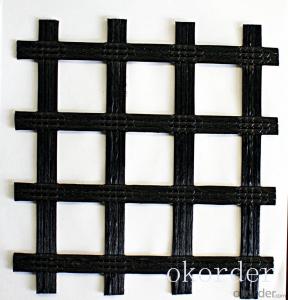

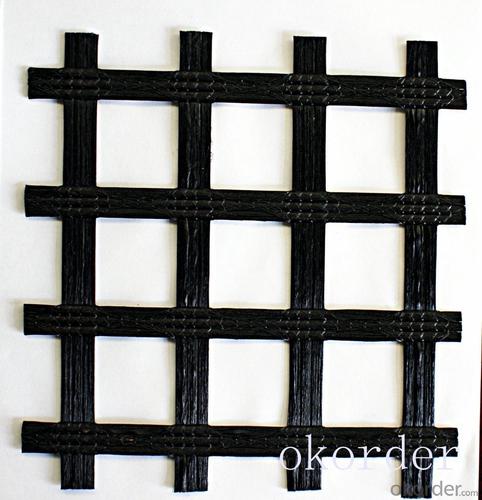

High Tensile Strength Fiberglass Geogrids Price Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geogrids

Place of Origin:

Anhui, China (Mainland)

Brand Name:

CMAX

Model Number:

Biaxial

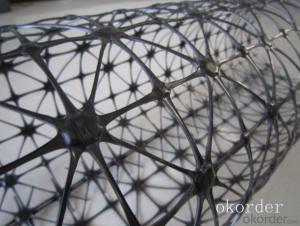

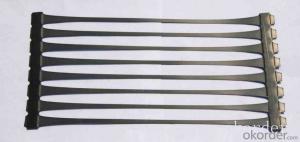

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is composed of fiberglass filaments that are coated with an inorganic sizing agent

Geogrid protects channel slopes, provides resistance and stability, protecting this object from erosion. Additional advantage is drainage along channels. Geogrid application considerably reduces losses, connected with fall of ground, landslides and deformation of slopes.Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the advantages of using geogrids in construction projects?

- Geogrids offer several advantages in construction projects. Firstly, they enhance the stability and strength of the soil by distributing loads and reinforcing the ground. This helps in the construction of structures on weak or unstable soil conditions. Secondly, geogrids improve the longevity of infrastructure by reducing soil erosion and preventing soil settlement. They also provide better load distribution, reducing the need for excessive excavation and backfilling. Additionally, geogrids are cost-effective as they require less material and labor compared to traditional construction methods. Overall, using geogrids in construction projects can result in improved structural integrity, increased durability, and cost savings.

- Q: What are the factors that affect the performance of geogrids under cyclic loading?

- There are several factors that can affect the performance of geogrids under cyclic loading. These include the type and quality of the geogrid material, the design and installation of the geogrid, the magnitude and frequency of the cyclic loading, the properties of the surrounding soil, and the environmental conditions. Additionally, factors such as aging, degradation, and maintenance of the geogrid can also impact its performance under cyclic loading.

- Q: Are geogrids suitable for use in high water table areas?

- Yes, geogrids are suitable for use in high water table areas. Geogrids are designed to reinforce soil and provide stability, making them a suitable solution for areas with high water tables where soil erosion and instability can be common. Their high tensile strength and ability to distribute loads make them effective in preventing soil movement and maintaining long-term stability in such areas.

- Q: What is the typical thickness of a geogrid?

- The typical thickness of a geogrid can vary depending on the specific application and manufacturer. However, most geogrids range in thickness from 0.5 to 3 millimeters.

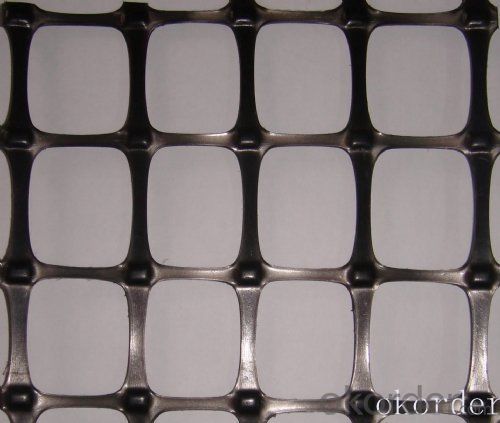

- Q: What are the types of Geogrid

- Glass fiber geogrid, 1595341 polyester fiber geogrid, glass fiber, polyester composite geotextile, steel plastic composite geogrid, PP grid, one-way two-way stretching plastic geogrid,

- Q: What is the typical geogrid roll length for specific applications?

- The typical geogrid roll length for specific applications can vary depending on the project requirements and the specific type of geogrid being used. However, common geogrid roll lengths range from 50 to 500 feet, with some specialty products available in longer lengths.

- Q: Are geogrids resistant to microbial attack?

- Yes, geogrids are generally resistant to microbial attack. Their construction materials, such as polyester or polypropylene, are not easily degraded by microorganisms, making geogrids a durable and long-lasting solution in various applications.

- Q: Can geogrids be used in reinforcement of embankments on expansive clays?

- Yes, geogrids can be used in the reinforcement of embankments on expansive clays. Geogrids are commonly used in such scenarios to improve the stability and performance of embankments by providing tensile strength and preventing soil movement. By distributing the load and reducing the potential for settlement, geogrids effectively reinforce embankments on expansive clays.

- Q: How do geogrids improve the performance of reinforced slopes?

- Geogrids improve the performance of reinforced slopes by providing additional stability and strength to the soil structure. They act as a reinforcement material, increasing the tensile strength of the soil and preventing it from sliding or collapsing. The geogrids also distribute the applied loads more evenly, reducing the potential for deformation and settlement. Overall, geogrids enhance the slope's resistance to erosion, improve slope stability, and increase the longevity and durability of the reinforced structure.

- Q: Geogrid construction must be folded back 2m wrapped in compacted packing

- Geogrid in flat lower bearing layer according to design requirements of the laying of the width, lower filler unarmed bad geogrid debris, geogrid, the high strength in the direction perpendicular to the axial direction of embankment layout, geogrid transverse laying, laying taut, stretched, and avoid wrinkle twist or potholes, geogrid along the longitudinal splicing by overlapping method, lap width not less than 20cm.

Send your message to us

High Tensile Strength Fiberglass Geogrids Price Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords