High Strength Fiberglass Geogrids from Thailand Supplier

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 150000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

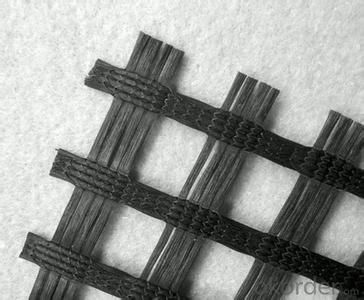

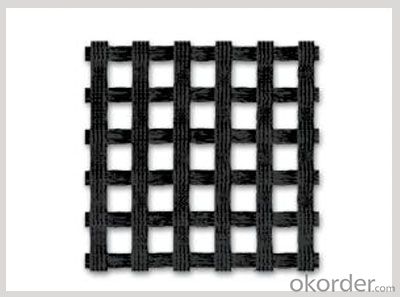

CMAX fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

Performance:

High strength, high modulus and low temperatures resistance

Applications:

Reinforcement for road pavement

Reinforcement for railway basement

Reinforcement for Tunnel

Reinforcement for slope

Reinforcement for embankment.

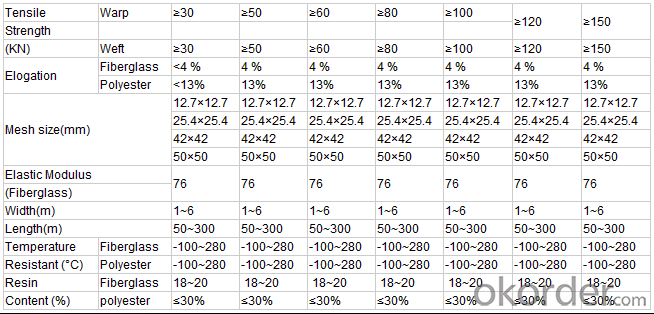

Specifications:

Packing

FAQ

●How long have you been in international trade and geosynthetics industry?

10-year experience in international trade.

20-year experience in geosynthetics field.

●Which payment do you accept?

For you convinience,our payment can be L/C,TT,Westunion,paypal

●Can I know the width you can produce?

Of course we can,our width can be 1 to 6m

●How will you pack the products?

Usually we pack our products by woven bags,also we can do as your requirements

●We want to make sure quality,is free sample available?

We can supply free samples if you need.

- Q: What are the limitations of geogrids?

- Geogrids have a few limitations. Firstly, they are not suitable for all types of soil and terrain conditions. They are most effective in soils with good particle interlock and cohesion. Secondly, geogrids are not effective in situations where there is high water flow or erosion potential as they do not provide sufficient protection against these forces. Additionally, geogrids may have limited strength in certain applications, such as heavy load-bearing scenarios, and may require additional reinforcement. Lastly, the installation and maintenance of geogrids can be complex and costly, requiring skilled labor and regular inspections to ensure proper functioning.

- Q: What are the physical properties of Geosynthetics

- Composite materials sometimes use a thin geomembrane, the thinnest up to 0.1mm; the thickness of the geogrid varies with the location, the thickness of the ribs from 0.5mm to dozens of millimeters.

- Q: What is the typical thickness of a geogrid?

- The typical thickness of a geogrid can vary depending on the specific application and requirements. However, geogrids are commonly available in thicknesses ranging from 0.5 to 2 millimeters.

- Q: Are geogrids effective in preventing soil creep?

- Yes, geogrids are effective in preventing soil creep.

- Q: How to distinguish from the appearance of plastic geogrid and fiberglass geogrid

- Fundamentally different things.。

- Q: What is the recommended overlap distance for geogrid seams?

- The recommended overlap distance for geogrid seams typically ranges from 6 to 12 inches.

- Q: How to calculate the amount of geogrid works under what circumstances need to lay geogrid

- According to the road area, [136] asphalt pavement often laying geogrid [0772], [6164] but if the asphalt is thin, can not. Also like municipal roads will generally be used.

- Q: What are the factors that affect the design and selection of geogrids for geosynthetic reinforcement of steep slopes?

- There are several factors that affect the design and selection of geogrids for geosynthetic reinforcement of steep slopes. These factors include the slope angle, soil type and properties, anticipated loads and stresses, project objectives, and budget constraints. Additionally, site-specific conditions such as climate, drainage, and vegetation should be considered. Properly considering these factors ensures that the selected geogrids are suitable for the specific slope reinforcement needs, providing stability, erosion control, and long-term durability.

- Q: Are geogrids suitable for use in railway ballast reinforcement?

- Yes, geogrids are suitable for use in railway ballast reinforcement. Geogrids provide stabilization and reinforcement to the ballast layer, improving its strength and preventing deformation under heavy loads. They distribute the load more evenly, reducing the risk of settlement and track misalignment. Additionally, geogrids enhance the overall performance and longevity of the railway track by minimizing maintenance and repair needs.

- Q: Fiberglass grille price?

- Fiberglass geogrid 50KN, 2 yuan per squareFiberglass geogrid 80KN, 3.5 yuan per squareFiberglass geogrid 100KN, 4.5 yuan per squareFiberglass geogrid 30KN, 1.7 yuan per squareFiberglass geogrid 40KN, 1.9 yuan per square

Send your message to us

High Strength Fiberglass Geogrids from Thailand Supplier

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 150000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords