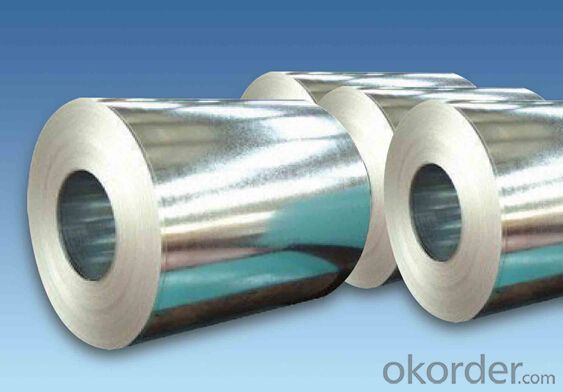

Grade JIS G3302-SGCC-SGC570 Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade JIS G3302-SGCC-SGC570 Galvanized Steel Coil

Specification of Grade JIS G3302-SGCC-SGC570 Galvanized Steel Coil

1. Galvanized Steel Coil

(1) Width: 600-1570mm

(2) Thickness: 0.13-5.0mm

(3) Grade: JIS G3302-SGCC-SGC570, SGCH (full hard-G550), SGHC-SGH540

EN10346-DX51D+Z, DX53D+Z, S250GD-S550GD

ASTM A653-CS-B, SS255-SS550

(4) Zinc Coating: Z40g/m2~Z500g/m2 (both side total coating thickness)

2. Galvalume Steel Coil

(1) Width: 600~1500mm

(2) Thickness: 0.15~2.30mm

(3) Grade: JIS G3321-SGLCC, SGLC400-570, (G550)

EN10346-DX51D+AZ, DX53D+AZ, S250-S550

ASTM A792M CS-B, SS255-SS550

(4) AZ Coating: AZ50~AZ185g/m2

3. Prepainted Galvanized Steel Coil (PPGI)

(1) Width: 600~1250mm

(2) Thickness: 0.19~1.50mm

(3) Grade: JIS G3312-CGCC, CGC340-570, (G550)

ASTM A755M CS-B, SS255-SS550

(4) Zinc Coating: Z40g/m2~Z500g/m2 (both side total coating thickness)

4. Prepainted Galvanized Steel Coil (PPGL)

(1) Width: 600~1250mm

(2) Thickness: 0.20~1.50mm

(3) Grade: JIS G3322-CGLCC, CGLC340-570, (G550)

ASTM A755M CS-B, SS255-SS550

(4) AZ Coating: AZ50~AZ185g/m2 (both side total coating thickness)

5. Cold Rolled Steel Coil (Soft) (for further information, pls click the product name)

(1) Width: 600~1570mm

(2) Thickness: 0.13~2.50mm

(3) Grade: JIS G3141-SPCC-SD, SPCD-SD, SPEC-SD

JIS G3135-SPFC 340/390/440

EN10130-DC01, DC03, DC04

SAE1006, SAE1008

ASTM A424-TypeⅡ

6. Cold Rolled Steel Coil (Full Hard) (for further information, pls click the product name)

(1) Width: 600~1570mm

(2) Thickness: 0.13~2.50mm

(3) Grade: JIS G3141-SPCC-1B, SPCC-1D

7. Hot Rolled Steel Coil

(1) Width: 1000~1524mm

(2) Thickness: 1.20~16.5mm, other thickness can be negotiation

(3) Grade: JIS G3101-SS400, JIS G3132-SPHT1/2/3, ASTM A36, Q195, Q235 etc.

Company Introduction of the Grade JIS G3302-SGCC-SGC570 Galvanized Steel Coil

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery Grade JIS G3302-SGCC-SGC570 Galvanized Steel Coil

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show:

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: Can special steel be used for musical instruments?

- Yes, special steel can be used for musical instruments. In fact, many high-quality instruments such as saxophones, trumpets, and guitars are made using different types of steel. Special steel alloys like stainless steel or nickel silver offer unique tonal qualities and durability, making them suitable for producing musical instruments with excellent sound projection and longevity.

- Q: Can special steel be used in the oil refinery industry?

- Yes, special steel can be used in the oil refinery industry. Special steel, such as stainless steel or high alloy steel, is often preferred in the oil refinery industry due to its superior corrosion resistance and high temperature strength. It is commonly used in various applications, including piping, tanks, heat exchangers, and valves, to ensure durability and reliability in the harsh and corrosive environment of oil refineries.

- Q: How does surface treatment affect the performance of special steel?

- Surface treatment plays a crucial role in enhancing the performance of special steel. The primary purpose of surface treatment is to alter the surface properties of the steel to meet specific requirements and improve its performance in various applications. One significant effect of surface treatment on special steel is increased corrosion resistance. By applying coatings or treatments such as galvanization, electroplating, or passivation, the steel's surface becomes more resistant to the damaging effects of moisture, chemicals, and other corrosive agents. This is particularly important in industries like construction, automotive, or marine, where steel is exposed to harsh environments. Surface treatment also affects the wear resistance of special steel. Through processes like carburizing, nitriding, or boriding, a thin layer of hard and wear-resistant material is formed on the steel's surface. This significantly improves its ability to withstand friction, abrasion, and mechanical stress, making it suitable for applications involving heavy machinery, cutting tools, or bearings. Furthermore, surface treatment can enhance the aesthetic appeal of special steel. Techniques like polishing, grinding, or coating can improve the steel's appearance, making it more visually appealing for architectural or decorative purposes. Another important aspect affected by surface treatment is the steel's adhesion properties. By modifying the surface through processes such as shot peening or surface etching, the steel becomes more receptive to adhesives, paints, or coatings. This improves the bond strength between the steel and other materials, making it suitable for applications where adhesion is critical, such as in aerospace or electronics industries. In summary, surface treatment significantly impacts the performance of special steel. It enhances corrosion resistance, wear resistance, adhesion properties, and aesthetic appeal. By selecting the appropriate surface treatment techniques, manufacturers can tailor the steel's surface properties to meet specific application requirements, thereby maximizing its performance and extending its lifespan.

- Q: What are the main characteristics of pressure vessel steel?

- The main characteristics of pressure vessel steel include high strength, good weldability, excellent toughness, and resistance to corrosion and high temperatures. These properties make it suitable for containing fluids or gases under high pressure, ensuring the safety and reliability of the vessel in various industrial applications.

- Q: What are the different manufacturing processes used for special steel?

- There are several different manufacturing processes used for special steel, depending on the specific requirements and properties desired for the final product. Some of the commonly used manufacturing processes for special steel include: 1. Electric Arc Furnace (EAF): This process involves melting scrap metal in an electric arc furnace, where high electrical current passes through the electrodes to melt the metal. EAF is commonly used for producing stainless steel, tool steel, and alloy steel. 2. Basic Oxygen Furnace (BOF): BOF is a process where molten iron from a blast furnace is combined with scrap metal and oxygen is blown through the mixture to remove impurities. BOF is widely used for producing carbon and low-alloy steels. 3. Vacuum Degassing: This process is used to remove impurities like hydrogen, nitrogen, and sulfur from steel by subjecting it to a vacuum environment. Vacuum degassing is often employed for producing high-quality and ultra-clean special steels. 4. Continuous Casting: In this process, molten steel is poured into a water-cooled mold, where it solidifies into a continuous strand. Continuous casting helps to produce steel with a consistent shape, size, and internal structure, and is commonly used for semi-finished products like billets, slabs, and blooms. 5. Powder Metallurgy: This manufacturing process involves compacting metal powders into the desired shape and then sintering them at high temperatures to bond the particles together. Powder metallurgy is often used for producing special steels with specific properties, such as high strength, wear resistance, or corrosion resistance. 6. Heat Treatment: Heat treatment processes like annealing, quenching, and tempering are commonly employed to modify the microstructure and properties of special steels. These processes involve heating the steel to specific temperatures and then cooling it in a controlled manner to achieve desired hardness, toughness, and other mechanical properties. Each of these manufacturing processes has its own advantages and limitations, and the choice of process depends on factors such as the type of steel required, the desired properties, and the cost-effectiveness of the process for a particular application.

- Q: What are the main advantages of using special steel in the power generation industry?

- The main advantages of using special steel in the power generation industry are its exceptional strength, resistance to corrosion and high-temperature capabilities. These properties make special steel highly suitable for critical components like turbines, boilers, and generators, ensuring their durability and reliability in harsh operating conditions. Additionally, special steel's ability to withstand extreme pressure and stress enhances the overall safety and efficiency of power plants.

- Q: What are the different methods of analyzing the microstructure of special steel?

- The microstructure of special steel can be analyzed using various methods. These methods involve examining and characterizing the steel at a microscopic level to gain insights into its composition, grain structure, and other features. Some commonly used methods include: 1. Optical Microscopy: By using light microscopy, the microstructure of special steel can be observed. This method allows for the identification of different phases, grain boundaries, inclusions, and other features. It provides valuable information about the size, distribution, and morphology of constituents in the steel. 2. Scanning Electron Microscopy (SEM): SEM is a powerful technique that utilizes a high-energy electron beam to analyze the microstructure of special steel. It offers detailed information about the steel's surface topography, morphology, and elemental composition. SEM is particularly useful for studying precipitates, segregation, and other microstructural defects. 3. Transmission Electron Microscopy (TEM): TEM is an advanced technique that enables analysis of the microstructure at a higher resolution compared to optical and SEM methods. It involves the transmission of electrons through a thin sample, providing information about the crystal structure, dislocations, and other fine details of the microstructure. TEM is especially beneficial for studying nanostructures and interfaces in special steel. 4. X-ray Diffraction (XRD): XRD is a non-destructive method that utilizes X-rays to analyze the crystal structure and identify phases in special steel. It provides information about the crystallographic orientation, grain size, and phase composition of the steel. XRD is widely used for analyzing phase transformations and residual stress in special steel. 5. Electron Backscatter Diffraction (EBSD): EBSD combines SEM with crystallographic analysis to provide information about the crystal orientation, texture, and grain boundaries in special steel. It is useful for studying deformation mechanisms, recrystallization, and grain growth in the steel. 6. Energy Dispersive X-ray Spectroscopy (EDS): EDS is often used in conjunction with SEM or TEM to analyze the elemental composition of special steel. It provides information about the presence and distribution of different chemical elements in the microstructure, aiding in the identification of phases and characterization of inclusions. These methods, among others, offer valuable insights into the microstructure of special steel. They enable researchers and engineers to understand the steel's properties, performance, and potential applications.

- Q: What are the requirements for special steel used in wind turbines?

- The reliability, efficiency, and durability of large-scale renewable energy systems, such as wind turbines, rely heavily on the crucial requirements for special steel. Here are some key considerations: 1. Strength and Durability: To withstand the harsh operating conditions, including strong winds, vibrations, and extreme temperature variations, wind turbine steel must possess exceptional strength and durability. Its high fatigue resistance allows it to endure cyclic loading over the turbine's operational life, which can span up to 20-25 years. 2. Corrosion Resistance: Wind turbines often face corrosive saltwater and salt-laden air in coastal or offshore environments. As a result, the special steel used must exhibit superb corrosion resistance to prevent degradation and ensure long-term performance. 3. Weldability: The steel chosen for wind turbines should be suitable for welding processes, enabling efficient fabrication and assembly of turbine components. Excellent weldability streamlines construction and maintenance, reducing downtime and associated costs. 4. Low Temperature Toughness: Wind turbines are frequently situated in cold regions, such as arctic or mountainous areas. Consequently, the special steel employed must possess good low-temperature toughness, ensuring its mechanical properties remain intact even in frigid climates. 5. Magnetic Properties: Wind turbines utilize electrical components like generators and transformers, which operate within electromagnetic fields. The special steel used in these components should possess specific magnetic properties to minimize energy losses and maximize electrical system efficiency. 6. Cost-effectiveness: While meeting all the aforementioned requirements, the special steel employed in wind turbines must also be cost-effective. Striking a balance between performance and cost ensures the economic viability of wind energy projects. Meeting these requirements is vital for the long-term operation and sustainability of wind turbines, enabling them to generate clean and renewable energy efficiently.

- Q: How long does special steel typically last in various applications?

- The lifespan of special steel can vary in different applications due to various factors. Special steel is renowned for its remarkable strength, durability, and resistance to corrosion, making it suitable for a wide array of applications. However, the actual lifespan of special steel relies on the specific application, maintenance practices, and environmental conditions it encounters. In general, special steel can endure for several decades, or even longer, when utilized in industries like construction, automotive, aerospace, and manufacturing. For example, in building structures, special steel can remain intact for 50 to 100 years due to its robustness and ability to withstand extreme loads and weather conditions. In automotive applications, special steel components such as engine parts, suspension systems, and body frames can have a lifespan of 15 to 30 years, provided they are well-maintained and not subjected to excessive wear and tear. In the aerospace industry, special steel is commonly utilized in crucial components like turbine blades, landing gears, and fuselage structures. These parts undergo rigorous testing and inspection procedures and are designed to last for decades, typically around 30 to 50 years, before necessitating replacement or refurbishment. In manufacturing processes, special steel tools and dies can last anywhere from a few years to several decades, depending on factors such as the intensity of use, the material being processed, and the maintenance practices employed. Proper lubrication, cooling, and regular maintenance can significantly prolong the lifespan of these tools. It is important to note that the lifespan of special steel can be negatively impacted by factors such as exposure to harsh chemicals, high temperatures, aggressive environments, or inadequate maintenance. Consequently, regular inspections, maintenance, and adherence to recommended usage guidelines are crucial in ensuring the longevity of special steel in various applications.

- Q: How does special steel perform in terms of wear resistance in abrasive environments?

- Special steel performs very well in terms of wear resistance in abrasive environments. Its unique composition and treatment processes enhance its hardness and toughness, making it highly resistant to abrasion caused by particles and friction. This allows special steel to withstand harsh conditions and maintain its integrity for prolonged periods, reducing the need for frequent replacements or repairs.

Send your message to us

Grade JIS G3302-SGCC-SGC570 Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords