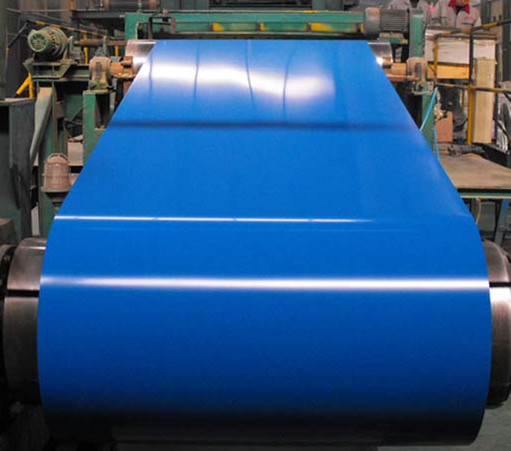

Prepainted Galvanized Color Steel Plate High Quality Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

High Quality Low Price Prepainted Galvanized Color Steel Plate Details

| Name | Low price high quality prepainted galvanized color steel plate | Standard | AISI,ASTM,BS,DIN,JIS |

| Grade | EN10142, EN10346, EN10169, JIS G3302, JIS G3321 etc, as required | Thickness | 0.14-1.2mm |

| Place of Origin | China (Mainland) | Model Number | PPGI, PPGL, TSGCC, CGCC, CGLCC, etc |

| Technique | Cold Rolled | Surface Treatment | Coated |

| Application | Structural use ,roofing, commercial use, household appliance,etc. | Special Use | High-strength Steel Plate |

| Width | 600--1250mm(as customized) | Length | as customers requirement |

| Color | RAL color or as you wanted |

Packaging Detail:Seaworthy packing. Or as customer's request.

Delivery Detail:PPGI/PPGL :15--30days after receiving your deposit or L/C

High Quality Low Price Prepainted Galvanized Color Steel Plate Feature

1) Excellent Corrosion Resistance, Heat Resistance.

2) Formability.

3) Decoration.

4) Excellent Workability.

5) Various color

High Quality Low Price Prepainted Galvanized Color Steel Plate Pictures

- Q: What is the typical composition of stainless steel sheets?

- The primary constituents of stainless steel sheets are iron, chromium, and nickel, which are responsible for its distinct properties. The proportions of these three elements can vary depending on the specific grade of stainless steel being utilized. On average, stainless steel sheets typically contain approximately 10-30% chromium and 8-20% nickel. Moreover, small quantities of other elements like carbon, manganese, and molybdenum may be present to further augment the strength, corrosion resistance, and other desired characteristics of the stainless steel. The composition of stainless steel sheets is meticulously balanced to attain the desired amalgamation of durability, strength, and resistance to corrosion, which makes it a highly favored choice across industries such as construction, automotive, and manufacturing.

- Q: What is the maximum temperature resistance of steel sheets?

- The maximum temperature resistance of steel sheets varies depending on the specific type of steel and its composition. However, in general, stainless steel has good heat resistance and can withstand temperatures up to about 1200 degrees Celsius (2200 degrees Fahrenheit) without losing its strength or structural integrity. High carbon steels, on the other hand, can handle temperatures up to about 900 degrees Celsius (1650 degrees Fahrenheit) before they start to lose their mechanical properties. It is important to note that these temperature limits are approximate and may vary depending on factors such as the duration of exposure, the presence of other elements or impurities in the steel, and the specific application in which the steel sheets are being used. Therefore, it is always advisable to consult the manufacturer's specifications or conduct further research to determine the exact maximum temperature resistance of a particular type of steel sheet.

- Q: What are the different packaging options for steel sheets?

- Some common packaging options for steel sheets include bundles, coils, crates, and pallets. Bundles are typically used for smaller quantities and consist of multiple sheets bound together with metal or plastic straps. Coils are used for long sheets and are tightly wound into cylindrical shapes. Crates are wooden or metal structures that provide protection during transportation and storage. Pallets are flat structures on which steel sheets are stacked and secured using straps or stretch wrap. These packaging options ensure safe handling and transportation of steel sheets while preventing damage or deformation.

- Q: Can steel sheets be used for storage racks?

- Yes, steel sheets can be used for storage racks. Steel sheets are known for their durability and strength, making them an ideal material for storage racks. They can support heavy loads and provide stability to the storage system. Steel sheets can be easily fabricated and customized to fit the specific requirements of the storage space. Additionally, steel is resistant to corrosion, ensuring the longevity of the storage racks and making them suitable for both indoor and outdoor use.

- Q: Can steel sheets be used for manufacturing automotive parts?

- Yes, steel sheets can be used for manufacturing automotive parts. Steel sheets are widely used in the automotive industry due to their strength, durability, and cost-effectiveness. They can be easily formed, welded, and shaped into various automotive components such as body panels, chassis parts, and structural elements.

- Q: What material is steel plate against drilling?

- All high nickel, high tungsten, or both titanium (tungsten carbide and titanium carbide), cobalt, molybdenum, niobium and other elements of the steel can be drilled.

- Q: Can steel sheets be used for electrical conductivity?

- No, steel sheets are not typically used for electrical conductivity as they are generally poor conductors of electricity.

- Q: Are steel sheets suitable for cold storage applications?

- Yes, steel sheets are suitable for cold storage applications. Steel is known for its durability, strength, and resistance to extreme temperatures, making it an ideal material for cold storage facilities. It helps maintain a consistent temperature, prevents condensation, and provides excellent insulation, ensuring the quality and freshness of stored goods. Additionally, steel sheets are easy to clean, maintain, and can withstand heavy loads, making them a reliable choice for cold storage applications.

- Q: How are steel sheets produced?

- Steel sheets are produced through a process called steel rolling, where large steel slabs are heated and passed through a series of rollers to reduce their thickness and achieve the desired shape and size.

- Q: Can steel sheets be used for manufacturing solar panels?

- No, steel sheets cannot be used for manufacturing solar panels. Solar panels are typically made using materials such as silicon, glass, and various semiconductors, which are specifically designed to efficiently capture and convert sunlight into electricity. Steel sheets do not possess the necessary properties and characteristics required for the functioning of solar panels.

Send your message to us

Prepainted Galvanized Color Steel Plate High Quality Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords