Conveyor Belt Idlers

Conveyor Belt Idlers Related Searches

Portable Belt Conveyors Inclined Conveyor Belt Stainless Steel Conveyors Small Conveyor Belt Systems Conveyor Belt Vulcanizing Press Containment Liners Ship Propeler Stainless Steel Colanders Stainless Steel Tankers Stainless Steel Belt Buckles Conveyor Rail Environmental Controllers Roller Pulley Wheels Heavy Duty Drawer Rollers Machine Spindles Stainless Steel Welders Stainless Steel Cutters Stainless Steel Bollards Stainless Steel Blenders Stainless Steel Drawers Bulk Vessel Tracking Commercial Truck Shelving Cordless Cellular Blinds Stainless Steel Coasters Cargo Van Shelving Stainless Steel Casters Stainless Steel Tweezers Stainless Steel Weights Acme Boat Propellers Environmental LinersConveyor Belt Idlers Supplier & Manufacturer from China

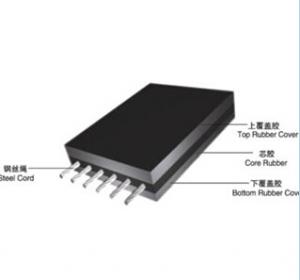

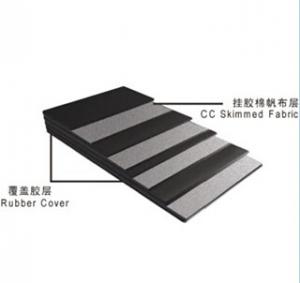

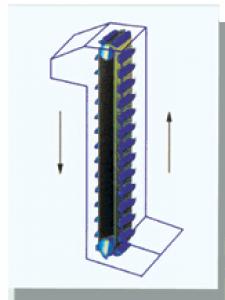

Conveyor Belt Idlers are essential components in the conveyor system, designed to support and guide the belt while reducing friction and maintaining its proper alignment. These idlers come in various types, such as impact idlers, return idlers, and transition idlers, each serving a specific purpose within the conveyor system. They are crucial for the efficient operation of material handling processes in industries like mining, construction, and manufacturing.In various application and usage scenarios, Conveyor Belt Idlers play a vital role in ensuring the smooth and uninterrupted flow of materials. They help in reducing wear and tear on the conveyor belt, which in turn increases the lifespan of the belt and minimizes maintenance costs. By maintaining proper tension and alignment, idlers contribute to the overall efficiency and productivity of the conveyor system, making them indispensable in a wide range of industrial settings.

Okorder.com is a leading wholesale supplier of Conveyor Belt Idlers, boasting a large inventory that caters to the diverse needs of customers worldwide. With a commitment to quality and customer satisfaction, Okorder.com offers a comprehensive range of idler products, ensuring that clients can find the perfect fit for their specific conveyor system requirements.

Hot Products