Flat Nylon Transmission Belts for Textile Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Industrial Power Nylon Flat Transmission Belt

Application

Widely used in Machinery, textile, printing and dyeing, woodworking machinery, packaging, printing, post and telecommunications, food, stone, metal processing, logistics, tobacco industry

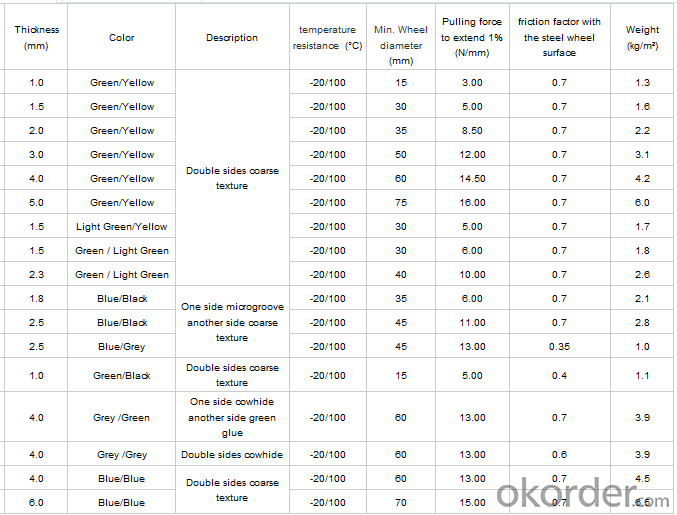

Specifications

Advantage

1. Good elasticity, anti-impact

2. High adhesion, good flexing capacity

3. Stable transmission

4.Good antistatic performance

5. Good resistance to moisture and heat, corrosion resistant

6. Good wear ability and long service life

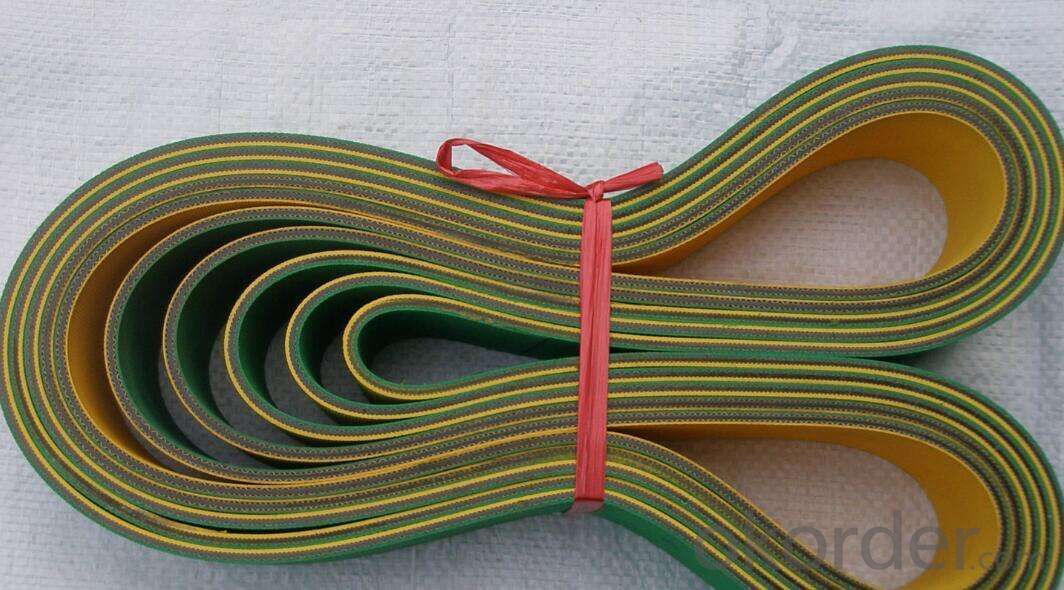

Flat Transmission Belt Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the Flat Transmission Belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What is the role of softening plasticizers in rubber? How are they classified?

- The plasticizer used in the production process should meet the following conditions: good plasticizing effect, low dosage, quick absorption, good compatibility with rubber, low volatility, no migration, cold resistance, water resistance, oil and solvent resistance, heat resistance, light resistance, good insulation, good flame resistance resistant bacteria, colorless, non-toxic, cheap and so on.But in fact, it is impossible to fully satisfy the above-mentioned conditions of plasticizers. Therefore, in actual use, more than two or more kinds of plasticizers mixed use, in order to make up for each other, where the amount of commonly known as the main plasticizer, and the other called auxiliary plasticizer.

- Q: When rubber products are hardened, what methods soften?

- The rubber is softened by soaking in the solvent, but it will damage the original physical and chemical properties of rubber!

- Q: Why do rubber products Blister?

- Foaming reasons of rubber products:1 vulcanization is not sufficient, the temperature is too low or time is too short, so that the volatile compounds produced during curing have not been cleaned out;2, the vulcanizing pressure is insufficient, the detained gas and sulfur volatile matter can not be discharged in time.3, there is air or moisture in the glue;4, curing temperature is too high, the surface of the gum material premature vulcanization, hindered the rubber material in the steam, air free precipitation.

- Q: What's the difference between silicone rubber and 703.704 glue?

- 704, temperature range of -50-250, better temperature effect, mainly used for sealing electric heating devices; electric plug sealing; instrument, instrument bonding and sealing.

- Q: How to test the abrasion resistance of rubber?

- It is mainly divided into two kinds of natural rubber and synthetic rubber. Natural rubber is made from rubber, rubber and grass. Synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life. It has a wide range of uses. [1] can also be divided into rubber with natural rubber, general rubber, styrene butadiene rubber, nitrile rubber, silicone rubber, butadiene rubber, butyl rubber, EPDM rubber, chloroprene rubber types.

- Q: How to make white rubber products do not yellow or delay yellowing time?

- 1, raw material itself yellow degeneration, for example, NR aging resistance than SBR and BR difference.2, the matching of accelerant system. The accelerator can use DM and M to achieve yellow change 4, but the whole system needs to be adjusted. The use of anti yellowing enhancers such as two dithiocarbamate on yellow Bianyou benefits, but at the expense of great property and operation. The faster the sulfidation rate, the less the chance of breaking the chain, and the aging degree is restrained. But at the same time sacrificing the comprehensive nature. The cross-linking bonds generated by rapid vulcanization and slow vulcanization are different. For example, tension, tear and so on, are greatly affected. But the elasticity brittleness will increase.

- Q: What's wrong with rubber whitening?

- Rubber whitening (spray cream) the main reason for analysis, rubber spray cream, including rubber surface spray and surface spray cream. Spray (Bloom) is a phenomenon in which liquid or solid agents migrate from rubber to rubber surfaces [1]. It can be seen that the inner compound of rubber will precipitate and form a spray. There are three kinds of forms of rubber spray. Powder spraying, wax injection, injection (also known as exudation).1. powder is a curing agent, accelerator, activator, antioxidant and filler powder with precipitation agent on the rubber surface, and form a layer of powder.2. spray wax is paraffin wax, ceresin wax precipitation etc. on the rubber surface, forming a layer of wax.3. fuel injection is softening agent, tackifier, lubricants, plasticizers and other additives in liquid precipitation of the rubber surface, and form a layer of oil.In practice, frost forms on rubber surfaces sometimes appear in one form, sometimes in two or three forms.

- Q: Can the rubber surface be painted with paint?

- Rubber surface painting, rubber will have an impact on the long time will crack!

- Q: What's the difference between a rubber track and a plastic runway? Or is it just a thing, really answer?

- Plastic: plastic runway is mainly composed of carbon, hydrogen and oxygen, nitrogen and other organic or inorganic elements, the finished product is solid, in the manufacturing process is molten liquid, so can take heating to melting, the pressure makes the flow, cooling the solidification, and the formation of various shapes, this huge while the group known as the plastic material be the most changeful.

- Q: What does rubber mean?

- High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers.

Send your message to us

Flat Nylon Transmission Belts for Textile Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords