Geo Cells and Geogrids - Bitumen Coated Fiberglass Geogrid with Certification

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

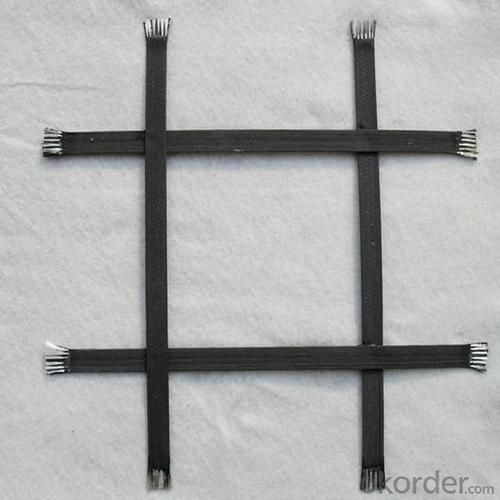

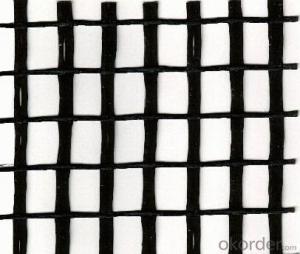

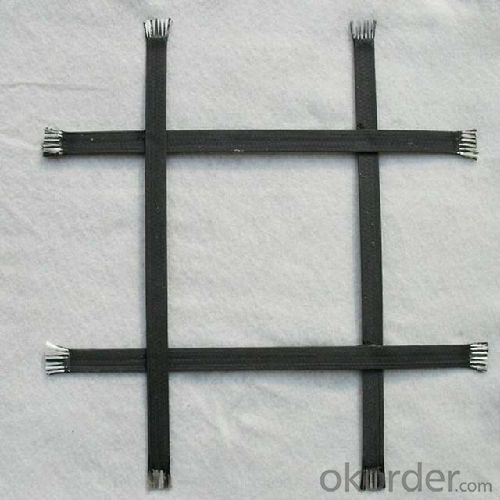

Fiberglass Geogrid Introduction

Fiberglass geogrid is a new excellent maeterial used for reinforcing road surface and base, it made by fiberglass filament, and covered by special solution. High longitudinal and horizontal strength, low elongation rate, anti-alkali and aging resistance, widely used in asphalt road surface, concrete road surface and reinforceing road base.

Main Feature of Fiberglass Geogrid

1.Tensile Strength (KN/m):

30X30KN/M,50x50KN/M,60X60KN/M,70X70KN/M,80X80KN/M

2. Elongation: 3%

3. Mesh Size: 25.4 x 25.4mm or 12.7x 12.7mm

4. Width: 1-6m

5.Temperature Resistance (Centigrade) : -100~290

6.Surface Processing: Modified asphalt or Polymer and self adhesive

7.Packing: with PE bag packing

Also detailed specification may be manufacturered according to your need.

if you are interest in our project, pleas contact me for further information.

Detail Specifications of Fiberglass Geogrid

Specification | 1×1 | 1×1 | 1×1 | 1×1 | 1×1 | 2×2 | 2×2 | |

Strength | Long . Horiz | ≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥60 | ≥80 |

≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥60 | ≥80 | ||

Percentage of Elongation | 4% | 4% | 4% | 4% | 4% | 4% | 4% | |

Size of Hole mm | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 12.7×12.7 | 12.7×12.7 | |

Flexibility | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width M | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 | 1--6 | |

Temperature | -100200 | -100200 | -100200 | -100200 | -100200 | -100200 | -100200 | |

FAQ

1. What's the usage of geogrid?

It's used for reinforce the roadbeds in softe soil, railway and dam etc. It has good performance on preventing the cracks.

2. How about your quality of geogrid?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

- Q: Especially in the curtain wall project

- Know that the grille here is to prevent "reflective cracking" and improve the shear capacity

- Q: Can geogrids be used in underwater applications?

- Yes, geogrids can be used in underwater applications. They are commonly used to stabilize the soil and prevent erosion in underwater environments such as riverbanks, coastlines, and underwater pipelines. Geogrids provide strength and stability to the soil, allowing it to withstand the forces of water currents and waves.

- Q: I would like to ask the Lebanon warp knitting machine, the model is: Cop - HS_2ST geogrid do know how to process

- The geogrid is mainly composed of plastic geogrid, fiberglass geogrid, steel plastic geogrid, polyester geogrid. The plastic geogrid has a one-way plastic geogrid and a two-way plastic geogrid.

- Q: Can geogrids be used in temporary construction access mats?

- Yes, geogrids can be used in temporary construction access mats. Geogrids are commonly used to improve the stability and load-bearing capacity of access mats, making them suitable for temporary construction sites. They help distribute the weight of heavy equipment and vehicles and prevent soil erosion, ensuring safe and efficient access for construction activities.

- Q: The difference between composite geomembrane and bentonite waterproof blanket

- The products of different materials, bentonite waterproof blanket composed of clay minerals and natural material processing machine, high expansibility and high water absorption capacity, moisture permeability is low; the composite geomembrane material is polyethylene particles by calendering equipment to produce plastic film

- Q: Are geogrids suitable for use in mechanically stabilized bridge abutments?

- Yes, geogrids are suitable for use in mechanically stabilized bridge abutments. Geogrids provide reinforcement and stability to the soil behind the abutments, preventing lateral movement and potential failure. They are highly effective in enhancing the load-bearing capacity and durability of bridge abutments, making them a reliable and commonly used solution in civil engineering projects.

- Q: What are the differences between geogrids and geocells?

- Geogrids and geocells are both materials used for soil reinforcement and stabilization, but they have distinct differences. Geogrids are typically made of high-strength synthetic materials such as polyester or polypropylene, and they are formed into a grid-like structure. They provide tensile strength to soil, preventing lateral movement and improving load distribution. On the other hand, geocells are three-dimensional cellular structures made from materials like high-density polyethylene. They create a honeycomb-like network that confines soil particles, preventing erosion and promoting load-bearing capacity. While geogrids are commonly used for soil stabilization in applications like road construction, geocells are often employed for erosion control and slope stabilization.

- Q: How do geogrids improve the performance of paved and unpaved roads?

- Geogrids improve the performance of paved and unpaved roads by providing reinforcement and stabilization to the soil or aggregate layers. They distribute the load from traffic more evenly, reducing stress and preventing rutting or deformation. Geogrids also enhance the tensile strength of the road, improving its resistance to cracking and extending its lifespan. Additionally, they help in reducing the amount of materials needed for construction, making the roads more cost-effective and environmentally friendly.

- Q: Are geogrids suitable for use in slope reinforcement during excavation?

- Yes, geogrids are suitable for use in slope reinforcement during excavation. Geogrids provide stability and reinforcement to slopes by distributing the load and preventing soil erosion. They are effective in strengthening the slope, reducing the risk of landslides, and improving overall safety during excavation operations.

- Q: Can geogrids be used in reinforcement of underground storage tanks?

- Yes, geogrids can be used in the reinforcement of underground storage tanks. Geogrids provide additional stability and strength to the tank's structure, preventing soil and groundwater pressures from causing deformation or collapse. By reinforcing the surrounding soil, geogrids ensure the tank's integrity and longevity.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | 20.00% North America 15.00% South America 15.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 80,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Geo Cells and Geogrids - Bitumen Coated Fiberglass Geogrid with Certification

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords