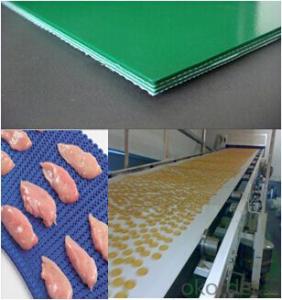

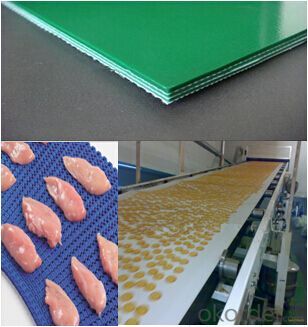

ISO Standard PVC Flat Conveyor Belt PVC Green Belt Conveyor

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ISO Standard PVC Flat Conveyor Belt PVC Green Belt Conveyor

Specifications

Anti-static and tearing resistant

Abrasion and oil/heat/fire resistant

Working temperature ranges from -10 to 80Deg.C

With advanced coating machine and other excellent facilities, we are professionally producing PVC&PU light conveyor belts, which are extremely suitable for light industry such as beer industry, paper making industry, food industry, textile industry etc.

Product Feature

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise

* Working temperature ranges from -10 to 80Deg.C

| code | Top cover | Bottom Cover | Thick | Characteristics | Fabrics | ||||

| Material | Colour | Surface | Material | Colour | Surface | mm | Plies | ||

| PVC conveyor belt | |||||||||

1/10 S/P W | PVC | White | Smooth | - | Natural | Fabric | 1.0 | Antistatic | 1 |

1/12 S/S BK | PVC | Black | Smooth | PVC | Black | Smooth | 1.2 | 1 | |

1/16 D/STF BK TM | PVC | Black | Diamond | - | Natural | Strong Fabric | 1.6 | Tread mill | 1 |

2/12 P/P W | Fabric | Natural | Fabric | Fabric | Natural | Fabric | 1.2 | Antistatic | 2 |

2/18 P/P W | Fabric | White | Fabric | - | Natural | Fabric | 1.8 | Antistatic | 2 |

2/20 D/P AG | PVC | Apple Green | Diamond | - | Natural | Fabric | 2.0 | Antistatic | 2 |

2/2O S/P AG | PVC | Apple Green | Smooth | - | Natural | Fabric | 2.0 | Antistatic | 2 |

2/20 S/P PG | PVC | Petrol Green | Smooth | - | Natural | Fabric | 2.0 | No-antistic | 2 |

2/20 M/P BK | PVC | Black | Matt | - | Natural | Fabric | 2.0 | Antistatic | 2 |

2/20 S/P W FDA | PVC | White | Smooth | - | Natural | Fabric | 2.0 | FDA | 2 |

2/20 S/P W | PVC | White | Smooth | - | Natural | Fabric | 2.0 | 2 | |

2/20 S/P BK | PVC | Black | Smooth | - | Natural | Fabric | 2.0 | 2 | |

2/25 S/P W FDA | PVC | White | Smooth | - | Natural | Fabric | 2.5 | FDA | 2 |

2/30 S/FF PG | PVC | Petrol Green | Smooth | - | Natural | Flexible Fabric | 3.0 | Cold-Resistant | 2 |

2/30 S/P W FDA | PVC | White | Smooth | - | Natural | Fabric | 3.0 | FDA | 2 |

2/30 S/P AG | PVC | Apple Green | Smooth | - | Natural | Fabric | 3.0 | Antistatic | 2 |

2/30 LR/SF AG | PVC | Apple Green | Longitudinal Lib | - | Natural | Silent Fabric | 3.0 | 2 | |

2/30 S/D W FDA | PVC | White | Smooth | PVC | White | Diamond | 3.0 | FDA | 2 |

2/30 S/D W | PVC | White | Smooth | PVC | White | Diamond | 3.0 | 2 | |

2/30 S/D AG | PVC | Apple Green | Smooth | PVC | Apple Green | Diamond | 3.0 | Antistatic | 2 |

2/38 S/P W | PVC | White | Smooth | - | Natural | Fabric | 3.8 | 2 | |

2/46 TS/P AG | PVC | Apple Green | Saw Tooth | - | Natural | Fabric | 4.6 | Antistatic | 2 |

2/50 RT/P AG | PVC | Apple Green | Rough Top1 | - | Natural | Fabric | 5.0 | No-antistic | 2 |

3/30 C/C W | Cotton | Natural | Cotton | Cotton | Natural | Cotton | 3.0 | 2ply cotton 1ply fabric | 3 |

3/40 S/P TAN | PVC | TAN Colour | Smooth | - | Natural | Fabric | 4.0 | No-antistic | 3 |

3/50 S/D AG | PVC | Apple Green | Smooth | PVC | Apple Green | Diamond | 5.0 | Antistatic | 3 |

3/40 S/P W FDA | PVC | White | Smooth | - | Natural | Fabric | 4.0 | FDA | 3 |

| PU conveyor belt | |||||||||

1/08 S/P W U FDA | PU | White | Smooth | - | Natural | Impreg-nated | 0.8 | Antistatic | 1 |

2/15 M/P W U FDA | PU | White | Matt | - | Natural | Impreg-nated | 1.5 | Antistatic | 2 |

2/14 M/P PG U FDA | PU | Petrol Green | Matt | - | Natural | Impreg-nated | 1.4 | Antistatic | 2 |

2/21 S/P W U FDA | PU | White | Smooth | - | Natural | Fabric | 2.1 | Antistatic | 2 |

2/21 S/P W U KE | PU | White | Smooth | - | Natural | Fabric | 2.1 | Knife Edge Application | 2 |

2/30 S/P

W U FDA | PU | White | Smooth | - | Natural | Fabric | 3.0 | Antistatic | 2 |

Pls contact me freely if any inquiry or questions,thank you!

- Q: Rubber Mooney value is what meaning, what is the role of

- In accordance with the provisions of the standard GB 1232 (Mooney viscosity), rotation expressed by the symbol Z100 C 1+4. Where Z rotational viscosity; 1, preheating time is 1min; 4 - rotation time is 4min; 100 C - test temperature of 100 degrees.In our country, usually with ML100 or MS100 1+4 to 1+4 DEG C said. M said L Mooney, represented by the greater trochanter, S said with a small rotor.1 preheat for 1 minutes, 4 said that the test for 4 minutes. The larger the value of Mooney viscosity, said, the plastic is widely used as a low. Index control process performance of rubber.

- Q: What is the lowest cost material for the synthesis of rubber?

- Poly propylene rubber is synthetic materials, he is a kind of synthetic rubber, with ethylene propylene copolymer rubber basic monomer, divided into two EPDM (EPM) and three EPDM (EPDM) two categories;

- Q: Can rubber products be injection molded and plastic injection functions?

- Rubber is an elastic polymer. Rubber can be obtained from the plant sap, can also be man-made, both have many applications and products, such as tires, washers, etc., has become an important economic crop. The cultivation of rubber is mainly concentrated in Southeast Asia, such as Thailand, Malaysia and Indonesia.

- Q: Half finished rubber film surface white is going on

- Rubber is a latex made from rubber, tree, rubber, and grass. It is made of flexible, insulating, impermeable and air. High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

- Q: How do ordinary NBR and EPDM materials differ?

- Difference: EPDM density is lower than NBR, the appearance of EPDM is transparent or white, and NBR is yellow or white yellow.

- Q: Is rubber flame retardant?

- Rubber itself is flammable, in the production process can be filled with some flame retardant material, it can reduce its flammability, but at the same time reduce its inherent good performance, such as abrasion resistance, elasticity, etc..

- Q: What is rubber made of?

- High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

- Q: Why does rubber stink?

- The word "rubber" comes from the Indian language "cau-uchu", meaning "weeping tree"". Natural rubber is flowing out from the Hevea latex when tapping after solidification and drying process. In 1770, British chemist J. Priestley discovered that rubber could be used to erase pencil writing. The material used at that time was called rubber, which has been used so far. The molecular chain of rubber can be crosslinked, and the crosslinked rubber can recover quickly when it is deformed by external force, and has good physical and mechanical properties and chemical stability. Rubber is the basic raw material of rubber industry. It is widely used in making tyres, rubber hoses, tapes, cables and other kinds of rubber products.

- Q: What is food grade natural rubber?

- Is mainly made of natural rubber, made of natural rubber products, through the relevant national food contact using rubber testing standards, to reach the food grade.

- Q: How do you remove the rubber on your new slippers?

- There must be some rubber smell, because the bottom containing rubber and plastic bags are used as fine without air so the rubber flavor will be heavier, and you wear for a period of time will not fall, or to buy after put in place of ventilation blowing for one or two days no taste.

Send your message to us

ISO Standard PVC Flat Conveyor Belt PVC Green Belt Conveyor

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords