Green PVC Food Conveyor Belt Light Duty PVC Belts

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Green PVC Food Conveyor Belt Light Duty PVC Belts

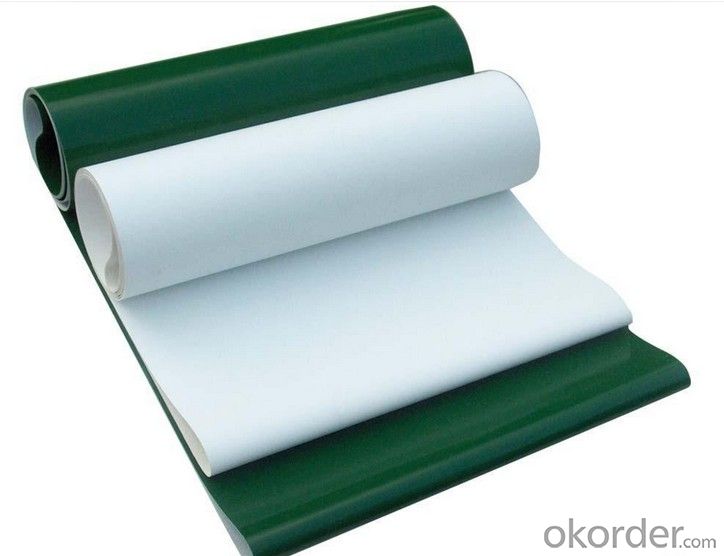

Descriptions of PVC Conveyor Belt

Characteristics:

It adopt high-intensity polyester filament and yarn weave as the whole core, and then is impregnated by the PVC.

Suitable for applications in dry conditions at a slope angle of no greater than 16 degrees.

Cover thickness can be from 0.5 to 4 mm.

Standard Ranges

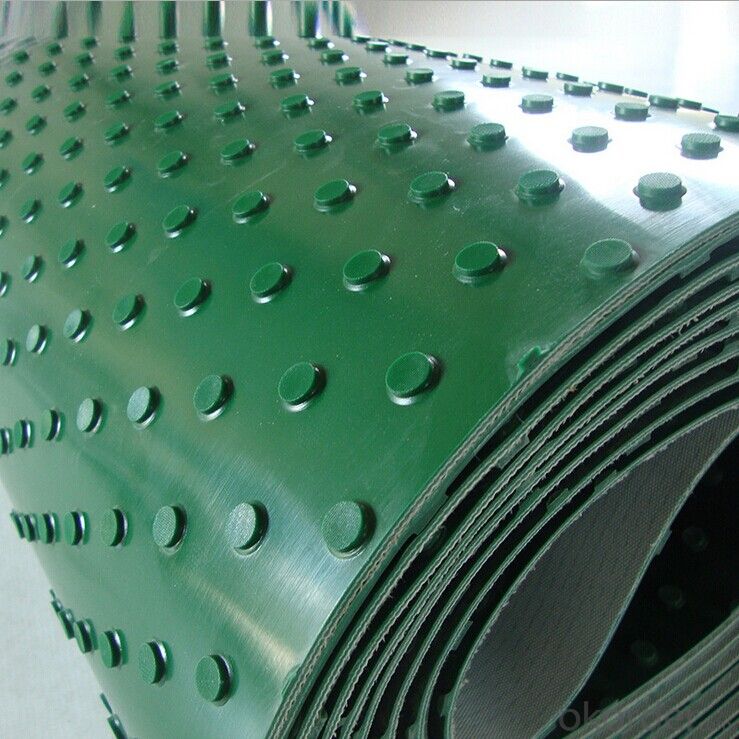

We have more than 100 types of belt and a wide range of belt accessories.

Special belts can also be manufactured complete with

1) Guides, profiles and sidewalls fitted by means of high frequency or hot air welding machines.

2)Curved or Corner conveyor belts it allows the solving of logistic problems through the deviation of the conveying system from a few degrees to a 180°C turn.

3)Belts can be made endless, spliced or with prepared ends for on-site splicing to be done with dedicated Adhesives.

Features of PVC Conveyor Belt

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise (LdB belts)

* Working temperature ranges from -10 to 80Deg.C

Applications

Airports

Postal automation

Parcel handling

Treadmills

Packaging and wrapping

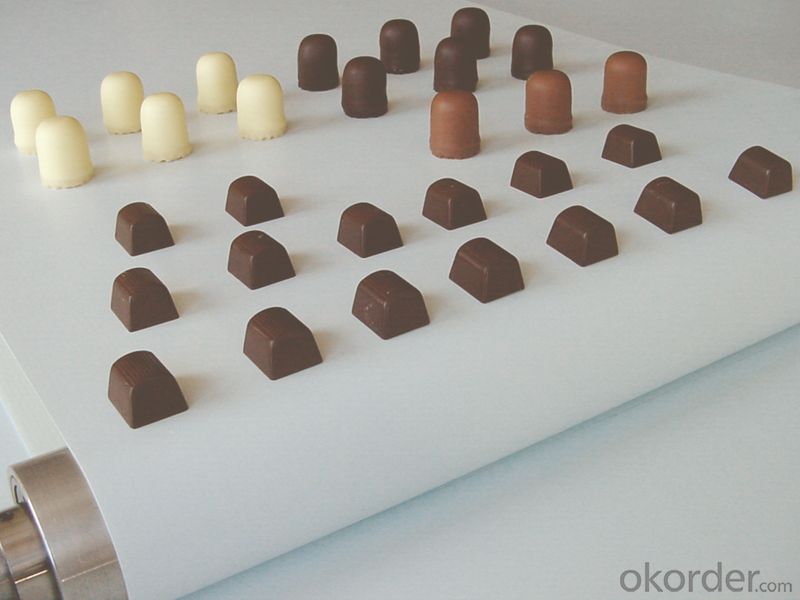

Confectionery Industry

Food Processing Industry

Paper Printing Industry

Pictures of PVC Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in

okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What are the uses of ethylene propylene rubber?

- Because of the high strength, good flexibility, high gloss and easy recycling of thermoplastic three yuan EPDM rubber, EPDM/PP has been used as the main material in automobile bumpers and automobile dashboard production both at home and abroad. It is estimated that only two items of bumper and dashboard will be used in 2010, and the annual domestic consumption of EPDM/PP can reach 45 thousand tons. The main processes adopted for the recycling of these products are: first remove the coating of the product surface - grinding - Cleaning - re granulation - adding new materials to produce new products. Thus, a large amount of raw material can be saved and better economic benefits can be obtained in the production of the bumper and the dashboard. The ethylene propylene rubber used in the automotive industry accounts for 42%-44% of the total ethylene propylene rubber in China, excluding the ethylene propylene rubber used by ships, trains and container seals. Because the bonding properties of EPDM rubber is not good, in the tire industry in a large number of materials of tire body and the tread part to promote the use of ethylene propylene rubber, only in the inner tube, white wall, tire strip and other parts of the use of a small amount of ethylene propylene rubber.

- Q: What does the rubber tire do to people?

- Rubber is an elastic polymer. Rubber can be obtained from the plant sap, can also be man-made, both have many applications and products, such as tires, washers, etc., has become an important economic crop. The cultivation of rubber is mainly concentrated in Southeast Asia, such as Thailand, Malaysia and Indonesia.

- Q: Is sandal rubber bottom good or polyurethane good?

- Rubber material itself poor ventilation, long wearing easily lead to beriberi. And summer rains, if the rain does not drain, will add story.

- Q: Process for producing rubber products

- The 1. main raw materials of rubber products with rubber as basic material, and rubber is grown in tropical, subtropical and the rubber tree bark collected by artificial cut.2. various compounding agents are auxiliary materials used to improve some properties of rubber products.3. fiber material (cotton, linen, wool and all kinds of man-made fiber, synthetic fiber and metal materials, steel wire) is used as rubber products skeleton material, in order to enhance the mechanical strength, limit product variant. In the preparation of raw materials, the ingredients must be accurately weighed according to the formula. In order to make the rubber and the complexing agent can mutually mixing, need to process material. Rubber to 60--70 C drying room drying soft gel, gel breaking and then cut into small pieces, with a massive agent. Such as wax, stearic acid, rosin and so on to be crushed. If the powder containing mechanical impurities or coarse screening to remove liquid such as pine tar, ancient Malone needs heating, melting, evaporation and filter impurities, complexing agent to dry or easy to agglomerate, when mixing if not dispersed vulcanized bubbles will affect the quality of the products

- Q: What's the difference between silicone rubber and 703.704 glue?

- 704, temperature range of -50-250, better temperature effect, mainly used for sealing electric heating devices; electric plug sealing; instrument, instrument bonding and sealing.

- Q: What kind of materials should be used for rubber products to keep the brightness of the mirror for a long time?

- It is important to use recycled material as a high light material. If the selected material is not available, then it is not effective. It must be pure, only ABS.PMMA, or PC/ABS. There is material, it is best not to contain white material, mottled with a little transparent, is the best.

- Q: What is the composition of the vulcanizing agent for silica gel?

- Vulcanizing agent is organic peroxide, or bridging agent, used for curing silicone rubber (Xi Likang), EVA and curing of unsaturated polyester.

- Q: What are the causes of the rubber products breach?

- It's aging of rubberAging refers to the polymer materials (including rubber, plastics, fiber and so on) in the processing, storage and use of the process, due to the comprehensive effect of internal and external factors, its performance gradually deteriorated, resulting in the final loss of use value.

- Q: How can I get rid of the rubber?

- You smell the smell from the vulcanized rubber residues, not much of the flavor is generally placed in a cool ventilated place, you can, and if the smell is large, you can use rubber deodorant, supermarkets generally sell

- Q: What is the rubber composition and function of the airplane tyres?

- Polybutadiene rubber is prepared by the solution polymerization of butadiene butadiene rubber, with excellent cold resistance, abrasion resistance and flexibility, but also has good anti-aging properties. Polybutadiene rubber is mostly used in the production of tires, a small part for manufacturing cold products, cushioning materials and belt and rubber shoes. Butadiene rubber drawback is the tear resistance of the cross, wet skid resistance is not good. Isoprene rubber is the abbreviation of polyisoprene rubber. It is produced by solution polymerization. Isoprene rubber, like natural rubber, has good elasticity and wear resistance, excellent heat resistance and good chemical stability. Isoprene rubber (not before processing) strength was significantly lower than that of natural rubber, but the quality uniformity, processing performance is better than natural rubber. Isoprene rubber can be used instead of natural rubber to make heavy-duty and off-road tires, and can also be used to produce all kinds of rubber products.

Send your message to us

Green PVC Food Conveyor Belt Light Duty PVC Belts

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords