High Quality ISO Standard Food Industry PVC/PU Conveyor Belt Flat Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality ISO Standard Food Industry PVC/PU Conveyor Belt Flat Conveyor Belt

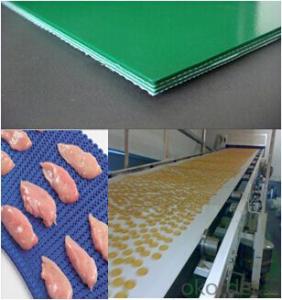

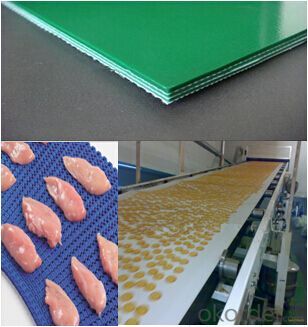

PVC/PU Conveyor Belt:

Anti-static and tearing resistant

Abrasion and oil/heat/fire resistant

Application:

PVC Conveyor belt has a wide range of products which can be applied in different industries, such as: tobacco, food, logistics, post, airport machinery, phamaceuticals, chemistry, electronics, printing, cable pulling, steel wrapping and sports entertainment.

Product Feature

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise

| Top cover | Bottom Cover | Characte ristics | Temp.℃ | FABRIC Plies | Max. Width | |||

| Colour | Surface | Colour | Surface | Min | Max | |||

| White | Smooth | Natural | Impregnated | Antistatic | -15 | 90 | 1 | 2000 |

| White | Matt | Natural | Impregnated | Antistatic | -15 | 90 | 2 | 2000 |

Dark Green | Matt | Natural | Impregnated | Antistatic | -15 | 90 | 2 | 2000 |

| White | Smooth | Natural | Fabric | Antistatic | -15 | 90 | 2 | 2000 |

| White | Smooth | Natural | Fabric | Knife Edge Application | -15 | 90 | 2 | 2000 |

Product Image

Pls contact me freely if any inquiry or questions,thank you!

- Q: What solvent is used to clear the melted rubber layer?

- The acetone extractives are some fatty acids and steroids, some natural antioxidants and accelerators, and can help with the powdery agent in the process of mixing and dispersion of rubber softening effect.Ash containing mainly magnesium phosphate and calcium phosphate salts, copper, manganese, iron and other metal compounds is very small, because these valence metal ion can promote the aging of rubber, so their content should be controlled.

- Q: What's the difference between rubber and silicone?

- The definitions are different. Rubber is a term that contains many types, such as natural rubber, butadiene rubber, styrene butadiene rubber, acrylic rubber has, including silicone rubber; silicone rubber is one of the specific varieties.

- Q: What does the rubber tire do to people?

- Rubber is an elastic polymer. Rubber can be obtained from the plant sap, can also be man-made, both have many applications and products, such as tires, washers, etc., has become an important economic crop. The cultivation of rubber is mainly concentrated in Southeast Asia, such as Thailand, Malaysia and Indonesia.

- Q: Are rubber products poisonous? What harm?

- The rubber is safe when the formula and the ingredients are guaranteed. The cork of the saltwater bottle used for hanging water is rubber.But fear of raw material is not reliable, so you can not answer your questions accurately, only about introduction.

- Q: What is the pressure on rubber products during vulcanization?

- Usually, the selection of curing pressure need to consider several factors, namely rubber formulation, rubber plastic size, forming die structure (filling pressure, injection pressure, injection type), type of curing equipment (flat vulcanizing machine, vulcanizing machine, injection machine, injection of sulfur with sulfide vacuum machine etc.) and product structure features.

- Q: UV glue can glue rubber products?

- If only the outside screen is glued, the UV glue with a surface fixing type is OK (if the crack is too big and the glue can seep in, it is not recommended to mend), but the crack can still be seen.

- Q: Half finished rubber film surface white is going on

- Rubber is a latex made from rubber, tree, rubber, and grass. It is made of flexible, insulating, impermeable and air. High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

- Q: Doors and windows shock absorber seals, rubber blocks, rubber products, do not know where to buy, where suppliers?

- If you buy less friends, you can go to the local building materials market decoration city to see, there will be.But if you buy more and want to find a manufacturer, I suggest you go to some of these forums to see if there is a suitable one.I have seen in Ali on a walk of rubber products, the products are Hebei Great Wall Co seal brand, is the first domestic production of spiral tube protection sleeve manufacturers, professional development, production and sales of rubber products such as rubber seal, seal, rubber protective sleeve

- Q: What is rubber leather?

- Rubber (Rubber): highly elastic polymeric material with reversible deformation. It is elastic at room temperature and can produce great deformation under very little external force. It can be restored to original state after removing external force. Rubber is completely amorphous polymer, its glass transition temperature (T, g) is low, the molecular weight is often large, more than hundreds of thousands.

- Q: What is the difference between rubber expansion joint and rubber joint?

- It is divided into 3 kinds: flange type, fixed flange type and thread type by connection. The structure can be divided into single sphere, double sphere and curved sphere. A tubular rubber component is composed of inner and outer layers of rubber, cord and steel ring, which is vulcanized and molded and then combined with a metal flange or a parallel joint. This product can reduce vibration and noise, and can be compensated by thermal expansion and cold contraction due to temperature changes. It is widely used in various piping systems. Rubber joint is a kind of pipe joint with high elasticity, high air tightness, medium resistance and weather resistance. The product uses rubber elasticity, high air tightness, medium resistance, weather resistance and radiation resistance etc., using polyester cord fabric skew high strength, strong stability and the hot and cold composite, after high pressure, mold temperature and curing. As the rubber joint has good comprehensive performance, it mainly acts as shock absorption, noise elimination and noise reduction. Therefore, it is widely used in chemical, construction, water supply, drainage, petroleum, light and heavy industries, freezing, sanitation, plumbing, fire fighting, power and other infrastructure projects.

Send your message to us

High Quality ISO Standard Food Industry PVC/PU Conveyor Belt Flat Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords