Waterproof Rubber Seal Strip with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Waterproof Rubber Seal Strip with High Quality:

1. Brief Description of Waterproof Rubber Seal Strip with High Quality

We produce rubber seal strip according to customer's requirements, samples, or 2D,3D drawing, any format. If you are interested in our factory please do not hesitate to ask for a similar one or OEM&ODM made.

2. Main Features of Waterproof Rubber Seal Strip with High Quality

1).Environmental safety, good insulation, high temperature, low compression set, strong resilience;

2).smooth surface, uniform density foam;

3).acid, anti-aging, non-toxic;

4).good non-stick surface, good air permeability;

5).using 100 percent high-quality rubber raw materials, and rigorous testing

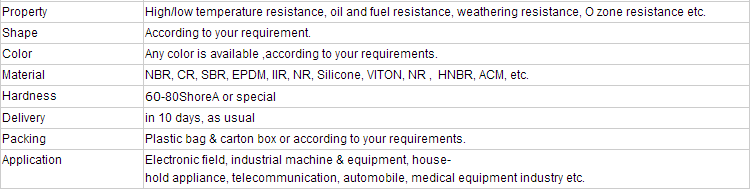

3. Main Specification of Waterproof Rubber Seal Strip with High Quality

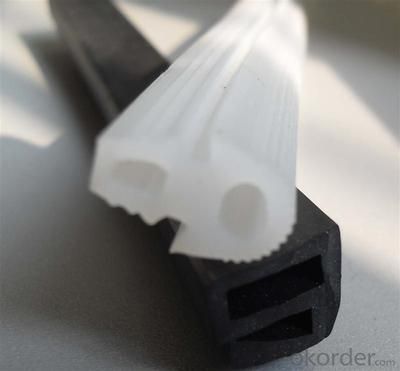

4. Pictures of Waterproof Rubber Seal Strip with High Quality

5. FAQ

1.Q: Do you produce standard parts?

A: No, We do non-standard parts only, customised parts, OEM. According to customers design, drawing or samples.

2. Q: Your MOQ?

A: We do even prototype. No MOQ, or we can say, MOQ is 1pc.

3. Q: Your Product life time?

A: Usually, rubber seal strips can be used about 10 years.

4. Q: Your Product making time?

A: Usually, within 30 days. According to the quantity,we may refund the R$D spendings

5. Q: Your sample lead time?

A: Usually 10 - 15 days after mould's done.

6. Q: Your paymet terms?

A: We accept T/T, L/C, Paypal, Escrow, Western union, Money gram, D/P, D/A, Cash, and O/A.

- Q: How do rubber undergo vulcanization?

- In the process of hot vulcanization, the general temperature is 10 degrees higher, and the curing time is shortened by about half. Rubber is a bad conductor of heat, which can easily cause uneven vulcanization.

- Q: Properties and specific uses of various rubbers

- Rubber is divided into natural rubber and synthetic rubber. Natural rubber is mainly derived from the Hevea tree. When the epidermis of this rubber tree is cut open, it will shed milky juice. It is called latex, and the latex will be natural rubber when it is condensed, washed, molded and dried. Rubber productsSynthetic rubber is made by synthetic methods, and different kinds of rubber can be synthesized with different raw materials (monomers). Such as, butadiene rubber, chloroprene rubber, styrene butadiene rubber and so on. The yield of synthetic rubber has greatly exceeded that of natural rubber, of which the largest yield is styrene butadiene rubber.

- Q: How to remove the peculiar smell of rubber products?

- The general method is to add some flavor spices used to degrade or reduce all kinds of rubber produced in the processing or use process in acids, alkoxy compound such as smell, method is effective, but not fundamentally solve the problem.

- Q: What is the relationship between the hardness and tensile strength of rubber pad?

- The molecular weight increases, increasing the fan Edward force, the chain segment is not easy to slip, the equivalent of molecules formed between physical crosslinking points with the molecular weight increased, the tensile strength increased to a certain extent reached equilibrium; the microstructure of the molecule, such as the effect of CIS and trans type structure; crystallization and orientation.

- Q: Half finished rubber film surface white is going on

- Because inside the rubber compounding agent reachsupersaturation, rubber compounding agent near surface precipitates first, then from the inner to the surface migration of precipitation when complexing agent in the rubber to reduce its saturated state, precipitation process ended. Causes the complexing agent to achieve the supersaturation state, causes the rubber spraying frost the main reason to have: the rubber formula design is improper, the craft operation is not proper, the raw material quality fluctuates, the storage condition is poor, the product owes sulfur, the product aging and so on.

- Q: What is food grade natural rubber?

- Is mainly made of natural rubber, made of natural rubber products, through the relevant national food contact using rubber testing standards, to reach the food grade.

- Q: What are the hazards of waste rubber and how can they be used for regeneration?

- Every year, millions of tons of waste rubber are produced in the world, and the quantity is so huge. How to deal with them effectively has become a common concern of the whole society.

- Q: How can rubber be made into rubber when it is made?

- Just cut off the rubber is not available, belongs to the first rubber, according to the products and the use of working conditions to set the formula, made of mixed rubber, vulcanized on the vulcanization machine with mold has been good, curing after trimming, testing, packaging. The required rubber products will be ready.The process flow of the production process is:Raw material preparation, plasticization, blending, molding, vulcanizing, cleaning and testing

- Q: PVC conveyor belts and rubber belts differ from each other in their respective advantages

- PVC is actually a vinyl polymerization substance, whose material is a non crystalline material. PVC materials often use stabilizers, lubricants, auxiliary processing agents, pigments, anti shock agents and other additives in practical use. Is not flammable, high strength, excellent resistance to climate variability and geometric stability. PVC has strong resistance to oxidizing agents, reducing agents and strong acids. However, it can be corroded by concentrated oxidizing acids such as concentrated sulfuric acid and concentrated nitric acid, and it is also not suitable for contact with aromatic hydrocarbons and chlorinated hydrocarbons.

- Q: There is a crack in rubber products

- The additive time temperature and pressure of semi-finished shapes semi-finished semi-finished products placed as far as possible when placed speed gap semi-finished size can be more appropriate to put five percent to ten percent semi finished mixing can put some help curing

Send your message to us

Waterproof Rubber Seal Strip with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords