High Pressure Hydraulic Plunger Postion Dosing Metering Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Pressure Hydraulic Dosing Metering Pump

1.Structure of High Pressure Hydraulic Dosing Metering Pump

Mechnical Diaphragem Dosing Metering Pump offer the high performance with the max capacity flow upto 1200L/H and with outstanding value for pressure up to 12Bar.This series dosing pump is design for durability cost effiectiveness which is welcome to be used in lines such as water treatment,chemical,power,food and beverage,paper etc...

2.Main features of High Pressure Hydraulic Dosing Metering Pump

◆Hydraulic design

◆Power off seal,no leakage,with security delivery device,simple maintance

◆Easy operation

◆It can transport high-viscosity mediums, corrosive liquid and dangerous chemical goods.

◆The flow can be controlled via adjusting the length of stroke or the motor frequency.

◆Verious pump head material(PVC,PVDF,SS304,SS316 etc..)

3.High Pressure Hydraulic Dosing Metering Pump Images

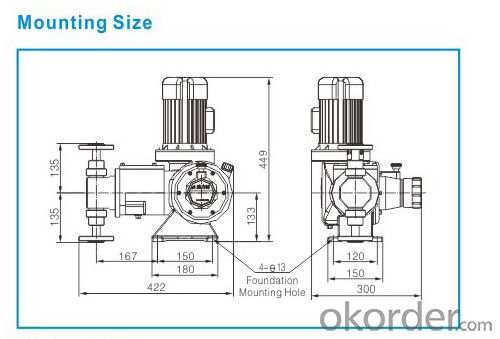

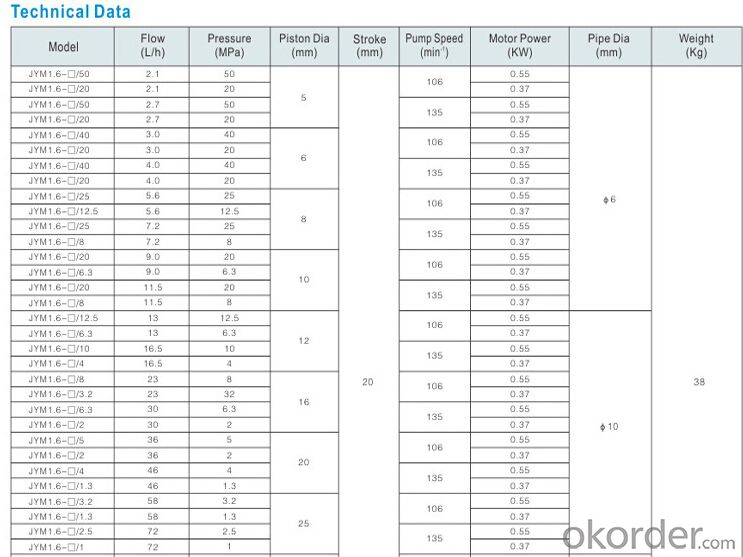

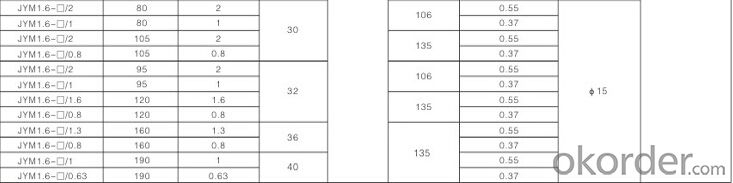

4.High Pressure Hydraulic Dosing Metering PumpSpecification

5.FAQ

·What is the delivery time?

within 20days

- Q: What is the difference between swashplate pump and crankshaft pump?

- Swash plate pump motor is driven as a coaxial swash plate drive plunger pump crankshaft work produces high pressure water in general simply and motor rotor to form a 90 degree angle of the motor through the crankcase to drive the piston to work in general the crankshaft speed is relatively high in the 2800 turn left and right to use the cost of the swash plate speed the use of less than 300 kg pressure in about 1400 when the crankshaft is relatively high but in more than more than 300 kilograms of crankshaft pump highlights his advantage.

- Q: The water tank of the fish tank does not air out and only has the water outlet

- The picture above is very clear, but I didn't say anything about it. My problem is solved. The intake pipe and the exhaust pipe are connected by the inverted T type. The intake pipe is upward, but not fixed. It can be rotated. The intake pipe can be rotated to adjust the number of bubbles

- Q: What does the pump mortar do?

- Concrete pump before the need to transport water and pump pump material, dredge pipeline. In accordance with the technical specification for concrete pumping construction (JGJ/T10 - 1995), pumping concrete, pump mortar generally use cement slurry

- Q: How many millimeters is the diameter of the water outlet of the four inch pump?

- This question is of no practical significance. The user does not care about this figure. The concern should be the nominal diameter, which is fitted with flanges and pipes. Moreover, the pump shell is cast iron, the inside diameter is not processed, and there is no matching parts, there is only one manufacturing size.

- Q: What is the relationship between the minimum suction vacuum of a pump and the required cavitation?

- Suction is allowed to pump the vacuum from the distance from the inlet, which is part of the field installation.The manufacturer of cavitation allowance is closely related to the design and process of pump. Estimation formula: cavitation allowance =10.33 meters - allow suction of -0.5 meters (safety).

- Q: Double floor sewage pump circuit diagram of a small problem

- Q 2, SA and SS are select switches, and different positions indicate the same difference between the two nodes. SA hits the left position 13, 14 to connect, hits to the right position 21, 22 to connect. SS hit the middle position, 5 and 6 turn on, 7 and 8 turn on; hit the right position; 1 and 2 turn on; 11 and 12 turn on; hit the left seat; 9 and 10 turn on; 3, 4 turn on.

- Q: What are the conditions required for hydraulic pumps to complete oil absorption and compression?

- Volume conditions: oil absorption cavity from small to large, complete oil absorption, oil pressure chamber has become smaller, complete pressure oil.Sealing conditions: the hydraulic pump itself should have good sealing

- Q: Centrifugal pump flow, why can be adjusted through the outlet valve? Can the flow of the reciprocating pump be adjusted in the same way?. Why

- Reciprocating pump is a positive displacement pump, the volume change of flow is the unit of time, constant flow speed constant, can not rely on increased resistance to change the flow resistance increase is only leaked, only small changes in flow.

- Q: Filter backwash pump for what use, what is the principle of work ah?

- When the filter is in normal operation, the impurity will be trapped in the upstream of the filter (filter medium). As the accumulation of impurities, the filter media will be blocked, and the direct performance is that the circulation will decrease. Usually, when the flow drops to a set point (the industry is usually judged by the pressure drop),

- Q: What flowmeter is installed after the pneumatic diaphragm pump?

- According to your entire pipeline system to flow meter ah!How about the pressure, the material, the digital float or what?You must be sure of the size of the flow

Send your message to us

High Pressure Hydraulic Plunger Postion Dosing Metering Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords