. But I wanted to know the easiest possible way to go about it (because the idea of standing on a ladder the entire time does not appeal to me whatsoever)? Like, could I do the mosaic on another surface and then attach it to my ceiling? or I don't know, please help me.

- Monumental doesn't even came close. To make it realistic you will need to do it on the ceiling, otherwise it will look like patchwork. First thing is to design on paper what you want it to look like. Then transfer design to grid paper. No stepladder. Buy a scaffold that is big enough and high enough to lie on. Transfer your design to the ceiling. You can make stencils for this, and use multiple chalk lines to keep everything straight. Before you start, practice on a plywood board. When you buy your materials, make sure you tell the salesman you are doing a ceiling so you get the right cement or mastic. It took Michelangelo 7 years to do the Sistine Chapel, and he used paint. Good Luck!

- Q: Light steel keel main keel, vice keel spacing generally how much

- The main keel and pay keel ceiling is this: the main keel and the main keel parallel row, the spacing of 1200mm,

- Q: How can we calculate the cost of paint keel?

- Keel surface area, (long by wide + long by high + wide by high) by 2 Asked: This is the cost of the formula? Answer: This is the keel surface area, calculate the area need to use a few paint on it. Or with a specified amount of paint, to see how many root keel can be painted, can be.

- Q: Light steel keel wall need to do wall

- Um, what does that mean? Specifically, it is clear?

- Q: Light steel keel use method

- Commonly used wall steel keel specifications are 75mm and 100mm, the length of 3m and 4m; ceiling with 2, the installation of light outlet according to the size of the weight to determine the fixed method, according to the design of the construction. 3, keel

- Q: I'm in the process of finishing my basement and only have the ceiling left to complete. I used metal studs for the framing and am using a metal grid system for a drop ceiling. How should I attach the wall molding to the walls? The manufacturer says to use nails, but that's obviously not an option with the metal studs. Would a drywall screw meant for metal framing work?

- I would use a modified truss screw. It has a good grip thread and a flat bearing surface to the head to help support the thin metal. An added advantage is that the head is thin and won't interfere as much with objects sliding over them, like ceiling tiles. Haven't had any luck finding them at place like The Home Depot, but most lumber yards carry them.

Send your message to us

Home Depot Armstrong Ceiling Grid - Suspension Ceiling Grid System w Angle of Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 150000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords