Green and Yellow/Blue Nylon Flat Transmission Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Green and Yellow/Blue Nylon Flat Transmission Belt

Application

Widely used in Machinery, textile, printing and dyeing, woodworking machinery, packaging, printing, post and telecommunications, food, stone, metal processing, logistics, tobacco industry

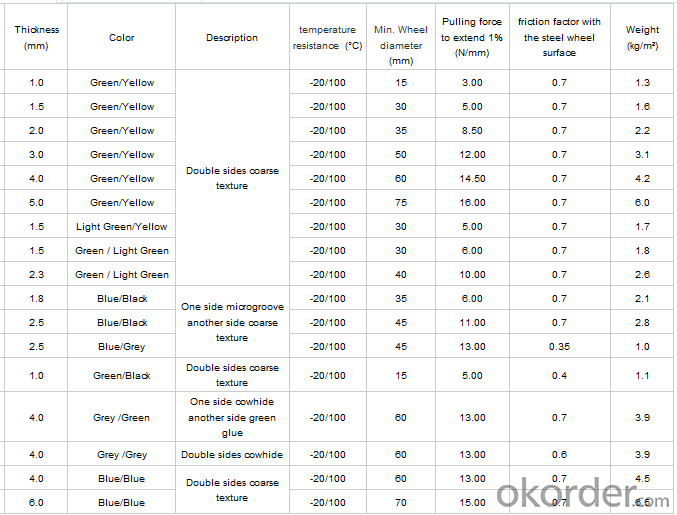

Specifications

Advantage

1. Good elasticity, anti-impact

2. High adhesion, good flexing capacity

3. Stable transmission

4.Good antistatic performance

5. Good resistance to moisture and heat, corrosion resistant

6. Good wear ability and long service life

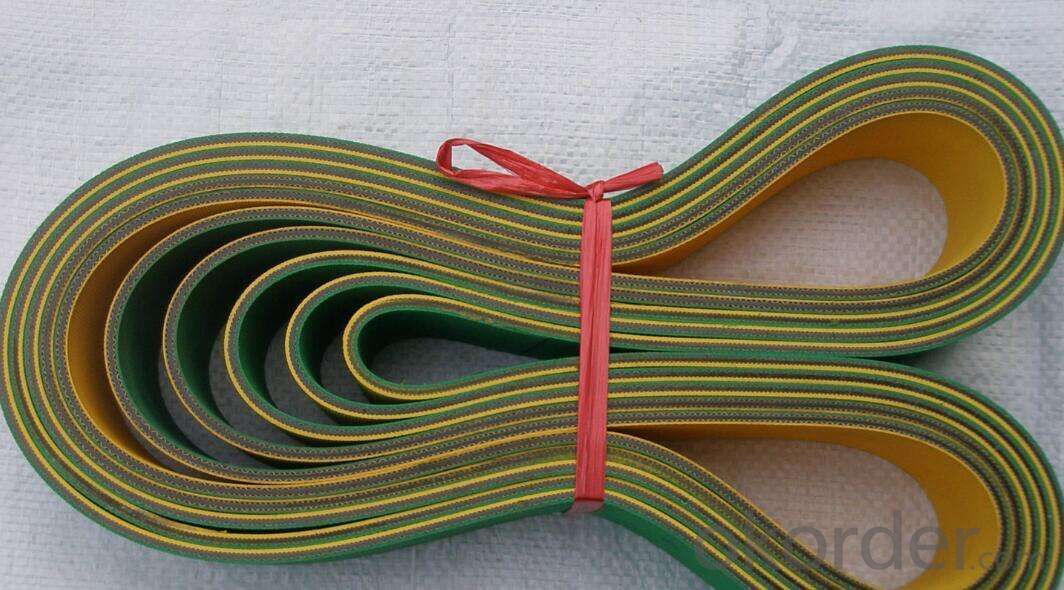

Flat Transmission Belt Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the Flat Transmission Belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What does the rubber tire do to people?

- Rubber is an elastic polymer. Rubber can be obtained from the plant sap, can also be man-made, both have many applications and products, such as tires, washers, etc., has become an important economic crop. The cultivation of rubber is mainly concentrated in Southeast Asia, such as Thailand, Malaysia and Indonesia.

- Q: How much is the recipe for Buddha's rubber?

- Rubber products were analyzed by infrared spectroscopy (FTIR), nuclear magnetic resonance (1H, NMR), mass spectrometry (MS), X diffraction analysis (XRD), ICP-MS, X fluorescence spectrometry, ion chromatography analysis, and other means. Through these testing methods can be a good solution for rubber products formulations, rubber products in the role of a detailed understanding of the more convenient for each enterprise research and development, grasp the market dynamics.

- Q: Several aspects of rubber aging performance and how to identify them

- Oxygen, oxygen free radical chain reaction in rubber with rubber molecules, the molecular chain rupture or excessive crosslinking caused by rubber performance. Oxidation is one of the important reasons for aging of rubber

- Q: Excuse me, what is in the rubber rubber, glue them, what is the difference?

- Rubber is a kind of polymer material with high elasticity, is the parent material manufacturing of rubber products, generally refers to the rubber unvulcanized. Heat the raw rubber to about 120 degrees and keep it warm for more than 5 minutes.

- Q: What are the ingredients in the tires?

- Tires include rubber, polymers, sulfur, carbon black, and other chemicals. Each tire contains more than 150 components, so in the tire production process, from raw material processing to the tire baking to the end, the process is complicated and long.

- Q: How to remove the peculiar smell of rubber products?

- Water - based deodorant is mainly an oil - based water - borne agent, which reduces the flavor of rubber products when neutralized with rubber raw materials. This method is not thorough and effective, generally lasting within one month.

- Q: The action of various ingredients in rubber formula

- Curing system: vulcanizing agent, accelerator, active agent, anti coke agent,

- Q: How to distinguish between silicone hose and rubber tube by appearance?

- Smell, silicone no flavor, rubber flavor, silicone general flexibility better, rubber mechanical better

- Q: What are the causes of chapped rubber products?

- This is the aging phenomenon of rubberAging refers to the polymer materials (including rubber, plastics, fiber and so on) in the processing, storage and use of the process, due to the comprehensive effect of internal and external factors, its performance gradually deteriorated, resulting in the final loss of use value

- Q: How can rubber be made into rubber when it is made?

- Rubber made of rubber products, to be mixed, vulcanized, trimming and many other processes to make rubber products, is a complex processing plant produced.

Send your message to us

Green and Yellow/Blue Nylon Flat Transmission Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords