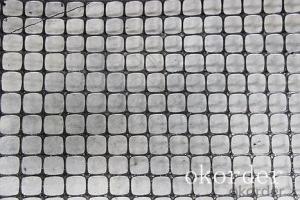

Ground Stabilisation Geogrids - High Modulus Fiberglass Geogrid with High Tensile Strength Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geogrids

Place of Origin:

Anhui, China (Mainland)

Brand Name:

CMAX

Model Number:

Biaxial

Production function

1.It can be applied in all kinds of roads,airports to enhance the roadbed;

2.It can be applied in a large car park and terminal freight yard,etc. to strengthen the foundations of a permanent load;

3.It can be applied in rail, road slope's protection;

4.It can be applied to enhance the culvert;

5.It can be applied as a secondary enhancement after the uniaxial Geogrid soil enhancement, further enhance the soil;

6.It can be applied in mining, tunnel reinforcement.

7.Network used for animal and husbandry;

8.Network used for cage fishing.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

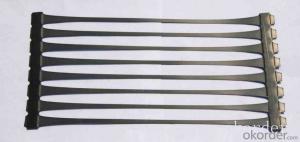

A: Yes, please check the pictures:

- Q: How to connect two-way geogrid

- Transverse 10cm overlap with plastic tape binding on the grid

- Q: How are geogrids installed?

- Geogrids are typically installed by first clearing and grading the surface, then placing a layer of geotextile fabric on the ground. The geogrid is then laid on top of the fabric and secured using stakes or pins. Additional layers of geotextile fabric and fill material may be added as needed, and the geogrid is often connected or overlapped to create a continuous reinforcement layer. Finally, the fill material is compacted over the geogrid to provide stability and support.

- Q: How much is the tensile strength of Geogrid

- Solder paste type: 200KN or less.

- Q: Can geogrids be used in reinforcement of mechanically stabilized earth bridge abutments on collapsible soils?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized earth bridge abutments on collapsible soils. Geogrids are commonly utilized in such applications to improve the stability, strength, and load-bearing capacity of the soil. They help distribute the loads more evenly, reduce settlement, and prevent soil erosion, ensuring the long-term structural integrity of the bridge abutments.

- Q: How to apply the fixed scale of Geogrid

- Remove the geogrid as long as you take the reinforcement of things, such as U type nails, packing belt, gasket, steel nails and other reinforcement, and then roll up on it.

- Q: Can geogrids be used in soil erosion control for agriculture?

- Yes, geogrids can be used in soil erosion control for agriculture. Geogrids are commonly used to reinforce and stabilize soil, preventing erosion caused by water runoff or wind. They provide strength and stability to the soil, reducing the risk of erosion and preserving the integrity of agricultural land.

- Q: What materials are used to make geogrids?

- Geogrids are typically made from materials such as polyester, polyethylene, or polypropylene. These materials are chosen for their strength, durability, and resistance to environmental factors like UV radiation and chemical degradation.

- Q: What are the factors that affect the installation and survivability of geogrids in cold climates?

- The factors that affect the installation and survivability of geogrids in cold climates include the type and quality of geogrid material, proper preparation of the subgrade, adequate compaction of the soil, temperature variations, frost heave, snow accumulation, and freeze-thaw cycles.

- Q: Are geogrids effective in reducing soil settlement?

- Yes, geogrids are effective in reducing soil settlement. They provide reinforcement and stabilization to the soil, preventing excessive settlement and maintaining the integrity of the ground. By distributing the load and increasing the load-bearing capacity of the soil, geogrids help to minimize settlement and ensure long-term stability.

- Q: How much is the geogrid 100KN

- Fiberglass grille price: 5 yuan

Send your message to us

Ground Stabilisation Geogrids - High Modulus Fiberglass Geogrid with High Tensile Strength Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords