High Pressure Hydraulic Postion Dosing Metering Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Pressure Hydraulic Dosing Metering Pump

1.Structure of High Pressure Hydraulic Dosing Metering Pump

Mechnical Diaphragem Dosing Metering Pump offer the high performance with the max capacity flow upto 1200L/H and with outstanding value for pressure up to 12Bar.This series dosing pump is design for durability cost effiectiveness which is welcome to be used in lines such as water treatment,chemical,power,food and beverage,paper etc...

2.Main features of High Pressure Hydraulic Dosing Metering Pump

◆Hydraulic design

◆Power off seal,no leakage,with security delivery device,simple maintance

◆Easy operation

◆It can transport high-viscosity mediums, corrosive liquid and dangerous chemical goods.

◆The flow can be controlled via adjusting the length of stroke or the motor frequency.

◆Verious pump head material(PVC,PVDF,SS304,SS316 etc..)

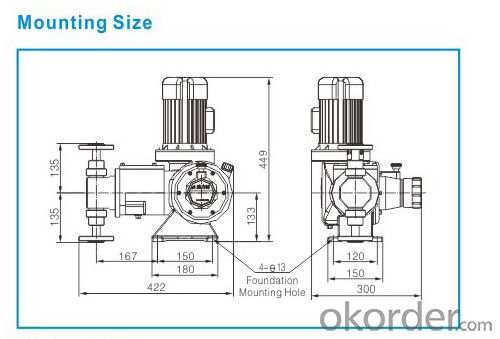

3.High Pressure Hydraulic Dosing Metering Pump Images

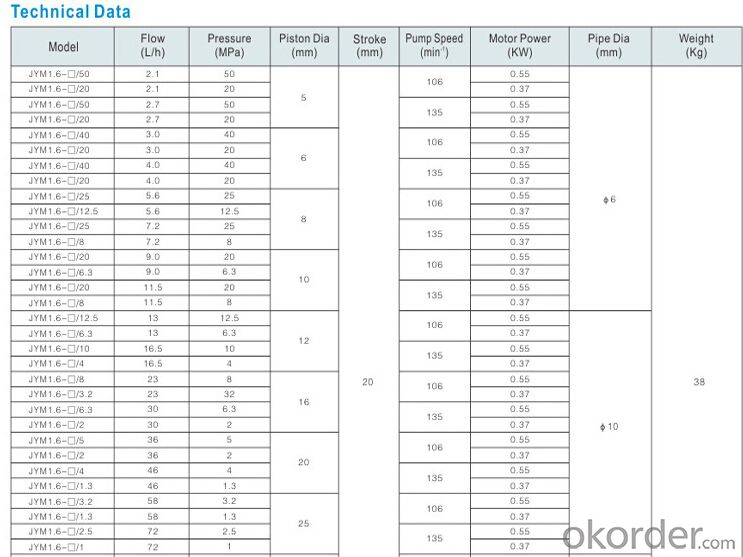

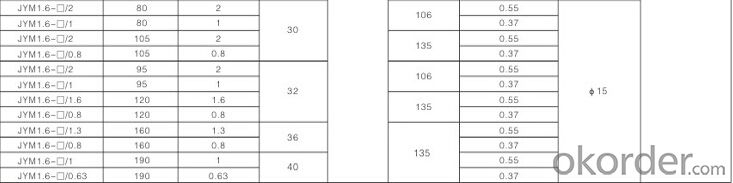

4.High Pressure Hydraulic Dosing Metering PumpSpecification

5.FAQ

·What is the delivery time?

within 20days

- Q: What is a gear pump for?

- Gear oil pump is through a pair of parameters and the same structure of the involute gear of each other rolling meshing, the tank of low pressure oil to work can do the important parts of high pressure oil. A power unit that converts the mechanical energy of an engine into hydraulic energy. The engine is prone to the following faults during its use.

- Q: How much water does the water ring vacuum pump run for an hour? If there is no steam separator, does the water vaporize?

- For example: water storage is relatively small, it needs to reduce the temperature of the heat exchanger. If the tank is relatively large, it does not need cooling water circulation pump again when the temperature is very low, there is no need to heat exchanger. So you need to ask how much water this is not OK.In a soda separator problem:

- Q: What are the characteristics of a pipe shield pump?

- Two, reverse circulation type of shielding pump, its bearings, lubrication, cooling and motor cooling fluid flow direction and the basic type is the opposite. The main characteristic of reverse circulation pump is that it is not easy to generate cavitation. It is suitable for conveying liquid which is easy to vaporize. Sometimes it is also called "easy to vaporize" type. Three, high temperature medium temperature of up to 450 degrees. The cooling water jacket is usually added outside the shielding motor, and a cooling sleeve is added to the outer circulation pipe to cool the high temperature circulating liquid to reduce the temperature of the motor and the bearing. In the case of less power, some manufacturers do not use cooling liquid, but the outside of the motor is equipped with fins and the special winding to adapt to the working conditions, the use of temperature generally can not exceed 400 degrees.

- Q: How is the pump level of submersible sewage pump determined?

- Below the top elevation of the sump, 200 is the warning water levelBut note: 1, the effective volume of the sump meets the requirements. 2, the pump should have enough submerged water level

- Q: What is the function of a submersible pump?Do you have any knowledge about submersible pumps?.

- Important equipment for deep well water extraction. When in use, the whole unit dives into the water. The extraction of groundwater to the surface is water, mine rescue, industrial cooling, irrigation, water lifting, ship ballast, also can be used in fountain landscape, hot water submersible pump for hot spring bath, but also can be applied to the extraction of groundwater from wells, can also be used in rivers, reservoirs, canals and other water projects. The utility model is mainly used for farmland irrigation and water for human and livestock in mountain areas, and can also be used for central air conditioning cooling, heat pump units, cold pump units, cities, factories, railways, mines and site drainage. General flow can reach (10m3~650m3) per hour, head up to 1500 meters.

- Q: Difference between pump and compressor

- Working principle:The impeller is installed in the pump casing and is fastened on the pump shaft 3, and the pump shaft is directly driven by the motor. There is a liquid suction in the center of the pump shell, and 4 is connected with the suction pipe 5. The liquid through the bottom valve 6 and the suction tube into the pump.The liquid discharge port 8 on the pump housing is connected with the discharge pipe 9. Before the pump starts, the pump shell is filled with the liquid to be transported; after starting, the impeller is driven by the shaft to rotate at high speed, and the liquid between the blades must also rotate. Under the influence of centrifugal force, the liquid is thrown from the center of the impeller to the outer edge and obtains energy, and leaves the outer edge of the impeller at high speed to enter the volute pump shell.

- Q: What does centrifugal pump mean horizontally?

- Centrifugal pump horizontal opening meaning: pump shell and pump body along the pump blade horizontal central line is divided into the upper and lower halves, so that the maintenance of pump leaves when the pump top cover can be separated from the pump and bearing as a whole. No need to remove the pipe.

- Q: Common failure treatment of piston pump

- 1) overflow valve regulation is too high, overload after the pump2) the overflow valve spool is blocked, the central hole of the valve core is blocked or the overflow valve is blocked by a damping hole, and the overflow is not overflow3) pump outlet one-way valve installed or spool blocked and stuffy pump4) motor fault x091) adjust the relief valve pressure value2) repair valve boring3) overhaul check valve4) overhaul or replace the motor

- Q: What flowmeter is installed after the pneumatic diaphragm pump?

- The pressure decreases, the diaphragm moves slowly, and the flow decreases.This is not particularly accurate, because the diaphragm is not a metering pump, but the approximate flow can still be controlled.

- Q: How long does the fine stone pump need maintenance? What should I pay attention to?

- nan

Send your message to us

High Pressure Hydraulic Postion Dosing Metering Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords