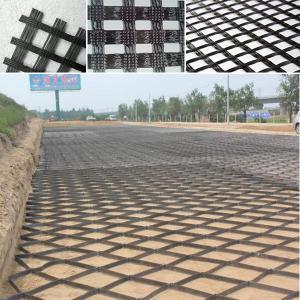

Asphalt Reinforcement Geogrids - PP Biaxial Geogrid 3.95*50m/Roll with High Tensile Strength for Reinforcement Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 12000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Biaxial Geogrid 3.95*50m/Roll with High Tensile Strength for Reinforcement Consturction

1. Specifications and Technical Data for PP Biaxial Geogrid 3.95*50m/Roll with High Tensile Strength for Reinforcement Consturction

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

2. Application for PP Biaxial Geogrid 3.95*50m/Roll with High Tensile Strength for Reinforcement Consturction

1). It can be applied in all kinds of roads, railways, airports to enhance the roadbed;

2). It can be applied in a large car park and terminal freight yard, etc. to strengthen the foundations of a permanent load;

3). It can be applied in rail, road slopes protection;

4). It can be applied to enhance the culvert;

5). It can be applied as a secondary enhancement after the uniaxial Geogrid soil enhancement, further enhance the soil, prevent soil erosion;

6). It can be applied in mining, tunnel reinforcement

3. Packing and Delivery for PP Biaxial Geogrid 3.95*50m/Roll with High Tensile Strength for Reinforcement Consturction

- Q: Can geogrids be used in slope stabilization?

- Yes, geogrids can be used in slope stabilization. Geogrids are often employed to reinforce and stabilize slopes by providing additional strength and resistance to soil erosion. They are effective in preventing slope failures and can be used in various applications such as retaining walls, embankments, and slopes where erosion control is required.

- Q: How much is a glass fiber mesh

- Alkali resistant glass fiber mesh cloth big price difference, and the alkali resistant glass fiber mesh quality, high tensile strength, elasticity, tensile strength and elongation between alkali resistant glass fiber mesh elastic limit, so the glass fiber mesh cloth price range is large, with "Jining wellav" WL-0812 series products the price, floating in the price range of $0.32--5

- Q: Glass fiber grille material.

- In order to protect the glass fiber, improve the overall performance of the use of special coating treatment process of the composite materials.

- Q: What is the meaning of the geogrid reinforced asphalt in the project list

- You are not me, I was the construction of geogrid manufacturers, generally used in the mygeogrid on the road of geogrid is fiberglass geogrid, in your compacted Subgrade after injection will then laying a layer or several layers of fiberglass geogrid, after paving asphalt, the operation process is this, geogrid and asphalt is two kinds of different products

- Q: Can geogrids be used in green wall systems?

- Yes, geogrids can be used in green wall systems. Geogrids provide stability and reinforcement to the structure, helping to support the weight of the green wall system and prevent soil erosion. They can be used to create a strong foundation and provide additional support for the plants, ensuring the success and longevity of the green wall.

- Q: What is the vertical spacing of Geogrid

- Geogrid generally by horizontal and vertical staggered from the simple meaning of space can also be understood that the size of the lattice gap.

- Q: How is the strength of a geogrid determined?

- The strength of a geogrid is determined through various laboratory tests and analysis, including tensile strength testing. This involves subjecting the geogrid to controlled loads and measuring the forces required to cause failure or deformation. Other factors such as the type of polymer used, manufacturing process, and design specifications also contribute to determining the overall strength of a geogrid.

- Q: Are geogrids suitable for use in ground reinforcement for residential developments?

- Yes, geogrids are suitable for use in ground reinforcement for residential developments. They provide excellent soil stabilization and reinforcement, helping to prevent soil erosion, improve load-bearing capacity, and enhance the longevity of residential structures. Geogrids are a cost-effective and sustainable solution for various ground reinforcement applications, making them a suitable choice for residential developments.

- Q: How do geogrids improve the stability of shorelines?

- Geogrids improve the stability of shorelines by providing reinforcement and preventing soil erosion. They are typically placed beneath the soil surface, acting as a stabilizing layer that distributes the applied loads and helps prevent the soil from sliding or slumping. Geogrids also enhance the cohesion between soil particles, increasing the overall stability of the shoreline and resisting the forces of waves, currents, and tides.

- Q: High density polyethylene one-way geogrid, tensile yield of 20kn/m

- Material is high density polyethylene material

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Asphalt Reinforcement Geogrids - PP Biaxial Geogrid 3.95*50m/Roll with High Tensile Strength for Reinforcement Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 12000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords