White PVC PU Conveyor Belt in Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

White PVC PU Conveyor Belt in Food Industry

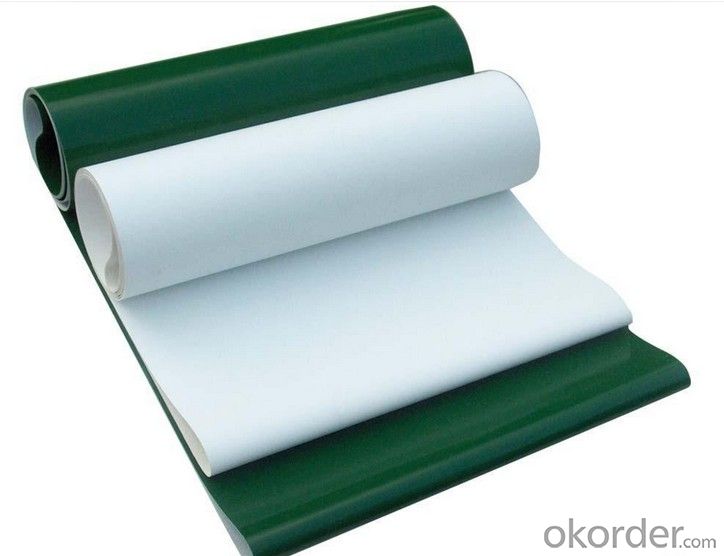

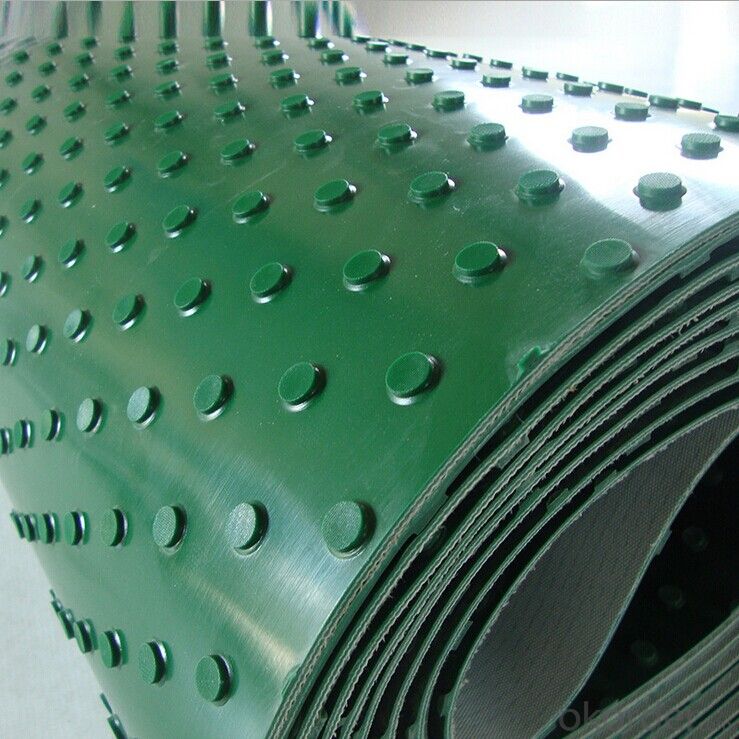

Descriptions of White PVC PU Conveyor Belt

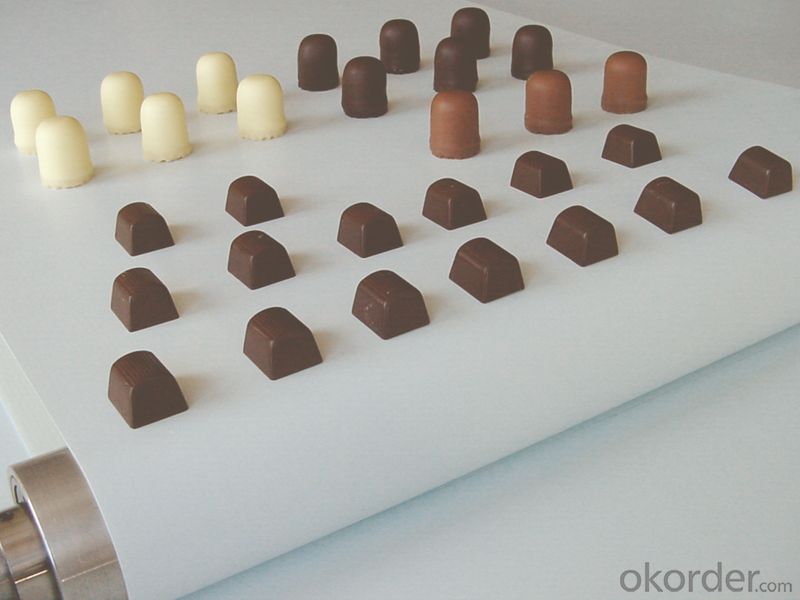

1.mainly used for granular materials bulk conveying ascension. Such chips, peanut, sweets, dried fruits, vegetables, frozen food, vegatables,chemical and other granular or block items.

2.Hoist hopper is made of food-grade polypropylene (PP)

3.with artistic looking

4.deformation difficult

5.resistance heat and cold

6.can be used as a continuous or batch-type weighing machine or packaging production line by connecting with other facilities

7.simple maintenance

8.disassembling easy

9.convenient cleaning

10.custom-made size

Application areas of White PVC PU Conveyor Belt

Office automation equipments

Medical equipment

Packaging machinery

Swimming pool cleaning robots

Plotters

Money changers

Optical instruments

Robotic arms

Electric appliances

Vacuum systems

Vending machines

Food machinery

Textile machinery

DIY equipments

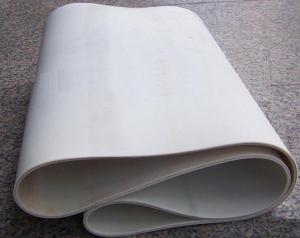

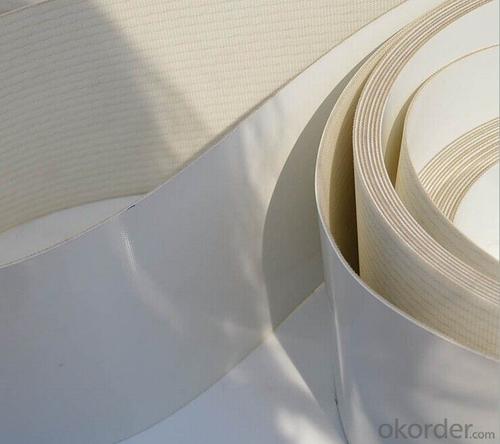

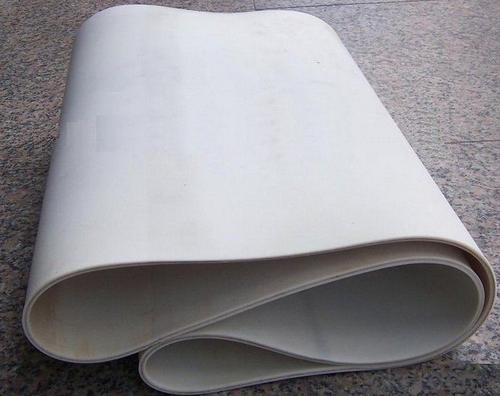

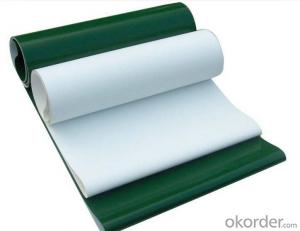

Pictures of PVC Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in

okorder.com. Okorder.com provides you the products with best price and quality!

- Q: How does rubber mobile phone cover change yellow?

- In physical properties, rubber has swelling, rheological properties and other changes. Tensile strength, elongation at break, impact strength, flexural strength, compression ratio and elasticity decrease.

- Q: Rubber soaked with hot water will not come out harmful substances?

- Chloroprene rubber chloroprene as the main raw material, made by homopolymerization or copolymerization of small amounts of other. Such as high tensile strength rubber, heat resistance and light resistance, aging resistance and oil resistance properties are superior to natural rubber, styrene butadiene rubber, butadiene rubber. It has a good flame resistance and excellent resistance to burning, its chemical stability is high, water resistance is good

- Q: How to test the abrasion resistance of rubber?

- As long as the amount of carbon black is added, the wear resistance will be increased. Have the Akron abrasion resistance test (the rubber disc shape small rubber wheels on the wheel rotating friction, turn a lap after the contrast test before and after the rubber wheel quality, poor quality of smaller, better resistance).

- Q: What is rubber material?

- The molecular chain of rubber can be crosslinked, and the crosslinked rubber can recover quickly when it is deformed by external force, and has good physical and mechanical properties and chemical stability. Rubber is the basic raw material of rubber industry. It is widely used in making tyres, rubber hoses, tapes, cables and other kinds of rubber products.

- Q: What are the ingredients in the tires?

- The tire carcass, is composed of a buffer layer (or belt), tread, sidewall and bead. Tyre section can be divided into several separate regions: crown area, shoulder area (tread slope), flex area (sidewall area), and strengthening the bead region.

- Q: How is rubber made? What kind of equipment do you need? How much is it?

- The main raw material is rubber, rubber products with various agents, as well as the fiber and metal skeleton material, the basic production process of rubber products including plastication, mixing, calendering, extrusion, molding, curing 6 basic processes.

- Q: What is the difference between natural and synthetic rubber?

- Natural rubber is one of synthetic rubber, and synthetic rubber can be divided into many kinds.

- Q: How can the rubber shoes be dyed?

- The rubber material of the shoe edge was stained with a soft brush gently on top with a little toothpaste. The fluoride contained in toothpaste is a good cleaning detergent.

- Q: What is rubber made of?

- High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

- Q: What about rubber molding, foaming and layering?

- Return the glue (the rubber has not been used up after heat treatmentThe glue and the new rubber are mixed together to heat up, and the remaining glue is called a return glue. When the mixture is mixed with the new rubber, the mixture is uneven and the degree of vulcanization is not uniform, resulting in delamination

Send your message to us

White PVC PU Conveyor Belt in Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords