PVC PU Endless Conveyor Belt High Tensile Green White Flat Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC PU Endless Conveyor Belt High Tensile Green White Flat Belt

Specifications:

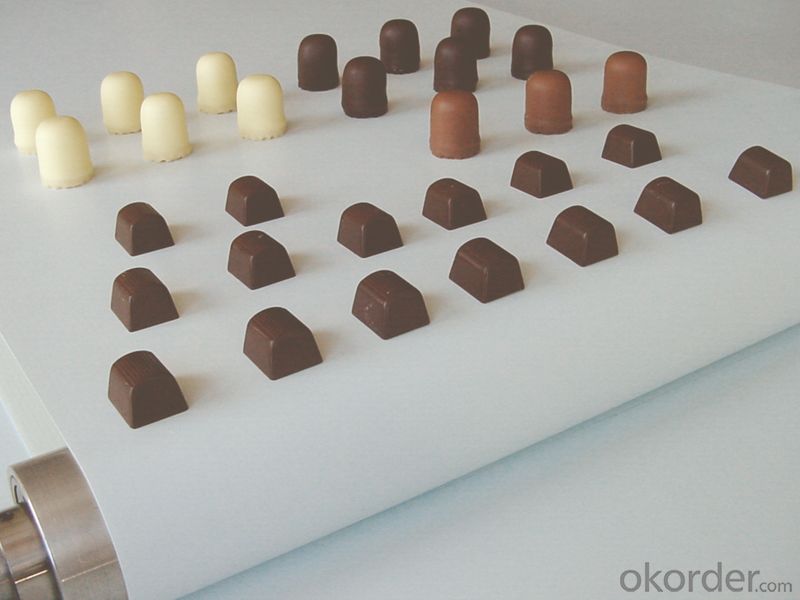

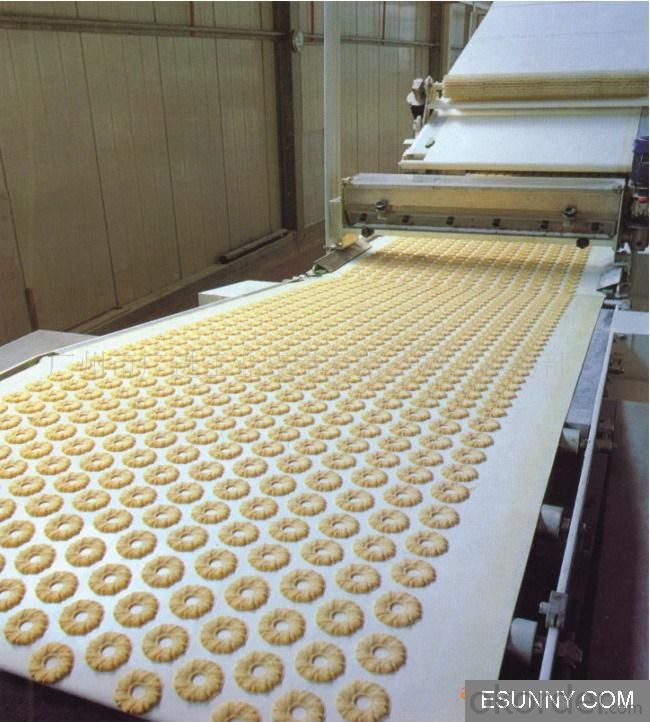

The PVC conveyor belts are manufactured using high quality material.It features largely in the high strength, stable conveyance performance. Besides, it is fire retardant, anti-static, shock resistant, wearable and corrosion resistant. Our food conveyor belts are FDA/USDA approved and most types also have USDA Dairy Approvedand support your HACCP concept.

Features:

1. Non-Conductive

2. Anti-Static

3. Resistant to fats, chemicals, oil fat and abrasion

4. Various surfaces with high, medium and low coefficient friction

Applications

Most popular application include operations in the Sugar IndustryFood Products Organizations mainly use Hygienic Belts for their bulk handling packed materials.

Tea Estates are major users of Hygienic Belts for conveying of various varieties of Green Tea Leaves and forward conveying the same towards Drier Sections, and finally for the packed products.

Pharmaceutical Sectors are major user of Hygienic Belts in their manufacturing units for medicines and packing departments.

PVC Solid Woven Conveyor Belt:

Ø Suitable for applications in dry conditions at a slope angle of no greater than 16 degrees.

Ø Cover thickness can be from 0.5 to 4mm.

Ø Nitrile covered PVG type

Ø Suitable for applications at a slope angle of less than 20 degrees, thickness can be 1 to 18mm.

Ø Resistance to wetness, slip, low temperature and wear resistance of the belt.

| Specification | Thickness (mm) | Color | Style |

| 1 ply fabric~1 ply p | 1 | green/white | plain |

| 1 ply fabric~2 ply p | 2/3/4/5 | green/white | skirt lace |

| 2 ply fabric~2 ply p | 2/3 | white/B.matt/green | diamond with small dot/grass |

| 2 ply fabric~3 ply p | 3 | green | diamond |

| 3 ply fabric~3 ply p | 4/5/6/7 | white/green matt | network wire |

| 3 ply fabric~4 ply p | 4/5 | green | diamond |

| 4 ply fabric~4 ply p | 9 | green matt | marble |

Above the form just list a part, we can product as your requirement, welcome to negotiate.

Pls contact me freely if any inquiry,thank you!

- Q: What is the tensile strength of silicone rubber?

- The tensile strength range of silicone rubber is 3.4-14.7Mpa, depending on the formula!

- Q: How does rubber mobile phone cover change yellow?

- Rubber aging process often accompanied by some significant phenomena, such as the appearance of natural rubber can be found in long-term storage of soft, sticky, spots; rubber deformation, brittle, hard, cracking, mildew, loss of light and color change.

- Q: What advantage does ethylene propylene rubber with three yuan compare to two yuan ethylene propylene rubber?

- In recent years, the third monomer and new technology development, foreign developed 1 7- octadienoic, 6, 5, two 10- methyl -1, 9- eleven, 7- two three ene 3, methyl -1, 6- octadienoic, 5 7-, two methyl -1, 6- octadienoic, 7- methyl -1, 6- octadiene as the three EPDM third monomer, the performance of three Yuan rubber has been enhanced. The monomer and content of third monomer in three yuan ethylene propylene rubber have direct influence on vulcanization rate and vulcanizate property. Among them, dicyclopentadiene (DCPD) as the third monomer, although the price is low, but the three Yuan rubber vulcanization speed is slow, difficult and high degree of unsaturation diene rubber and use; to ethyiidenenorbomene (ENB), 6 10-, two methyl -1, 5, third monomer three Yuan rubber vulcanization speed 9- eleven three ene as fast, the former has become the main varieties of three yuan of ethylene propylene rubber. The third monomer content in iodine said three EPDM iodine value is generally 6-30, mostly around 15. The iodine value is 6-10, curing speed is slow, difficult and high unsaturated rubber; iodine value is 25-30, for ultra high speed curing type, available in any proportion and high unsaturated diene rubber and use. Therefore, three yuan ethylene propylene rubber and other rubber in use, should pay attention to choose the appropriate three yuan ethylene propylene rubber varieties.

- Q: Aging of rubber parts for automobiles

- The engine bracket, the foot pad, the leaf spring bushing, and the shock absorbing foot cushion, such as rubber aging, will vibrate abnormally and cause abnormal noise, which will cause the damage of the whole component and even the radiation to the surrounding parts. In addition, the rubber bushings on the trucks need to be replaced, it is not an easy task and sometimes requires larger actions. For example, the shock absorber rubber of the cab needs to be lifted if it needs to be replaced.

- Q: How to make white rubber products do not yellow or delay yellowing time?

- The process of yellowing resistance is very complicated and involves many aspects, but the prevention of a certain point is not up to standard.Yellow change is mainly formed by aging. Controlling yellowing is the process of controlling aging.

- Q: Does it work in a rubber factory that causes skin irritations?

- Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

- Q: What are the ingredients in the tires?

- Tires are usually composed of 3 parts of tyre, tyre, cushion belt. The inner layer of the fetus body has the rubber layer with good air tightness, and a special wheel rim is required. The structure of tire in the world has been developed in the direction of tubeless, radial structure, flat (smaller ratio of height to width of tire section) and light weight.

- Q: Doors and windows shock absorber seals, rubber blocks, rubber products, do not know where to buy, where suppliers?

- The product has good elasticity and anti compression deformation, and has excellent aging resistance. It adopts the microwave vulcanization process to form at one time. The surface is smooth and beautiful, without any trace.

- Q: What is the difference between PVC rubber and ordinary rubber?

- PVC is polyvinyl chloride (with "green" sound) vinyl, English PVC (Polyvinyl chloride), is a vinyl chloride monomer (vinyl chloride monomer, referred to as VCM) in peroxide, such as azo compound initiator; or in light, under the action of heat polymerization by free radical reaction mechanism of polymerization of polymers.

- Q: What about rubber molding, foaming and layering?

- Foaming1 vulcanization is not sufficient, the temperature is too low or time is too short, so that the volatile compounds produced during curing have not been cleaned out;2, under the pressure of vulcanization, the trapped gas and sulfur volatile matter can not be discharged in time3, there is air or moisture in the glue;4, curing temperature is too high, the surface of the gum material premature vulcanization, hindered the glue material in the steam, air free precipitation5 vulcanization speed of material is too fast

Send your message to us

PVC PU Endless Conveyor Belt High Tensile Green White Flat Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords