Super Fine Recycled Rubber

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Metric Tons m.t.

- Supply Capability:

- 1500 Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

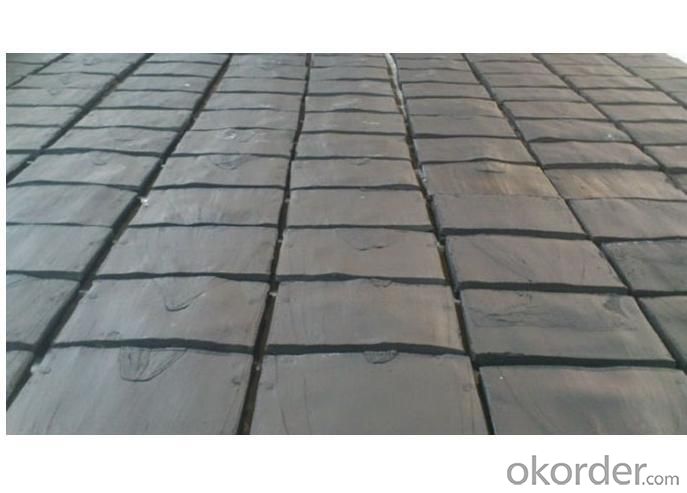

Detailed Product Description of Super Fine Recycled Rubber

1.smell free

2.rosh,pahs standard

3.paintings do not turn yellow by pahs free

4.fast delivery and good service

Introduction of Super Fine Recycled Rubber

We are professional manufacturer of all kinds of odorless reclaimed rubber with nearly ten years experience

Material of Super Fine Recycled Rubber

All our materials are waste tyre with diameter more than 900mm,we can only use tire roof for much top quality reclaimed rubber production

Advantage of Super Fine Recycled Rubber

Competitive prices

Smell free

ROSH,PAHS EU Standard

Fast delivery and good service

The paintings don't change yellow if use our pahs reclaimed rubber

Application of Super Fine Recycled Rubber

Tires

Conveyor belts

Rubber sheets

Rubber hoses

Rubber gaskets

Rubber mats

Rubber bricks

Personalized customization of Super Fine Recycled Rubber

We can produce according to clients special requirments

Specifications of Super Fine Recycled Rubber

Item No. |

Advantage |

Tensile Strength |

Elongation (E.B) |

Mooney Viscosity |

Gravity |

Hardness |

Mpa |

% |

VR |

g/cm3 |

A | ||

TR01 |

1.Smell Free |

7.0 |

285 |

62-68 |

1.35 |

60-70 |

TR02 |

1.Smell Free |

8.0 |

310 |

55-60 |

1.3 |

55-65 |

TR03 |

1.Smell Free |

8.5 |

320 |

55-60 |

1.25 |

55-65 |

TR04 |

1.Smell Free |

9.0 |

330 |

58-62 |

1.2 |

50-60 |

TR05 |

1.Smell Free |

10.0 |

340 |

58-62 |

1.2 |

50-55 |

RR01 |

1.Smell Free;

2.Rohs |

7.0 |

285 |

62-68 |

1.35 |

60-70 |

RR02 |

1.Smell Free;

2.Rohs |

8.0 |

310 |

55-60 |

1.3 |

55-65 |

RR03 |

1.Smell Free;

2.Rohs |

8.5 |

320 |

55-60 |

1.25 |

55-65 |

RR04 |

1.Smell Free;

2.Rohs |

9.0 |

330 |

58-62 |

1.2 |

50-60 |

RR05 |

1.Smell Free;

2.Rohs |

10.0 |

340 |

58-62 |

1.2 |

50-55 |

PR01 |

1.Smell Free;

2.Rohs; 3.Pahs |

8.5 |

320 |

55-60 |

1.25 |

55-65 |

- Q: What are the application fields of waste tire rubber powder?

- Waste tire rubber powder modified asphalt for highway, waterproofing materials, modified concrete, modified coating, railway sleepers, rubber brick, machine pad, cushion, cushion and other types of subgrade gasket and fenders, sound-absorbing materials, road sealant, shoes, carpet padding, tire pad, car body, bottom sealing rings miscellaneous pieces of rubber, etc..

- Q: Why is rubber forest a green desert?

- Long ago, the people have the knowledge of the use of wild rubber. Before Columbo came to the new world, no one outside the Americas knew that there was a species called rubber, and never thought that there would be a magical liquid out of the tree trunk that could change the progress of human civilization one day.

- Q: Are natural latex rubber products?

- Non rubber components contain proteins, lipids, sugars, and inorganic compounds, some of which are compounded with rubber particles, partially dissolved in whey or form non rubber particles. Natural rubber is a kind of polyisoprene as the main component of natural polymer, the molecular formula is (C5H8) n, 91%~94% in its composition is rubber hydrocarbon (polyisoprene), the protein, fatty acid, carbohydrate, ash and other non rubber substances. Natural rubber is the most widely used universal rubber.

- Q: What kind of materials should be used for rubber products to keep the brightness of the mirror for a long time?

- It is important to use recycled material as a high light material. If the selected material is not available, then it is not effective. It must be pure, only ABS.PMMA, or PC/ABS. There is material, it is best not to contain white material, mottled with a little transparent, is the best.

- Q: Does anyone know how to deal with the frosting of rubber and how to prevent it?

- The situation of frost spray often occurs in rubber products, except for formulation reasons and weather. From the stage of occurrence, it may happen before sulfuration or after sulfuration.

- Q: What are the ingredients in the tires?

- Tires are usually composed of 3 parts of tyre, tyre, cushion belt. The inner layer of the fetus body has the rubber layer with good air tightness, and a special wheel rim is required. The structure of tire in the world has been developed in the direction of tubeless, radial structure, flat (smaller ratio of height to width of tire section) and light weight.

- Q: Can rubber products be injection molded and plastic injection functions?

- Rubber products can be injection molding, plastic injection function.

- Q: Rubber products are not allowed to touch oil products, but why can rubber gloves be contacted daily? What's the point?

- Most rubber materials are not resistant to oil, some rubber materials are resistant to oil, such as nitrile rubber, etc., the family commonly used detergent on rubber gloves did not affect.

- Q: What are the causes of fracture in rubber products?

- If it is because of aging and fracture, this is a normal phenomenon, is not a problem in the safe use period, there is to pay attention to the storage environment, avoid direct sunlight, the best placed in the shade, not stored in a humid environment.

- Q: How can I get rid of the rubber?

- You smell the smell from the vulcanized rubber residues, not much of the flavor is generally placed in a cool ventilated place, you can, and if the smell is large, you can use rubber deodorant, supermarkets generally sell

1. Manufacturer Overview

| Location | Shandong, China (Mainland) |

| Year Established | 2006 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Oceania Eastern Asia Western Europe Northern Europe South Asia |

| Company Certifications | Pahs; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | QINGDAO |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High and/or Average |

Send your message to us

Super Fine Recycled Rubber

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Metric Tons m.t.

- Supply Capability:

- 1500 Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords