Hydraulic Plunger Postion Dosing Metering Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Pressure Hydraulic Dosing Metering Pump

1.Structure of High Pressure Hydraulic Dosing Metering Pump

Mechnical Diaphragem Dosing Metering Pump offer the high performance with the max capacity flow upto 1200L/H and with outstanding value for pressure up to 12Bar.This series dosing pump is design for durability cost effiectiveness which is welcome to be used in lines such as water treatment,chemical,power,food and beverage,paper etc...

2.Main features of High Pressure Hydraulic Dosing Metering Pump

◆Hydraulic design

◆Power off seal,no leakage,with security delivery device,simple maintance

◆Easy operation

◆It can transport high-viscosity mediums, corrosive liquid and dangerous chemical goods.

◆The flow can be controlled via adjusting the length of stroke or the motor frequency.

◆Verious pump head material(PVC,PVDF,SS304,SS316 etc..)

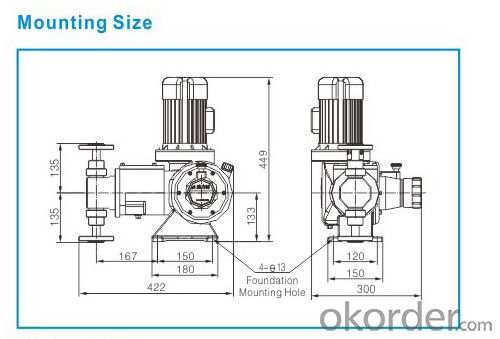

3.High Pressure Hydraulic Dosing Metering Pump Images

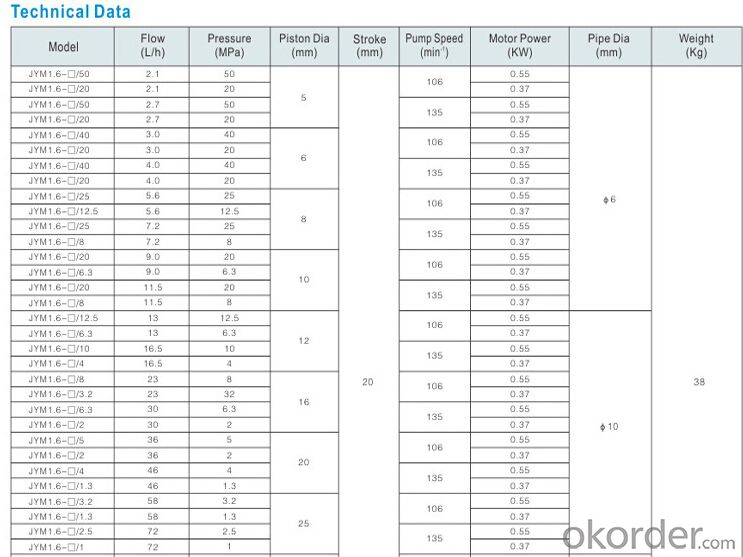

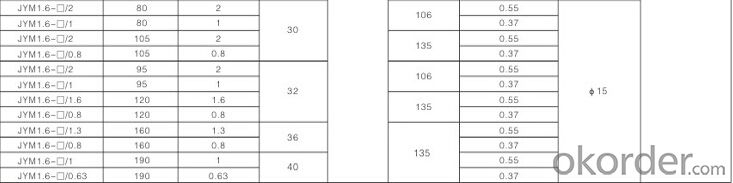

4.High Pressure Hydraulic Dosing Metering PumpSpecification

5.FAQ

·What is the delivery time?

within 20days

- Q: Know flow and lift how to calculate the pump power?

- N=Q.H.g. P / nN - motor power, kWH - pump head, MQ - pump flow, m^3/sG - gravity acceleration g=9.81

- Q: You'd better point out the details.... There are 2 best ways of experience and formulaCan you say a simple point, such as multi-stage pump, when the pump is higher than the motor, 30 wire is the next mouth how to do?

- Looking forAlignment means the position of the center of rotation of the pump and motor so that they are in the same line.At least three times after the initial installation or after installation:

- Q: Troubleshooting of diaphragm pump

- The ratio of flow to water weight at a specific weight of --68F. 68F water has a specific gravity of 1Static suction head - the vertical distance from the liquid level to the central line of the pump. The pump shall be above the level of the liquid.Vapor pressure the pressure of all the steam on the free surface of the liquid. In any pump operating system, the operating pressure shall not be lower than the vapor pressure, otherwise the steam will be partially or completely cut off into the pump fluid. Viscosity - because of the presence of friction in the fluid, the property of viscosity gives the fluid resistance to flow.Water hammer action -Water hammer is a sudden power failure, or in the valve closed too fast, due to pressure, flow of inertia, produce water shock waves, like hammer hammer, so called water hammer. The force produced by the flow of water shock waves can sometimes be very large, thereby damaging the valves and pumps. Water hammer effect refers to the inside of the water pipe, the pipe wall is smooth, flow freely. When the opening of the valve suddenly closes, the flow of water to the valve and the tube wall, mainly the valve, will produce a pressure. As the pipe wall is smooth, the subsequent water flow in the role of inertia, the fastest reach the maximum and damage, which is the water conservancy "water hammer effect", that is, "positive water hammer.". This factor should be taken into consideration in the construction of water conservancy pipelines. On the contrary, the valve closed in a sudden opening, it will produce water hammer, called negative water hammer, but also a certain destructive power, but not the former big.. Causes and treatment methods of common failures of diaphragm pumps:

- Q: What are the functions of a disposable infusion pump?

- With the development of science and technology, more and more fields need to control the flow or velocity of fluid accurately. For example, the detection and analysis of micro chemical elements in chemical industry always need to control the flow accurately. In the field of health care, the flow and velocity of traditional Chinese medicine liquid must be controlled accurately.Venous transfusion is one of the most commonly used methods of clinical treatment. It is a common medication and treatment technique for nursing specialty. Clinically, appropriate infusion rate should be applied according to the drug and patient's condition. Transfusion too fast may cause poisoning, more serious can lead to edema and heart failure;

- Q: Excuse me, what is the water pump from the lotus root?

- Submersible sewage pump with septic tank, outlet pipe automatic coupling installation, dipping down can be.

- Q: Water pump spoon pipe for power plantWhich hero can tell me what is the water pump spoon tube ah? And its role

- The spoon pipe is not a feed pump, but also is an adjusting oil inlet device of a hydraulic coupler matched with a feed pump

- Q: Hydraulic pump displacement refers to the pump shaft what?

- Just as you carry a spoon to the water. How much water can you pump at once (every turn)? That's the displacement.

- Q: Types and differences of pumps

- (I) volumetric typeClassification reciprocating rotary typeThe basic principle of reciprocating action by the piston in the cylinder in the cylinder volume changes again, with the suction and discharge of fluid in the shell or the rotor rotating member rotates, the volume of work between rotor and casing changes to the suction and discharge fluid, such as piston pump gear pump, screw pump(two) blade type;The main structure of vane pumps and fans is rotary, bladed impellers and stationary housings that rotate fluid through the impeller to do work, thereby enabling fluids to obtain energy

- Q: How accurate is the metering pump?

- The measuring accuracy of the stable metering pump is as follows:In a diaphragm metering pump, the reciprocating motion of the plunger is passed to the diaphragm through the hydraulic chamber between the plunger and the diaphragm. In order to maintain the normal movement of the diaphragm, the hydraulic chamber is required to keep the volume of the liquid in the space (usually using hydraulic oil) unchanged. In order to ensure that the volume of the formation of membrane movement is always equal to the stroke volume of the plunger pump, so as to maintain the stability of the flow, but in the actual operation of the pump, the plunger seal will inevitably cause leakage at the same time, there may be a gas into the hydraulic chamber

- Q: Why adjust the centrifugal pump outlet valve can adjust the flow? What are the advantages and disadvantages of this method? Is there any other way to regulate the flow of the pump?

- The centrifugal pump at a fixed speed, the head is fixed, adjust the outlet valve to adjust the diversion area

Send your message to us

Hydraulic Plunger Postion Dosing Metering Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords