20Cr Steel Round Bar SAE520 Steel Round Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

20Cr Steel Round Bar SAE520 Steel Round Bar

Product Description:

1.Standard:40Cr,20Cr, 40CrMo4,SCM440,AISI4140, etc.

2.Diameter:25mm-450mm

3.Length:5.8/6m-12m or as required

4.Application:re-manufacture, structural steel etc.

5.Certificates:ISO9001:2008,ISO14001:2004,OHSAS18001

6.Packing: In bundles,Standard export sea-worthy packing or as customer's requirement

7.Shipment: by bulk or by container

8.Quality Contation

Both end of each bar must be cut.

Ladle furnanced and vacuum de-gassed

Show heat No. on each bar

Surface condition the surface of the hot rolled square bar shall befree cracks, scar and wrinkles that affect the use of the

billets. In case there is the above-mentioned defect, it shall be remove.

The mill test certificate shall show the chemical composition, and it is guaranteed that the chemical composition shall be

within the limit stipulated in the contract.

Chemical composition:

Grade | C | Si | Mn | Cr |

20Cr | 0.18-0.24 | 0.17-0.37 | 0.5-0.8 | 0.7-0.9 |

Specification:

OD | Length | Material | Standard | Technique |

16-260mm | 6-12m or aques per request | 20# | GB ASTM DIN | Hot rolled |

16-350mm | 45# | |||

200-500mm | 45# | Forged | ||

20-250mm | 20Cr,40Cr,20-42CrMo | Hot rolled | ||

50-300mm | GCr15 |

Application:

Hot rolled alloy structure steel round bar are widely used in machinery making, autombile making, railway, mine machinery, petoleum machinry, agricultural machinery and civil archtectue such as all kinds of shafts, screws, connecting rods, hardware tools, gears, standard parts, spanners fasteners, structural parts for automobile and agricultural machinery, outer and iner sleeves, rollers and balls for bearing making.

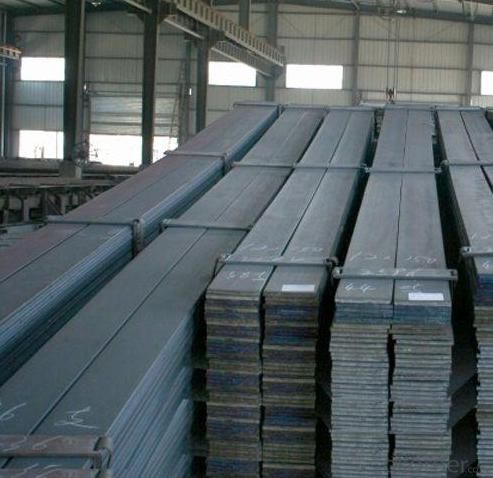

Product Show:

- Q: How are tool steels used in the manufacturing of cutting tools?

- Tool steels are used in the manufacturing of cutting tools due to their excellent hardness, toughness, and wear resistance. These steels are specifically designed to withstand high temperatures, pressures, and repeated impacts during cutting operations. They are used to make various cutting tools like drills, milling cutters, saws, and blades. The high hardness of tool steels allows them to retain their sharpness for longer periods, ensuring efficient cutting performance. Additionally, their toughness helps withstand the mechanical stresses encountered during cutting, while their wear resistance enables them to maintain their cutting edges even after prolonged use. Overall, tool steels are crucial in the manufacturing of cutting tools, enabling precise and efficient material removal processes in various industries.

- Q: How is magnetic stainless steel used in the production of magnetic components?

- Magnetic stainless steel is commonly used in the production of magnetic components due to its unique combination of corrosion resistance and magnetic properties. It is particularly suitable for applications where both strength and resistance to oxidation are required. The stainless steel is typically formed into various shapes and sizes, such as rods or sheets, and then processed into the desired magnetic component. This can include items like magnets, transformer cores, or magnetic shielding components. The magnetic properties of the stainless steel facilitate efficient magnetization, making it a valuable material for the production of magnetic components in various industries.

- Q: Can special steel be used in the defense equipment manufacturing industry?

- Yes, special steel can be used in the defense equipment manufacturing industry. Special steel, with its enhanced properties such as high strength, durability, and resistance to wear and corrosion, is often required for the manufacturing of critical components in defense equipment. It is commonly used in the production of military vehicles, aircraft, missiles, and various weapon systems. The unique characteristics of special steel make it suitable for withstanding extreme conditions and providing optimal performance in defense applications.

- Q: What are the different methods of preventing intergranular corrosion in special steel?

- There are several methods available to prevent intergranular corrosion in special steel. 1. Heat Treatment: One effective method is to subject the steel to a heat treatment process called solution annealing. This involves heating the steel to a high temperature and then rapidly cooling it. This process helps to dissolve any precipitates or carbides that may have formed along the grain boundaries, thus reducing the risk of intergranular corrosion. 2. Alloying: Another approach is to add specific alloying elements to the steel composition. For example, the addition of elements like chromium and molybdenum can enhance the steel's resistance to intergranular corrosion. These alloying elements form a protective oxide layer on the surface, preventing corrosion from occurring along the grain boundaries. 3. Passivation: Passivation involves treating the steel surface with chemicals that create a protective layer. This layer acts as a barrier, preventing the corrosive environment from reaching the grain boundaries. Commonly used passivation techniques include acid pickling and electrochemical methods. 4. Sensitization Control: Special attention must be given to the sensitization process, which occurs when the steel is exposed to high temperatures for a prolonged period. This can lead to the precipitation of chromium carbides along the grain boundaries, making the steel susceptible to intergranular corrosion. By carefully controlling the heating and cooling rates during processing, sensitization can be minimized or prevented. 5. Corrosion Inhibitors: Another option is to use corrosion inhibitors, which are chemicals that can be applied to the steel surface to protect it from corrosion. These inhibitors form a protective film on the surface, preventing the corrosive agents from attacking the grain boundaries. It is important to note that the specific method used will depend on the type of special steel and the intended application. The selection of the most appropriate method should be based on a thorough understanding of the steel's composition, processing conditions, and the anticipated corrosive environment.

- Q: What are the properties of high-strength tool steel?

- High-strength tool steel typically possesses excellent hardness, toughness, wear resistance, and ability to retain its shape even under high temperatures and pressures. It is known for its durability, ability to withstand heavy loads, and resistance to deformation, making it ideal for demanding applications in tooling and machining.

- Q: How does special steel contribute to the aerospace material recyclability?

- Special steel contributes to the aerospace material recyclability by offering high durability and strength, making it a preferred material for various aircraft components. Its recyclability is enhanced through processes such as melting and reformation, allowing the steel to be reused in new applications. This reduces the need for new steel production, conserves resources, and minimizes waste generation in the aerospace industry.

- Q: How does special steel contribute to the energy sector?

- Special steel contributes to the energy sector by providing high-strength materials that are essential for the construction of various energy infrastructure projects. It is used in the manufacturing of turbines, generators, and power transmission equipment, ensuring efficient energy production and distribution. Additionally, special steel is crucial in the construction of pipelines and storage tanks for the oil and gas industry, enhancing their durability and safety. Overall, the use of special steel in the energy sector plays a vital role in supporting reliable and sustainable energy production.

- Q: How does special steel contribute to the manufacturing of surgical instruments?

- Special steel, which is also known as stainless steel, plays a vital role in the production of surgical instruments. Its exceptional properties make it an ideal material for manufacturing high-quality surgical instruments used in various medical procedures. To begin with, special steel exhibits a high resistance to corrosion and rust. Surgical instruments are constantly exposed to bodily fluids, sterilization processes, and harsh cleaning agents. The corrosion resistance of special steel guarantees the durability of these instruments, enabling them to withstand repeated use and cleaning without compromising their integrity. Furthermore, special steel possesses excellent strength and hardness characteristics. Surgical instruments must be robust and capable of withstanding the forces and pressures exerted during surgeries. The high strength and hardness of special steel ensure that these instruments retain their shape and sharpness even after multiple uses, minimizing the risk of breakage or deformation during critical procedures. Moreover, special steel is biocompatible, meaning it does not elicit reactions or complications when in contact with bodily tissues or fluids. This is particularly important for surgical instruments that come into direct contact with patients' bodies. The biocompatibility of special steel guarantees that there are no adverse reactions or complications when these instruments are used in surgeries, thereby reducing the risk of infections or other complications. In addition, special steel is highly machinable and can be easily molded into intricate shapes and designs. Surgical instruments require precision and accuracy to effectively fulfill their intended functions. The machinability of special steel allows manufacturers to create complex instruments with fine details and features, ensuring their optimal performance during surgical procedures. Furthermore, special steel can be efficiently sterilized. Sterilization is a critical step in ensuring the safety and effectiveness of surgical instruments. Special steel's ability to withstand high temperatures and various sterilization methods, such as autoclaving or ethylene oxide gas sterilization, makes it an ideal choice of material for surgical instruments. In conclusion, special steel significantly contributes to the manufacturing of surgical instruments due to its corrosion resistance, strength, biocompatibility, machinability, and sterilization capabilities. These properties guarantee that surgical instruments made from special steel are durable, reliable, safe, and effective in medical procedures, ultimately enhancing the success of surgeries and improving patient outcomes.

- Q: How does special steel contribute to the chemical resistance of products?

- Special steel contributes to the chemical resistance of products by offering enhanced corrosion resistance properties due to its unique composition and manufacturing process. It contains alloying elements such as chromium and nickel, which form a protective oxide layer on the surface that prevents the steel from reacting with corrosive substances. This makes special steel highly resistant to acids, alkalis, and other chemicals, ensuring the longevity and reliability of products in various industries.

- Q: How does special steel contribute to the automotive suspension industry?

- Special steel contributes to the automotive suspension industry by providing high strength and durability to suspension components. It allows for lighter and more efficient designs, improving handling, stability, and overall performance of vehicles. Special steel also enhances safety by increasing the ability to absorb and dampen shocks and vibrations, resulting in a smoother and more comfortable ride for passengers.

Send your message to us

20Cr Steel Round Bar SAE520 Steel Round Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords