High Pressure Hydraulic Chemical Dosing Metering Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Pressure Hydraulic Dosing Metering Pump

1.Structure of High Pressure Hydraulic Dosing Metering Pump

Mechnical Diaphragem Dosing Metering Pump offer the high performance with the max capacity flow upto 1200L/H and with outstanding value for pressure up to 12Bar.This series dosing pump is design for durability cost effiectiveness which is welcome to be used in lines such as water treatment,chemical,power,food and beverage,paper etc...

2.Main features of High Pressure Hydraulic Dosing Metering Pump

◆Hydraulic design

◆Power off seal,no leakage,with security delivery device,simple maintance

◆Easy operation

◆It can transport high-viscosity mediums, corrosive liquid and dangerous chemical goods.

◆The flow can be controlled via adjusting the length of stroke or the motor frequency.

◆Verious pump head material(PVC,PVDF,SS304,SS316 etc..)

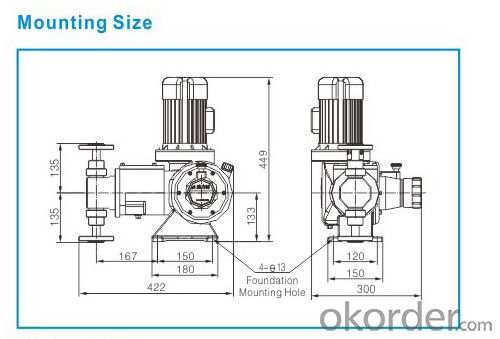

3.High Pressure Hydraulic Dosing Metering Pump Images

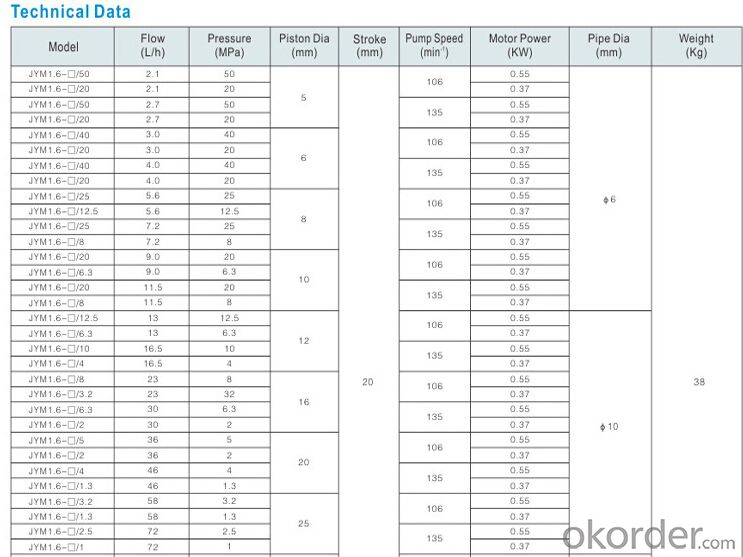

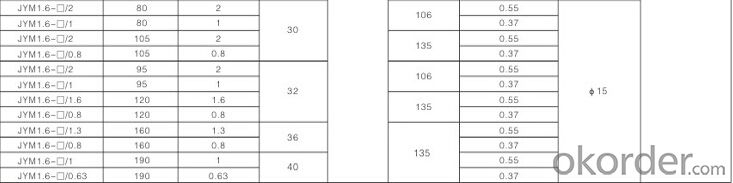

4.High Pressure Hydraulic Dosing Metering PumpSpecification

5.FAQ

·What is the delivery time?

within 20days

- Q: What are the general water pump failure, how to repair?

- (4) because of the long latent water and the corrosion of the pipe wall, the water inlet of the water inlet is constantly dropping. When the holes appear above the water, the air enters the water inlet pipe from the hole.(5) there is a crack at the bend of the inlet pipe, and there is a small gap between the inlet pipe and the water pump, which may cause the air to enter the inlet pipe.

- Q: 5 floor water pressure is too low, what kind of water pump is better?

- Pipe blockage, leaks, or throttling devices are not opened. This can be tested on a pipe with a pressure gauge;Water pump is equipped with power source, power or speed does not match, check the pump and power end nameplate, power end of the pump power is generally 1.1.5 times;

- Q: Troubleshooting of diaphragm pump

- The troubleshooting guide for diaphragm pumps, when encountered in one or more of the following situations, this information can be used as a guide to help you develop maintenance measures.As shown below, some of the abnormal operating conditions described in this guide are: A) fast circulation / low flow B) no cycle / slow cycle / irregular cycle C) leakage D) noise E) component rupture

- Q: What is the principle of a turbopump?

- A machine that converts the energy contained in a fluid medium into mechanical work [turbine]. Also known as turbines, turbines. Turbine is the transliteration of English turbine, derived from the Latin word "turbo", meaning "rotating object". The working conditions of turbines are different from those of the employed ones, so their structure types are various, but the basic working principle is similar. The most important component of a turbine is a rotating element (rotor or impeller) that is mounted on a turbine shaft and has blades uniformly arranged along the circumference. The energy of the fluid is converted into kinetic energy in the flow through the nozzle, and when the fluid passes through the rotor, the fluid impacts the blade and drives the rotor to rotate, thus driving the turbine shaft to rotate. The turbine shaft drives the other machinery directly or through the transmission mechanism, and outputs mechanical work. According to the turbine working fluid used can be divided into different turbine (used as a power source of Hydropower Station) and steam turbine (used in thermal power plant, ship propulsion), gas turbine (used as jet propulsion, ship power, and power plants, with a small peak load power station and air turbine (only) as a small power).

- Q: Why can't the inlet of centrifugal pump be negative pressure?

- However, the centrifugal pump will have its import pressure requirements, which is to prevent cavitation, that is, the fear of the delivery of liquid at low pressure will occur gasification. Centrifugal pump has an important parameter called NPSH, for example relating to the inlet pressure, the pump NPSH, 4 meters, it means that the absolute pressure of imports should be higher than the saturated steam conveying fluid pressure of liquid column is 4 meters high, so, when it is at a temperature of saturated vapor pressure for water transport 2 meters, 4+2=6 meters minimum inlet absolute pressure. Because the absolute pressure is 10 meters water column atmospheric pressure, at this time the entrance negative pressure is 10-6 meters =4 meters water column.

- Q: How to distinguish the flow and displacement in the hydraulic pump? What's the difference between the two?

- The unit of displacement is the milliliter. How many milliliters does the pump rotate per circle? The displacement is the pump, the individual,The unit of flow is generally a liter, a figure added to the displacement of the pump over a period of time,

- Q: Centrifugal pump flow, why can be adjusted through the outlet valve? Can the flow of the reciprocating pump be adjusted in the same way?. Why

- Centrifugal pump, and is a very common method of centrifugal pump, flow with the head (or pressure) increases, off a small valve resistance increases, the pump head should be increased, then the flow decreased, whereas open valve flow increase

- Q: When the water pump is started, why should it start when the outlet valve is closed? Thank you

- The valve opening pump is aimed at the centrifugal pump.From the power curve of the centrifugal pump, the power of the centrifugal pump increases with the increase of the flow rate; the flow curve of the centrifugal pump shows that the flow rate of the centrifugal pump decreases with the increase of the head.

- Q: Because the water pressure of the booster pump is not enough, it can not work automatically. It can only be operated by hand. It is inconvenient to use.

- The worst case is that the pump is not automatic when it leaves the factory, and no one can say whose product is 100%.But there may be automatic control of this piece, not debugging (this depends on the specific product manual or manufacturer)

- Q: What are the failures and causes of the replacement of the fuel pump assembly?

- Failure cause:1) the gasoline pump is too thick with the gasket at the junction of the axle box.2) pump film rupture or pump film and pump shell combination of sealing is not strict.3) the oil inlet valve is stuck or sealed badly.4) severe wear of the rocker arm, reducing the pump film stroke.5) the pipeline from the gasoline tank to the gasoline pump is not smooth, or the pump film spring passes.

Send your message to us

High Pressure Hydraulic Chemical Dosing Metering Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords