Auto Windshield Rubber Seal Strip for Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Auto Windshield Rubber Seal Strip for Sale:

1. Brief Description of Auto Windshield Rubber Seal Strip for Sale

Rubber seal strip are usually made by EPDM,for it has many good performance,such as anti-aging,anti-ozone,low and high tempreture resistance,waterproof,etc.And EPDM is easy to be compound with steel,coating,fiber and other material.

You also can choose special material such as NR,CR,SBR,SILICONE,PVC,TPE,TPV for special usage.

2. Main Features of Auto Windshield Rubber Seal Strip for Sale

1).good anti-friction,anti-aging, anti-corrosion effect

2). Weather proof, vandal proof, and can be shaped, molded, painted and screen printed.

3). Non-corrosive, non-toxic and chemical resistant .

4). Soft with high impact strength .

5). Non-warping and stain proof.

6). Easy to clean and maintain .

7). Easy to operate, including glue, nail, cut or shape.

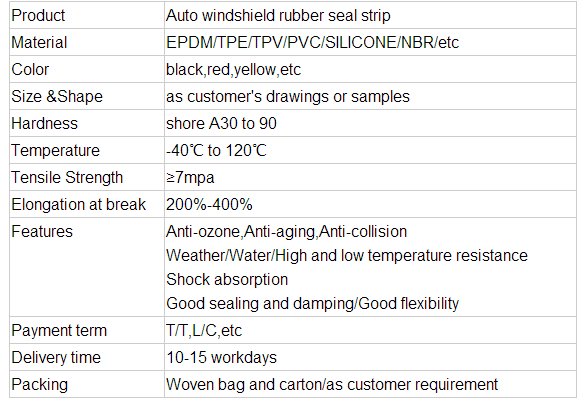

3. Main Specification of Auto Windshield Rubber Seal Strip for Sale

4. Pictures of Auto Windshield Rubber Seal Strip for Sale

5. FAQ

1.Q:Are you a factory or trading company?

A:We are a factory.

2.Q:Can you ensure your quality?

A:Yes,our products have past ISO certificate.We have specialized technical department and

QC team,we will strictly check the material.color,size,performance of the sample step by

step.And every item will be checked before packing.

3.Q:Can you delivery the products on time?

A:Our factory have a production capacity of 400T/month.We will calculate the special delivery

time for you,and ensure the arranged delivery time.

4.Q:Why I choose your products?

A:We can produce the products strictly as your request,and our price is according to the

product material cost,technology cost,labor cost,and other necessary cost.Our price will be

reasonable.

5.Q:Can I get some samples?

A:We offer free sample.

6.Q:Can I visit your factory?

A:Yes, welcome to visit our factory.

- Q: Are there formaldehyde in rubber products, too?

- Yes, because formaldehyde is a very good organic solvent, so the general rubber varieties contain formaldehyde.

- Q: What solvent is used to clear the melted rubber layer?

- Natural rubber is made from latex, and a portion of the non - rubber contained in the latex is left in the solid rubber. In general natural rubber contains rubber hydrocarbon 92%-95%, but not rubber hydrocarbon accounts for 5%-8%. Because of the different processing methods, different habitats and even different seasons, the proportion of these ingredients may vary, but basically within the scope.Proteins can promote the vulcanization of rubber and retard aging. On the other hand, the protein has strong water absorption, can cause rubber moisture absorption, mildew, insulation degradation, protein and increase heat generation shortcomings.

- Q: What are the applications of rubber airbags in the automotive field?

- Rubber accounts for 5% of the total weight of automotive materials, with an average of 100200 rubber parts per car, with a total number of 200500. Along with the automobile reliability, environmental protection and energy saving requirements continue to increase, and rubber materials, product structure optimization, improve the heat resistance, low temperature resistance, long aging, oil resistance, leakage resistance, long-term fatigue, and further reduce the cost has become the main topic of the development of automotive rubber. Fluorine rubber, silicone rubber, acrylic rubber and other special heat-resistant elastic body will still be the mainstream of the future direction of the development of automobile rubber.

- Q: Is sandal rubber bottom good or polyurethane good?

- Rubber material itself poor ventilation, long wearing easily lead to beriberi. And summer rains, if the rain does not drain, will add story.

- Q: What's the difference between silicone rubber and 703.704 glue?

- 704, temperature range of -50-250, better temperature effect, mainly used for sealing electric heating devices; electric plug sealing; instrument, instrument bonding and sealing.

- Q: Bought a mouse pad, a little rubber, how to remove?

- Rubber is a kind of deodorant used to remove or reduce the acid produced in the processing of all kinds of rubber or in the process of using the alkoxy compound, sulfide, vinyl compounds, ammonia, CO2 plastic smell of chemical additives, the smell if inhaled for a long time will stimulate the senses, give people uncomfortable feeling even harmful to the body two, produce pollution to the environment, the chemical composition of rubber and odor molecules produced and their composition and structure of the rubber is different, also uses other mechanisms, both deodorant rubber rubber itself, also want to consider a variety of additives such as odor curing agents released, the use of rubber deodorant to improve the rubber products the level of environmental protection, and improve the rubber production environment, is of great help for the comprehensive utilization of recycled rubber resources. Any of various forms of rubber, such as gas, powder, or liquid, usually used in accordance with odour and odor characteristics.

- Q: How are rubber wires processed?

- In the production of rubber products, vulcanization is the last process.Vulcanization is a crosslinking process in which rubber molecules change from linear structure to network structure under certain conditions. Curing methods are cold vulcanization, room temperature vulcanization and heat vulcanizing three kinds. Most rubber products are vulcanized by heat. Hot vulcanizing equipment, vulcanizing pot, flat vulcanizing machine, etc.. Rubber wires and cables are vulcanized by continuous hot air.

- Q: I do rubber products, I would like to ask what metal accessories are rubber products, the specific name is what, good, then points

- Silica gel tube, other rubber tube, clip fabric hose, braided hose, oil resistant hose, special hose, winding hose, industrial rubber, rubber products, insulating sleeve

- Q: Does the fuel pipe for automobiles belong to rubber products?

- If it is gasoline, remove the oil supply rack and the metal oil pipe on the chassis, to connect the need for some of the arc, are rubber material pipe.

- Q: What about rubber molding, foaming and layering?

- Foaming1 vulcanization is not sufficient, the temperature is too low or time is too short, so that the volatile compounds produced during curing have not been cleaned out;2, under the pressure of vulcanization, the trapped gas and sulfur volatile matter can not be discharged in time3, there is air or moisture in the glue;4, curing temperature is too high, the surface of the gum material premature vulcanization, hindered the glue material in the steam, air free precipitation5 vulcanization speed of material is too fast

Send your message to us

Auto Windshield Rubber Seal Strip for Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords