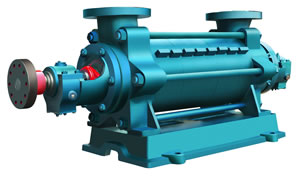

Multi-stage centrifugal pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Type DG: The pumps are suitable for pumping clean water without solid particles or other liquids whose physicochemical property is similar to that of clean water with the temperature range from -20℃~150℃.

Capacity : Q:6~540m2/h

Head : H:33~1056m

Construction: The pump is horizontally installed. The inlet and outlet are under the split surface and in the perpendicular direction with pump central shaft-line, during the course during the course of installation, you needn't to remove the motor and the pipes.

Type SLA is vertically installed the inlet and outlet at a same center line and the case and cover are in the perpendicular direction.

Bearing: Both end of the pump are rolling bearings (type 24SA_18, 16SA_90 could use the sleeve bearings)to support the rotor, the lubrication oil is dilute oil or grease.

Materials of tolerance: The material s of tolerance is cast iron or it can be changed into cast steel and bronze, but it should be signed in the order.

- Q: Must the water pump in the tank be all soaked in water?

- Need a submersible pump in the water, but it is not entirely like this, I have to work for a long time no problem in water, but there is a problem you should pay attention to the water pump, at least in half, or stop when the smoke is not on water.

- Q: How about the depreciation of vacuum pumps?

- (three) appliances, tools, furniture and so on related to the production and operation activities, for 5 years;(four) aircraft, trains, ships and other means of transport for 4 years;

- Q: What are the important parameters of the pump?

- The head is the unit weight of liquid pump pumping from the inlet of the pump (pump inlet flange) to the outlet of the pump (pump outlet flange) energy value. Effective energy is a Newtonian liquid through the pump unit is obtained. The N m/N=m, the height of liquid column pumping liquid used, referred to as meters.Speed nThe speed is the number of revolutions per unit time of the pump shaft. It is indicated by the symbol n. The unit is r/min.Cavitation allowance NPSHCavitation margin, also called net positive suction head, is the main parameter to indicate the cavitation performance. The cavitation margin has been expressed by delta H at homePower and efficiencyThe power of water pump usually refers to the input power, that is, the power transferred by the prime mover to the pump shaft, so it is also called shaft power. It is expressed by P;The effective power of the pump, also known as the output power, is expressed in Pe. It is the effective energy obtained by pumping the liquid out of the pump in unit time

- Q: Shielding pump is the main drawback of electricity? How much does it cost more than an ordinary centrifugal pump? Is there any noise in the running of the canned pump? How much is it lower than the noise of the common centrifugal pump?

- The graphite bearing lubrication medium, make the operation less noise and manual, reduce maintenance costs; in recent years, bearing material added with silicon carbide SIC, super hard, life is better than that of graphite bearing.The vertical structure can be installed on the pipeline like a valve, the installation is convenient and quick, and the motor and the impeller can be drawn out only when the utility model is used, and the pipeline is not needed to be removed.The utility model can be installed and run with a shock absorber or a damping pad, so that the pump is less noisy at running time.

- Q: Operating procedures for measuring pumps

- start-up1. Adjust the stroke indication to zero by adjusting the nut or handle with the rotary stroke.2 open the outlet valve.3. Open the inlet valve, pump, exhaust from the high point, exhaust from the relief valve, the breather valve.4, point motor, check the operation of the pump.5. Start the motor.6, without pressure on the premise, every 15 minutes to improve the stroke 20%, if there is no pressure, do not substantially improve the stroke.Note: (1) whether the sound or vibration of the pump is abnormal (2), whether the stroke adjustment is automatic or not

- Q: What is the working pressure of the hydraulic pump in the hydraulic transmission system?

- Generally speaking, for the fixed size, not limited equipment, the pressure can be selected lower, walking machinery heavy equipment pressure should be selected higher.If the load is selected, the working pressure is as follows:Load <5kN, working pressure <0.8~1MPa;Load 5~10kN, working pressure 1.5~2MPa;Load 10~20kN, working pressure 2.5~3MPa;Load 20~30kN, working pressure 3~4MPa;Load 30~50kN, working pressure 4~5MPa;Load 50kN, working pressure =5MPa;For example, the system work pressure of various machines is as follows:Grinder 0.8~2MPaModular machine tool 3~5MPaLongmen planer 2~8MPaBroaching machine 8~10MPa agricultural machinery, small construction machinery, construction machinery, hydraulic drilling machine 10~18MPa hydraulic machine, large and medium-sized excavators, heavy machinery, lifting transportation machinery 20~32MPa.

- Q: What are the constant pressure pumps?

- Chlorine booster pumpThe pressure range of chlorine booster pump is large, and different pump can be used to obtain different pressure area. The input air pressure is adjusted and the output pressure is adjusted accordingly. High pressure can be reached, gas 90Mpa. Wide range of flow, for all types of pumps only 0.1Kg pressure can work smoothly, at this time to obtain the minimum flow, adjust the intake volume can be obtained after a different flow. Easy to control, from simple manual control to fully automatic control, can meet the requirements. Automatic restart, regardless of what causes the pressure drop in the pressure loop, will automatically restart to supplement leakage pressure and maintain constant loop pressure. Safe operation, gas driven, no arc and spark can be used in dangerous situations.

- Q: Pneumatic diaphragm pump compressed air pressure is 4 kg, the discharge pressure is how big?

- Pigment pressure is less than 0.4mpa,About 0.3. Go up.As the pump diaphragm is in the middle of a connecting rod, equivalent to the cylinder cavity, the pressure will be reduced; and because of the loss of pigment tube pressure will be reduced.

- Q: What is a feed pump?

- Because under normal circumstances, the water pump suction port flow rate is low, can not meet the requirements of high pressure water injection pump. Therefore, the purpose of adding a feeding pump at the front of the water injection pump is to increase the flow rate of the inlet of the high-pressure water injection pump so as to meet its water supply requirements!

- Q: The working principle of magnetic pump

- Magnetic pumpBy the pump magnetic pump, magnetic actuators, motors of three parts. The key components of magnetic actuator by the external magnetic rotor sleeve, inner magnetic rotor and non magnetic components. When the motor drives the outer magnetic rotor, the magnetic field can penetrate the air gap and non-magnetic material, driven by the inner magnetic rotor is connected with the impeller for synchronization the rotation, to achieve non-contact power transmission, the dynamic seal into static seal. As the shaft, the rotor is within a magnetic pump, isolated sets of completely closed to completely solve the problem of "run, run, drip, leak, remove the oil refining chemical industry flammable, explosive, toxic and harmful media through the pump seal leakage security risks, effectively ensure the health and safety of workers.

Send your message to us

Multi-stage centrifugal pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords