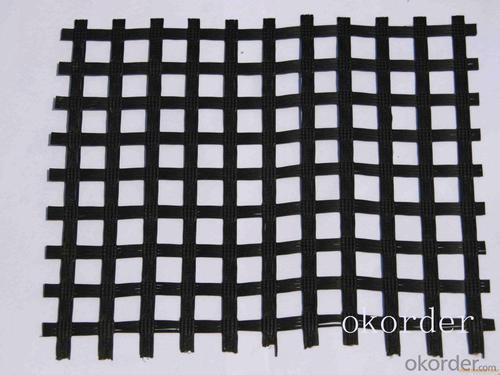

Hanes High Strength Fiberglass Geogrids for Civil Engineering Construction - Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

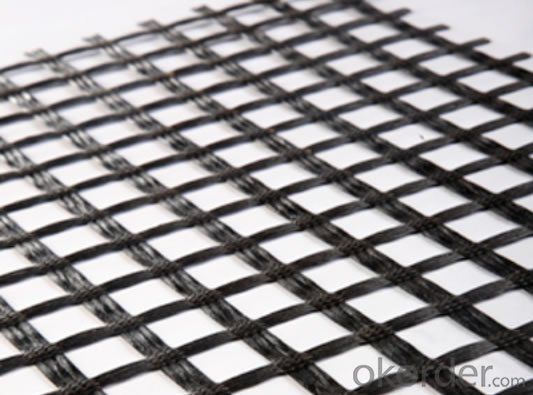

Plastic Geogrid is drilling a hole in the polymer board, by cold-drawn, the shape with large holes(long hole or square hole) of the high strength reinforcement material. According to customer demand, could composite geotextile or other material.

CNBM offers BaseGrid biaxial geogrids for base reinforcement. They are manufactured by welding or stitching together two layers of extruded, polypropylene, flexible geogrids to create a continuous sheet that will not separate.

Main applications:

Road bed reinforcement-it can effectively allocate and disperse load,improve the stability and load capacity of road bed and extend the useful lfe of road

It can be withstand greater alternating load

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geogrids be used in pond liners?

- Yes, geogrids can be used in pond liners. Geogrids are often used as a reinforcement material in the construction of pond liners to enhance their stability, prevent soil erosion, and increase their overall strength and durability.

- Q: What are the factors that affect the design and selection of geogrids for geosynthetic reinforcement of slopes?

- There are several factors that affect the design and selection of geogrids for geosynthetic reinforcement of slopes. These factors include the slope angle, soil type and properties, anticipated loads and stresses, construction constraints, and environmental conditions. The slope angle determines the required strength and stiffness of the geogrid to resist gravitational forces and prevent slope failure. The soil type and properties, such as cohesion and internal friction angle, influence the interaction between the geogrid and the soil, affecting the required geogrid aperture size and tensile strength. The anticipated loads and stresses, such as traffic loads or groundwater pressures, determine the design strength and durability requirements of the geogrid. Construction constraints, such as access limitations or equipment availability, may influence the selection of geogrid installation methods. Lastly, environmental conditions, such as temperature variations or chemical exposure, affect the long-term performance and durability of the geogrid, influencing the choice of materials and protective measures. Overall, a thorough understanding of these factors is essential for the effective design and selection of geogrids for geosynthetic reinforcement of slopes.

- Q: Geosynthetic materials for flood control materials

- The aging rate of geotextile exposed to sunlight is very fast, which can only be used for 1 years at most. However, the aging speed will be much slower when buried in soil or under water. At present, the aging speed of polypropylene fabric is very fast, the aging rate of polyester and polyethylene fabric is slow, and the difference is nearly L times. For the same kind of geosynthetics, light aging fast, slow aging aging dark, flat, thin, round wire, thick slow aging. Geomembrane is generally divided into two categories of asphalt and polymer. Each of the two classes has no reinforcement and reinforcement. The most commonly used polymer geomembrane is PVC, CPE, CB, HDPE, CSPE, etc..

- Q: What are the factors that affect the cost-effectiveness of geogrids?

- The factors that affect the cost-effectiveness of geogrids include the quality and strength of the geogrid material, the size and complexity of the project, the type of soil being reinforced, the installation method, and the long-term performance and durability of the geogrid. Additionally, factors such as transportation and logistics costs, project timeline, and the availability of alternative solutions can also influence the overall cost-effectiveness of geogrids.

- Q: What are the benefits of using geogrids in roadways?

- The benefits of using geogrids in roadways include improved load-bearing capacity, reduced pavement thickness, increased stability and durability, prevention of cracking and rutting, enhanced drainage and erosion control, and cost savings in construction and maintenance.

- Q: What is the typical width of a geogrid roll?

- The typical width of a geogrid roll is usually around 4 to 6 feet.

- Q: How do geogrids improve the performance of reinforced soil slopes in seismic areas?

- Geogrids improve the performance of reinforced soil slopes in seismic areas by providing stability and reinforcement to the soil structure. They enhance the tensile strength of the soil and distribute the applied loads more evenly, reducing the potential for slope failure during seismic events. Additionally, geogrids help to control soil erosion and prevent soil displacement, resulting in improved overall slope stability and resilience in seismic areas.

- Q: What is the difference between geogrids and geotextiles?

- Geogrids and geotextiles are both used in civil engineering and construction projects, but they have distinct differences in their design and function. Geogrids are typically made of high-strength polymer materials and have a grid-like structure, often resembling a net or mesh. They are primarily used to reinforce soil and provide stability to structures by distributing loads and reducing soil movement. Geogrids are commonly used in applications such as road and pavement construction, retaining walls, and slope stabilization. On the other hand, geotextiles are permeable fabrics made from synthetic fibers. They are designed to filter, separate, reinforce, or protect soil and other materials. Geotextiles can be woven or non-woven and are used for various purposes, including erosion control, drainage systems, filtration, and soil stabilization. They are often used in applications such as landscaping, erosion control blankets, and landfills. In summary, the main difference between geogrids and geotextiles lies in their structure and main function. Geogrids provide reinforcement and stability to soil and structures, while geotextiles are used for filtration, separation, and protection purposes.

- Q: What are the factors that affect the installation and survivability of geogrids in cold climates?

- The factors that affect the installation and survivability of geogrids in cold climates include the type and quality of geogrid material, proper preparation of the subgrade, adequate compaction of the soil, temperature variations, frost heave, snow accumulation, and freeze-thaw cycles.

- Q: Can geogrids be used in mining and landfill applications?

- Yes, geogrids can be used in mining and landfill applications. Geogrids are commonly used in these industries to reinforce soil and provide stability. They help in preventing soil erosion, improving load-bearing capacity, and enhancing overall safety and efficiency in mining and landfill operations.

Send your message to us

Hanes High Strength Fiberglass Geogrids for Civil Engineering Construction - Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords