Color glazed steel sheet with cheap steel prices

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 35234 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

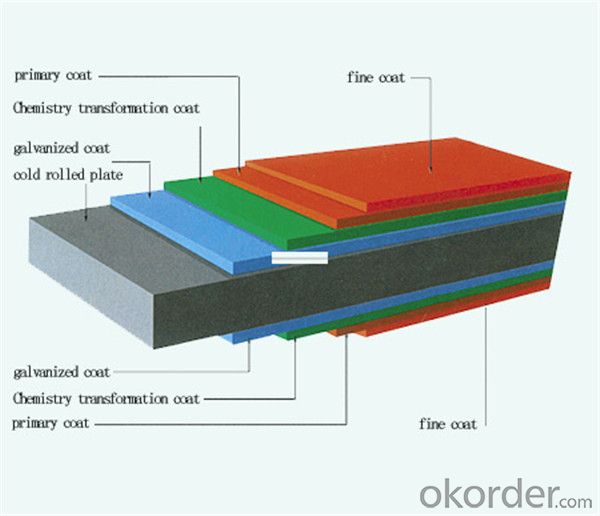

Pre-Painted Galvanised Steel (PPGI) is a metallic coated steel product with improved

corrosion resistance where the premium range PPGI also include features such as dirt

staining resistance, color retention, scratch resistance (ScratchCore™) and solar reflectance

(HeatBounce™). PPGI is commonly used in building materials such as roofing, cladding, walling, and etc.

Colors

All types of colors available as per RAL codes mainly White, Red, Blue, Green, Cream, Orange and various others.

Applications

Building industry, profiling, corrugation, furniture making, sign boards and for sandwich panels.

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

| ||||

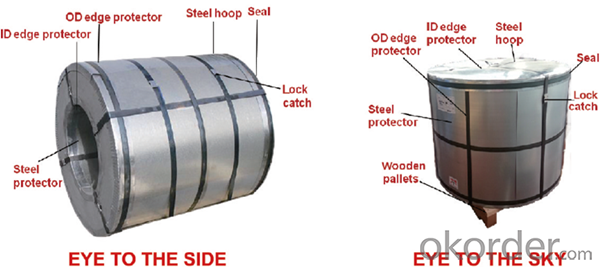

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link

from raw material to final product we have strict quality test;We resolutely put an end to

unqualified products flowing into the market. At the same time, we will provide necessary

follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange

the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but

the shipment will depend on the vessel situation

- Q: Can steel sheets be used for interior design purposes?

- Yes, steel sheets can be used for interior design purposes. They are commonly used for creating modern and industrial aesthetics in interior spaces. Steel sheets can be used for various applications such as wall paneling, room dividers, countertops, backsplashes, and decorative accents. Their durability, sleek appearance, and ability to be customized make them a popular choice for contemporary interior designs.

- Q: Can steel sheets be used for insulation cladding?

- Typically, insulation cladding does not involve the use of steel sheets. Instead, materials like foam boards, mineral wool, or fiberglass are commonly chosen for their thermal insulation properties. These materials are effective in minimizing heat transfer and enhancing energy efficiency. Conversely, steel sheets are more frequently utilized for structural purposes or as a protective layer owing to their robustness and durability. Though steel sheets can offer some protection, they lack the requisite insulation properties required to effectively prevent the transfer of heat or cold. Consequently, it is advisable to employ suitable insulation materials specifically designed for cladding purposes.

- Q: How to choose welding method for welding different plate and thick steel plate?

- For welding efficiency:General welding or argon arc welding of thin plate, medium plate with gas shielded welding (such as two welding), thick plate with submerged arc welding (usually not groove, single-sided, once the penetration of up to 20mm).

- Q: How do steel sheets compare to other materials like aluminum or plastic?

- Steel sheets have several advantages over other materials like aluminum or plastic. Firstly, steel is much stronger and more durable than both aluminum and plastic. It has a higher tensile strength and can withstand much greater loads and impacts. This makes steel sheets more suitable for applications that require high strength and structural integrity, such as construction, automotive, and aerospace industries. Secondly, steel is more resistant to extreme temperatures and fire compared to aluminum or plastic. Steel sheets have a higher melting point, making them less likely to deform or lose their structural integrity under high temperatures. This makes steel sheets ideal for applications that involve exposure to heat or fire, such as industrial furnaces or fire-resistant structures. Furthermore, steel sheets offer better corrosion resistance than aluminum or plastic. Steel can be coated with various protective layers like zinc or paint to prevent rusting and corrosion. Aluminum, on the other hand, is prone to corrosion in certain environments. Plastic, although generally resistant to corrosion, may degrade and become brittle over time. Therefore, steel sheets are a more reliable choice in applications where exposure to moisture or corrosive substances is a concern, such as marine environments or chemical processing plants. Lastly, steel sheets are more environmentally friendly than both aluminum and plastic. Steel is a recyclable material and can be reused indefinitely without losing its properties. Aluminum recycling requires significantly more energy, and plastic is known to have a detrimental impact on the environment due to its slow decomposition. Steel sheets, being recyclable and sustainable, are a preferred choice for those seeking environmentally friendly options. In conclusion, steel sheets outperform materials like aluminum or plastic in terms of strength, durability, resistance to extreme temperatures and corrosion, as well as being more environmentally friendly. However, the specific choice of material ultimately depends on the application requirements, cost considerations, and other factors.

- Q: Are steel sheets suitable for aerospace applications?

- Indeed, steel sheets prove to be a suitable option for aerospace applications. Renowned for its remarkable strength and durability, steel emerges as an outstanding preference for aircraft structural components. Its capacity to withstand impact and fatigue proves pivotal in the aerospace sector. Moreover, steel sheets can be effortlessly molded and joined through welding, facilitating the crafting of intricate forms and structures. Nevertheless, it is crucial to emphasize the meticulous selection of the precise steel type and composition to satisfy the distinctive needs of the aerospace industry, encompassing weight reduction and corrosion resistance.

- Q: What are the different types of surface patterns available for steel sheets?

- There are several different types of surface patterns available for steel sheets, including smooth, textured, embossed, diamond, and perforated patterns.

- Q: Can steel sheets be used for food processing or storage?

- Using steel sheets for food processing or storage is not recommended. Although steel is a durable material commonly used in various industries, including food processing, it is not suitable for direct contact with food. Steel sheets may contain chemicals like zinc coating or other metallic coatings, which can contaminate the food and pose health risks. Moreover, steel sheets are prone to rusting, and rust can also contaminate the food. To ensure the safety and quality of the food, it is recommended to utilize food-grade materials like stainless steel or food-grade plastic for food processing and storage.

- Q: Can steel sheets be used in the manufacturing of appliances?

- Yes, steel sheets can be used in the manufacturing of appliances. Steel is a widely used material in the manufacturing industry due to its strength, durability, and versatility. Steel sheets can be shaped, formed, and cut into various sizes and designs to suit the specific requirements of different appliances. Additionally, steel is resistant to corrosion, making it suitable for appliances that may come into contact with water or other liquids. It is also a good conductor of heat, which is advantageous for appliances that require efficient heat transfer. Therefore, steel sheets are commonly used in the production of appliances such as refrigerators, ovens, dishwashers, washing machines, and many others.

- Q: Are steel sheets available in different hardness levels?

- Yes, steel sheets are available in different hardness levels.

- Q: Is galvanized steel plate fire-resistant?

- Galvanized steel is mainly antiseptic, and he has no fire protection

Send your message to us

Color glazed steel sheet with cheap steel prices

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 35234 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords