Textile Industry Flat Nylon Power Transmission Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Textile Industry Flat Nylon Power Transmission Belt

Nylon Transmission Belt

1.Polyamide flat belt

2.largest width is 500mm;

3.Thickness:1.0mm-5.0mm

4.High efficiency low elongation

5.Flexible high fatigue resistance

6.Good antistatic performance

7.Stable friction coefficient

Application

Widely used in Machinery, textile, printing and dyeing, woodworking machinery, packaging, printing, post and telecommunications, food, stone, metal processing, logistics, tobacco industry

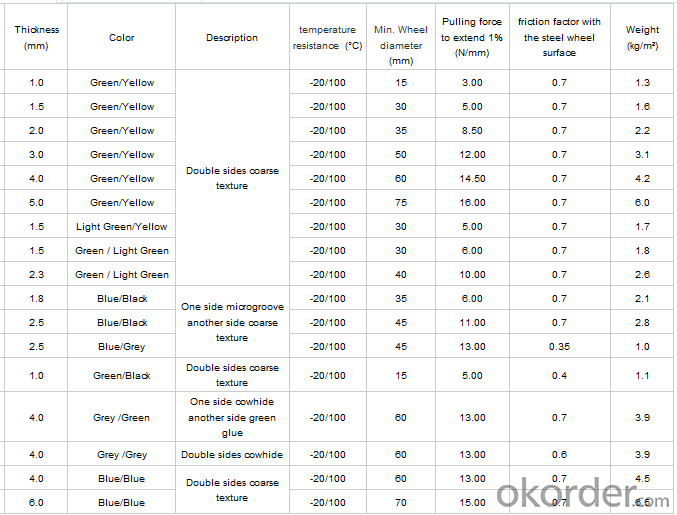

Specifications

Advantage

1. Good elasticity, anti-impact

2. High adhesion, good flexing capacity

3. Stable transmission

4.Good antistatic performance

5. Good resistance to moisture and heat, corrosion resistant

6. Good wear ability and long service life

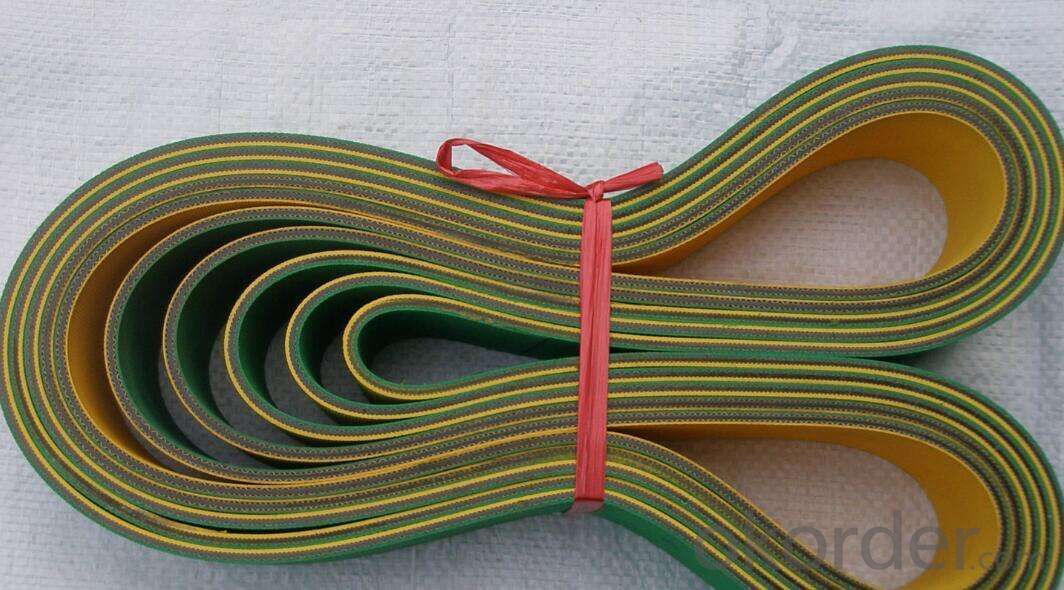

Flat Transmission Belt Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the Flat Transmission Belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: How can I remove the rubber flavor on rubber products? It smells terrible

- This odor is stubborn, more difficult to solve in a short timeThe peculiar smell of a small rubber component in my car used for a week before cleaning it. If the price is not high, I suggest you change it.

- Q: What's the difference between plastic and rubber?

- Plastic has good insulation for electricity, heat and sound: electrical insulation, arc resistance, heat preservation, sound insulation, sound absorption, vibration absorption, noise elimination, and excellent performanceAnd rubberRubber (Rubber): highly elastic polymeric material with reversible deformation. It is elastic at room temperature and can produce great deformation under very little external force. It can be restored to original state after removing external force. Rubber is completely amorphous polymer, its glass transition temperature (T, g) is low, the molecular weight is often large, more than hundreds of thousands. ,Relatively direct, that is, plastic hard, rubber soft (not exactly, there are many exceptions, but most of them are)

- Q: What does the rubber tire do to people?

- Rubber is an elastic polymer. Rubber can be obtained from the plant sap, can also be man-made, both have many applications and products, such as tires, washers, etc., has become an important economic crop. The cultivation of rubber is mainly concentrated in Southeast Asia, such as Thailand, Malaysia and Indonesia.

- Q: What are the causes of cracks in vulcanized rubber products?

- Vulcanized rubber refers to vulcanized rubber, has the characteristics of constant viscosity, not easy to break, and rubber products are mostly made of this kind of rubber. Also known as "mature rubber", commonly known as rubber or rubber. Vulcanized rubber is a polymer compound, its monomers are CIS poly butadiene monomer -CH2-CH=CH=CH2- 1, 3- in the double bonds were open to the -S-S- curing agent, will connect the linear structure of polybutadiene rubber mesh structure.

- Q: How much is the recipe for Buddha's rubber?

- According to the form can be divided into: rubber block rubber, latex, liquid rubber and rubber powder. Latex as a rubber colloidal water dispersion; liquid rubber as an oligomer of rubber, not before the vulcanization is generally viscous liquid; powder rubber is the latex processing into powder, in order to benefit ingredients and processing. Thermoplastic rubber, developed in 1960s, does not require chemical vulcanization and is shaped by thermoplastic processing. Rubber according to the use of divided into general and special type of two categories.

- Q: What kinds of rubber are edible grade safety rubber?

- Natural latex sterilized as condoms, natural rubber or butyl glue used in oral liquid or infusion bottle glue plug, silica gel is most commonly used in the body false organs, mainly stable, no bacteria and so on.

- Q: Why is rubber forest a green desert?

- Rubber is a plant in tropical rain forests, but not native to tropical rainforests in Xishuangbanna. Before the world know it, the growth of rubber trees in South America's Amazon jungle, as long as cut open a gap, there will be a sap from the trunk stream, in the Indian language it is called the "cry of the tree".

- Q: Is silicone good or rubber good?

- If it is inorganic silica gel, that does not need to compare. How do you put different kinds of things together, or do you say good fruit or electric fans? If organic silicone, then the outlook is good, but can not simply say better than ordinary rubber and bad, different places have different applications.

- Q: How to solve the exhaust problem in rubber vulcanization process

- Rubber vulcanization process is a process of high temperature, temperature control, temperature will have material evaporation, products not dense gap, excess glue extrusion emissions, sulfide gas release of many factors such as rubber vulcanization requirements must exhaust can produce qualified products.

- Q: What is rubber made of?

- High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

Send your message to us

Textile Industry Flat Nylon Power Transmission Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords