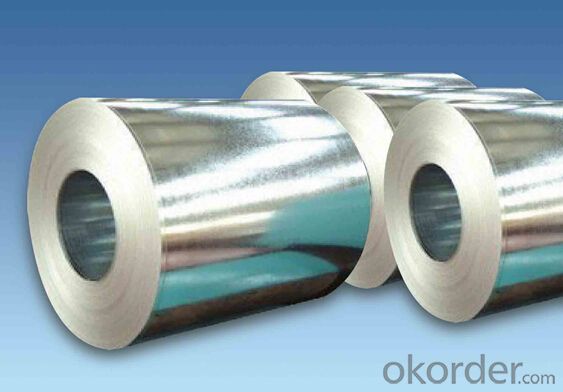

Grade JIS SGCH G550 Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade JIS SGCH G550 Galvanized Steel Coil

Specification of Grade Grade JIS SGCH G550 Galvanized Steel Coil

1. Galvanized Steel Coil

(1) Width: 600-1570mm

(2) Thickness: 0.13-5.0mm

(3) Grade: JIS G3302-SGCC-SGC570, SGCH (full hard-G550), SGHC-SGH540

EN10346-DX51D+Z, DX53D+Z, S250GD-S550GD

STM A653-CS-B, SS255-SS550

(4) Zinc Coating: Z40g/m2~Z500g/m2 (both side total coating thickness)

2. Galvalume Steel Coil

(1) Width: 600~1500mm

(2) Thickness: 0.15~2.30mm

(3) Grade: JIS G3321-SGLCC, SGLC400-570, (G550)

EN10346-DX51D+AZ, DX53D+AZ, S250-S550

ASTM A792M CS-B, SS255-SS550

(4) AZ Coating: AZ50~AZ185g/m2

3. Prepainted Galvanized Steel Coil (PPGI)

(1) Width: 600~1250mm

(2) Thickness: 0.19~1.50mm

(3) Grade: JIS G3312-CGCC, CGC340-570, (G550)

ASTM A755M CS-B, SS255-SS550

(4) Zinc Coating: Z40g/m2~Z500g/m2 (both side total coating thickness)

4. Prepainted Galvanized Steel Coil (PPGL)

(1) Width: 600~1250mm

(2) Thickness: 0.20~1.50mm

(3) Grade: JIS G3322-CGLCC, CGLC340-570, (G550)

ASTM A755M CS-B, SS255-SS550

(4) AZ Coating: AZ50~AZ185g/m2 (both side total coating thickness)

5. Cold Rolled Steel Coil (Soft) (for further information, pls click the product name)

(1) Width: 600~1570mm

(2) Thickness: 0.13~2.50mm

(3) Grade: JIS G3141-SPCC-SD, SPCD-SD, SPEC-SD

JIS G3135-SPFC 340/390/440

EN10130-DC01, DC03, DC04

SAE1006, SAE1008

ASTM A424-TypeⅡ

6. Cold Rolled Steel Coil (Full Hard) (for further information, pls click the product name)

(1) Width: 600~1570mm

(2) Thickness: 0.13~2.50mm

(3) Grade: JIS G3141-SPCC-1B, SPCC-1D

7. Hot Rolled Steel Coil

(1) Width: 1000~1524mm

(2) Thickness: 1.20~16.5mm, other thickness can be negotiation

(3) Grade: JIS G3101-SS400, JIS G3132-SPHT1/2/3, ASTM A36, Q195, Q235 etc.

Company Introduction of the Grade JIS SGCH G550 Galvanized Steel Coil

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery Grade Grade JIS SGCH G550 Galvanized Steel Coil

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show:

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the different methods of improving the creep resistance of special steel?

- There are several methods for improving the creep resistance of special steel. One approach is through alloying, where specific elements such as chromium, molybdenum, and tungsten are added to enhance the steel's creep resistance. Another method involves heat treatment processes such as annealing or quenching and tempering, which can refine the microstructure and increase the steel's resistance to creep deformation. Surface treatments like carburizing or nitriding can also be employed to improve the creep resistance of special steel. Furthermore, controlling the grain size and texture through techniques like grain refinement or grain boundary engineering can enhance the steel's resistance to creep. Finally, proper design considerations, such as reducing stress concentrations and optimizing component geometry, can also contribute to improving the creep resistance of special steel.

- Q: Can special steel be used for manufacturing tools?

- Certainly, tools can be manufactured using special steel. Special steel refers to a specific type of steel that is meticulously engineered and designed to possess unique properties and characteristics. These properties make it well-suited for specific applications, such as manufacturing tools. In fact, special steel is often preferred for tool production due to its exceptional strength, hardness, and durability. These qualities allow tools made from special steel to withstand high levels of stress, wear, and impact. Consequently, they are ideal for demanding tasks like cutting, drilling, shaping, and machining. Additionally, special steel also exhibits excellent heat resistance, corrosion resistance, and dimensional stability. These additional attributes further enhance its suitability for tool manufacturing. Overall, the use of special steel in tool production guarantees the creation of top-quality, long-lasting, and efficient tools capable of effectively performing various tasks across different industries.

- Q: How does special steel contribute to the longevity of products?

- Special steel contributes to the longevity of products by providing enhanced strength, durability, and resistance to wear and corrosion. Its unique composition and manufacturing processes make it ideal for applications where strength and longevity are crucial, such as in the automotive, aerospace, and construction industries. By using special steel, products can withstand extreme conditions and heavy use over extended periods, ensuring a longer lifespan and reducing the need for frequent replacements.

- Q: How is special steel used in the telecommunications supply chain?

- Special steel is used in the telecommunications supply chain for various applications. It is commonly used in the manufacturing of infrastructure components such as transmission towers, antenna supports, and cable trays. The high strength and durability of special steel make it suitable for withstanding extreme weather conditions and ensuring the stability and reliability of telecommunications networks. Additionally, special steel is also used in the production of cables, connectors, and other equipment that require corrosion resistance and electrical conductivity, contributing to the efficient transmission of signals in the telecommunications industry.

- Q: What are the specific requirements for special steel used in the chemical industry?

- The specific requirements for special steel used in the chemical industry include corrosion resistance, high strength, and the ability to withstand extreme temperatures and pressures. Additionally, it should have excellent weldability and formability, as well as resistance to various chemicals and acids commonly found in chemical processes.

- Q: What is the role of special steel in the construction industry?

- Special steel plays a crucial role in the construction industry as it provides strength, durability, and resistance to various environmental factors. It is commonly used in the construction of high-rise buildings, bridges, and infrastructure projects. Special steel's unique properties, such as high tensile strength, corrosion resistance, and heat resistance, make it suitable for critical applications where standard steel may not suffice. It ensures the structural integrity and safety of construction projects, making it an essential material in the industry.

- Q: What are the emerging trends in special steel production?

- The special steel production industry is being shaped by several emerging trends: 1) The industry is experiencing an increasing demand for high-performance alloys. Technological advancements and industrial applications require special steels with superior properties, such as high strength, corrosion resistance, and heat resistance. This has led to a higher demand for alloys like stainless steel, tool steel, and superalloys. 2) Advanced manufacturing techniques, such as additive manufacturing (3D printing) and precision machining, are being adopted for special steel production. These techniques allow for the production of complex geometries and customized components, resulting in improved efficiency and reduced material waste. 3) Sustainability is a key focus in the steel industry. Special steel producers are adopting sustainable practices, such as using recycled materials, energy-efficient production processes, and waste management strategies. Investments in cleaner technologies are being made to meet the growing demand for sustainable steel products. 4) The integration of digital technologies, automation, and data analytics, known as Industry 4.0, is revolutionizing special steel production. Real-time monitoring, predictive maintenance, and optimization of production parameters are made possible through Industry 4.0 solutions. This leads to increased productivity, quality, and cost-effectiveness. 5) Special steel producers are developing new alloys to meet the specific requirements of emerging industries like aerospace, renewable energy, and electric vehicles. For example, lightweight, high-strength steels are being developed for aerospace applications, and corrosion-resistant steels for offshore wind turbines. 6) Collaborations and partnerships between special steel producers, research institutions, universities, and other industry players are on the rise. These collaborations drive innovation, knowledge sharing, and the development of new steel grades, applications, and production processes. In conclusion, the future of special steel production is being shaped by the demand for high-performance alloys, adoption of advanced manufacturing techniques, focus on sustainability, integration of Industry 4.0 technologies, development of alloys for emerging industries, and collaborations. These trends create opportunities for growth and innovation in the industry.

- Q: What is the role of heat treatment in special steel?

- The role of heat treatment in special steel is to enhance its mechanical properties and improve its performance by altering its microstructure through controlled heating and cooling processes. This helps to achieve desired properties such as increased hardness, strength, toughness, and ductility, as well as improved wear resistance and corrosion resistance. Heat treatment also allows for the refinement of grain structure, elimination of internal stresses, and modification of the steel's crystalline structure, which ultimately improves the overall quality and usability of special steel in various applications.

- Q: What are the requirements for special steel used in power generation equipment manufacturing?

- The requirements for special steel used in power generation equipment manufacturing include high strength, excellent corrosion resistance, good thermal conductivity, and the ability to withstand high temperatures and pressures. Additionally, the steel should have low levels of impurities and be able to maintain its mechanical properties over an extended period of time.

- Q: How does the heat treatment process affect special steel?

- The heat treatment process can significantly impact the properties of special steel. It involves heating the steel to a specific temperature and then cooling it in different ways to achieve desired hardness, strength, and other mechanical properties. By carefully controlling the heating and cooling rates, the heat treatment process can alter the microstructure of the steel, allowing for the formation of various phases and structures. This can result in improved hardness, toughness, and wear resistance, making the special steel more suitable for specific applications. Additionally, heat treatment can also relieve internal stresses and improve dimensional stability, enhancing the overall performance and durability of the special steel.

Send your message to us

Grade JIS SGCH G550 Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords