Polyamide Nylon Flat Transmission Belt Textile Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Polyamide Nylon Flat Transmission Belt Textile Industry

Nylon Transmission Belt

1.Polyamide flat belt

2.largest width is 500mm;

3.Thickness:1.0mm-5.0mm

4.High efficiency low elongation

5.Flexible high fatigue resistance

6.Good antistatic performance

7.Stable friction coefficient

Application

Widely used in Machinery, textile, printing and dyeing, woodworking machinery, packaging, printing, post and telecommunications, food, stone, metal processing, logistics, tobacco industry

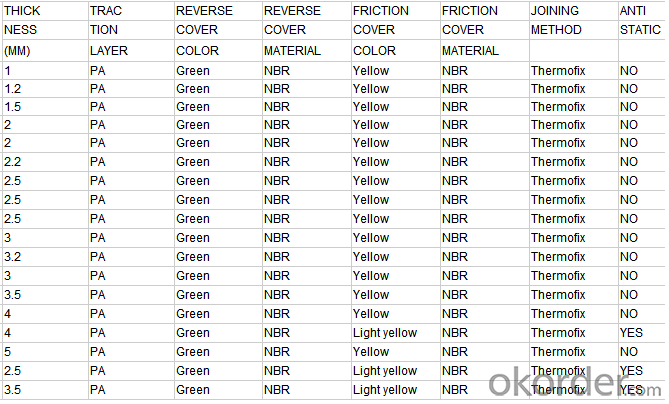

Specifications

Advantage

1. Good elasticity, anti-impact

2. High adhesion, good flexing capacity

3. Stable transmission

4.Good antistatic performance

5. Good resistance to moisture and heat, corrosion resistant

6. Good wear ability and long service life

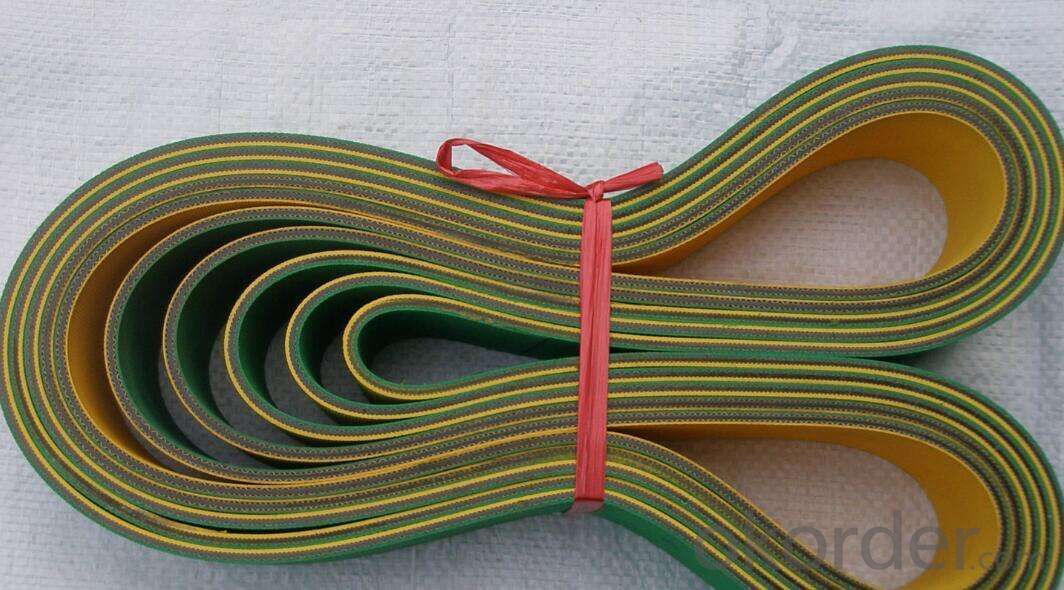

Flat Transmission Belt Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the Flat Transmission Belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: Silicone is silicone rubber? Extracted from there?

- Generally speaking, silica gel can be divided into two categories: organic silica gel and inorganic silica gel according to their properties and components. According to its composition, it is divided into extruded silica gel and molded silica gel.

- Q: How to distinguish between good and bad silicone rubber gasket?

- Hardness and elongation stress reflect the rigid (stiffness) index of rubber material, and they are the necessary force for silica gel products to produce certain deformation. It is also a way to distinguish the quality of silica gel products.

- Q: What plastic rubber will not be subjected to oil (such as transformer oil) by quality (e.g., aging, dissolution)?

- Generally, aging and dissolution occur. If you want to make the structure, you can choose XF POM C13031 Ticona of the company. This is the company specializing in the development of temperature resistance, oil (especially gasoline, diesel) products.

- Q: What is the relationship between the hardness and tensile strength of rubber pad?

- The relationship between the hardness and tensile strength of rubber pad: the higher the hardness, the greater the tensile strength.

- Q: What kind of product is suitable for rubber trimmer? Where's the rubber trimmer?

- Trimming machines are mainly used in wood chamfering, metal trimming, strip grinding and other motor type movable trimming equipment. Chamfering machine.Stationary trimmerGenerally used for metal strip trimming, that is, after the strip of metal strips with a fixed tool to remove burr or chamfer on both sides of the required radian,Scope of application: used in tableware, stationery, hardware, sheet metal and other special equipment industry.

- Q: What's wrong with rubber whitening?

- White: may refer to spray frost (dissolved in more than rubber, drugs in rubber migration to the rubber surface), 1 reasons, excessive drug formulation; 2, sulfur is not complete, the two plus sulfur solution (130 - to 1 hour);It may be a white filler in rubber, so there's no way out. It's only the formula;

- Q: Natural rubber, general rubber, synthetic rubber. Are these all rubber products?

- Like you said, natural rubber, synthetic rubber, synthetic rubber, these are all kinds of rubber, not products. Rubber products refer to products that can be used directly! And natural rubber, synthetic rubber, general rubber, these are only raw materials, to be processed into products.

- Q: What kind of material does the shockproof rubber cushion usually choose? What's the hardness?

- Of course is to choose butadiene rubberThe biggest characteristic is the molecular structure, mainly for the CIS structure, so the elasticity, cracking resistance and dynamic performance is excellent, and the rubber pad shock proof function is guaranteed, and the rubber cushion life is guaranteed, and the hardness is about 55.

- Q: What is the rubber composition of sole?

- The sole of high pressure polyethylene and rubber flavor, rubber and plastic used together.Student: Rubber soled heavy, expensive, not resistant to oil, heat. Variable color.

- Q: What is the rubber composition and function of the airplane tyres?

- Ethylene propylene rubber and ethylene propylene rubber are synthesized with ethylene and propylene as main raw materials. They are resistant to aging, electrical insulation and ozone resistance. Ethylene propylene rubber can be filled with oil and filled with carbon black. The price of the product is low, and the chemical stability of the ethylene propylene rubber is good. The abrasion resistance, elasticity, oil resistance and the proximity of styrene butadiene rubber are close. Ethylene propylene rubber is widely used. It can be used as tyre, sidewall, rubber strip and inner tube, as well as parts of automobile. It can also be used as wire, cable sheath and high voltage and extra high voltage insulating material. Can also manufacture rubber shoes, sanitary products and other light colored products. It is a chloroprene rubber as the main raw material, made by homopolymerization or copolymerization of small amounts of other. Such as high tensile strength, heat resistance, light resistance, aging resistance and oil resistance properties are superior to natural rubber, styrene butadiene rubber, butadiene rubber. It has a good flame resistance and excellent resistance to burning, its chemical stability is high, water resistance is good. Chloroprene rubber is electrical insulation, cold resistant performance is poor, rubber is not stable in storage. Neoprene is widely used, such as the manufacture of transport belts and belts, wires and cables, and the manufacture of oil resistant hoses, gaskets, and chemical resistant equipment linings.

Send your message to us

Polyamide Nylon Flat Transmission Belt Textile Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords