Geocells Geogrid Soil Stabilization Wrap Knitting Polyester Geogrid with PVC Coated for Roadbed/Airport/Railway Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wrap Knitting Polyester Geogrid with PVC Coated for Roadbed/Airport/Railway Reinforcement

1. Product Description of Wrap Knitting Polyester Geogrid with PVC Coated for Roadbed/Airport/Railway Reinforcement

Geogrids defined as a grid structure of polymeric material formed by weaving or knitting intersecting ribs with appropriate apertures (opening sizes) to allow interlocking with surrounding soil, rock, earth and other surrounding materials. There are two basic categories of geogrids. Uniaxial geogrids designed to endure stress in one direction. Their main strength is in the machine direction making these grids suitable for wall and slope applications. Biaxial geogrids provide equal strengths in both machine and cross directions making them suitable for bases or foundation application where stresses can occur in any direction. Depending upon manufacturing techniques and materials, geogrids can be designed to resist creep when subjected to high loads for long periods of time or resist high, short-term dynamic loads or moderate loads over longer periods of time.

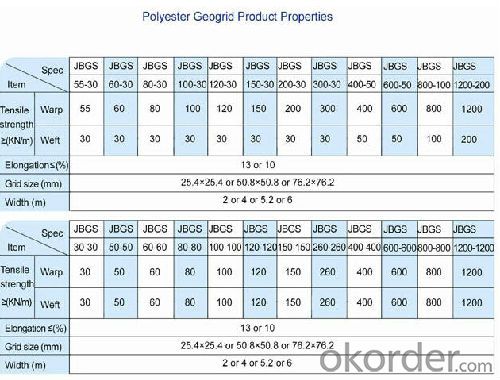

2. Technical Data of Wrap Knitting Polyester Geogrid with PVC Coated for Roadbed/Airport/Railway Reinforcement

3. Functions of Wrap Knitting Polyester Geogrid with PVC Coated for Roadbed/Airport/Railway Reinforcement

1)Reduce costs- apertures designed to work with wide range of fill allowing for the use of less expensive soils.

2)Reduce depth of excavation required on unsuitable sub grades.

3)Increase developable areas without incurring cost of unattractive and expensive retaining wall.

4)Stabilizing slopes increases the strength of soil giving it a higher factor of safety and greater seismic durability.

5)Reduces maintenance and extends the life of the pavement by reducing differential settlement of roadways.

6)Durability – high resistance to soil micro-organisms and chemicals, UV radiation and mechanical damage.

4. Applications of Wrap Knitting Polyester Geogrid with PVC Coated for Roadbed/Airport/Railway Reinforcement

Geogrids focus almost entirely on reinforcement applications, although separation may be a function. The following are examples of a few applications.

1)Slope Reinforcement- embankments over soft soils, extra-steep earthwork slopes, landfill liner systems, and industrial and contaminated land reclamation

2)Base Reinforcement--- foundations of roadbeds, parking lots, railroad tracks beds, airports runways, permanent unpaved roads, construction haul roads

3)Wall Reinforcement--- retaining walls, sea walls, airport noise barriers, and bridge supports

4)Berm Reinforcement --- spillway channels for earthen dams, levees, and waste contaminated ponds, banks for earthen canals and waterways

5. Product Photos of Wrap Knitting Polyester Geogrid with PVC Coated for Roadbed/Airport/Railway Reinforcement

- Q: How do geogrids improve the stability of slopes?

- Geogrids improve the stability of slopes by providing reinforcement and preventing soil movement. They act as a barrier, distributing the forces exerted on the slope more evenly, reducing the risk of slope failure. Geogrids also increase the friction between soil layers, enhancing their shear strength and overall stability.

- Q: Is there a geogrid in the transition section of Railway

- The railway section is to be used in the geogrid

- Q: Glass fiber mesh cloth.

- Mesh is based on alkali or alkali glass fiber yarns, the alkali resistant polymer emulsion coated glass fiber mesh cloth series products: GRC alkali resistant fiberglass mesh cloth, alkali resistant wall enhanced special mesh and stone mosaic, marble back mesh cloth

- Q: Asked the retaining wall engineering grille mistook polypropylene as high density polyethylene, how to do? Is there any remedy?

- What is wrong with the polypropylene in the geogrid in the retaining wall of the road? Performance will not be affected? Is there any remedy?

- Q: How do geogrids improve the performance of flexible retaining walls?

- Geogrids improve the performance of flexible retaining walls by providing additional reinforcement and stability to the structure. They help distribute the lateral forces exerted by the soil, reducing the pressure on the wall and preventing potential failure or deformation. Additionally, geogrids enhance the overall strength and durability of the retaining wall, allowing it to withstand higher loads and maintain its structural integrity over time.

- Q: How do geogrids improve the performance of geosynthetic encased columns?

- Geogrids improve the performance of geosynthetic encased columns by providing additional reinforcement and stability. They enhance the load-bearing capacity of the columns, increase their resistance to lateral movements, and distribute the forces more evenly throughout the structure. Geogrids also help to prevent soil erosion and provide long-term durability to the columns, ultimately improving their overall performance.

- Q: Can geogrids be used in reinforcement of rail embankments and cuttings?

- Yes, geogrids can be used in the reinforcement of rail embankments and cuttings. Geogrids are commonly utilized in civil engineering projects to improve the stability and strength of soil structures. By incorporating geogrids into rail embankments and cuttings, the soil is effectively reinforced, preventing erosion, reducing settlement, and enhancing overall stability. This reinforcement technique helps to ensure the longevity and safety of rail infrastructure.

- Q: Can geogrids be used in foundation stabilization?

- Yes, geogrids can be used in foundation stabilization. They are commonly used in civil engineering and construction projects to reinforce soil and improve the stability of foundations. Geogrids are typically installed horizontally or vertically within the soil to distribute loads and prevent soil movement, thereby enhancing the overall stability and performance of foundations.

- Q: Are geogrids suitable for use in ground reinforcement for solar farms?

- Yes, geogrids are suitable for use in ground reinforcement for solar farms. Geogrids provide excellent soil stabilization, erosion control, and load-bearing capacity, which are crucial for supporting the heavy equipment and structures in solar farms. Additionally, geogrids can enhance the overall stability and longevity of the ground, ensuring efficient and sustainable operation of solar energy infrastructure.

- Q: High density polyethylene one-way geogrid, tensile yield of 20kn/m

- This refers to a material specification for the product,

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Geocells Geogrid Soil Stabilization Wrap Knitting Polyester Geogrid with PVC Coated for Roadbed/Airport/Railway Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 120000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords