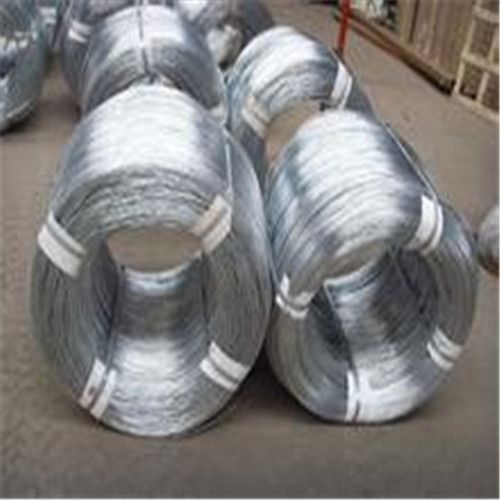

Good Quality Hot Dipped Galvanised Steel Wire In Big Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Commercial Galvanised Steel Wire

(1) Quality : Meet GB/T 343 standard and other requirements of relevant standards .

(2) Zinc Coating: Meet GB/T 15393 standard and other requirements of relevant standards .

(3) Raw Material : Wire rod ——1006 , 1008 , 1018 , Q195 , etc, and zinc with 99.995% purity.

(4) Tensile Strength Range

Size (mm) | Tensile Strength (mpa) |

0.15-1.60 | 290-550 |

0.65-1.60 | 400-550 |

1.61-6.00 | 400-1200 |

(5) Application : Used in wire mesh , artware , metal hose , binding for agriculture and construction , etc.

(6) Packing

Size (mm) | Coil Size | Spool Packing | Big Coil Packing | |

ID (mm) | OD (mm) | |||

0.15-0.26 | 6 inch | 1-14kg/spool | ||

0.27-0.60 | 8 inch | 1-100kg/spool | ||

0.61-1.60 | 12/14/16 inch | 1-100kg/spool | 250-400 | 400-770 |

1.61-6.00 | 14-500kg/spool | 450 | 800 | |

508 | 840 | |||

(7) Zinc Coating

Meet GB/T 15393 standard.

Size (mm) | Weight of Zinc-Coating ( g/m2 ) | |||||||

A | AB | B | C | D | E | F | ||

A1 | B2 | |||||||

≤0.25 | 30 | 20 | 18 | |||||

>0.25-0.40 | 30 | 25 | 20 | |||||

>0.40-0.50 | 30 | 20 | ||||||

>0.50-0.60 | 35 | 20 | ||||||

>0.60-0.80 | 120 | 110 | 40 | 20 | ||||

>0.80-1.00 | 150 | 130 | 45 | 25 | ||||

>1.00-1.20 | 180 | 150 | 50 | 25 | ||||

>1.20-1.40 | 200 | 160 | 50 | 25 | ||||

>1.40-1.60 | 220 | 180 | 50 | 35 | 30 | |||

>1.60-1.80 | 220 | 180 | 70 | 40 | 30 | |||

>1.80-2.20 | 230 | 200 | 80 | 50 | 40 | |||

>2.20-2.50 | 240 | 210 | 80 | 55 | 40 | |||

>2.50-3.00 | 250 | 230 | 90 | 70 | 45 | |||

>3.00-4.00 | 270 | 250 | 100 | 85 | 60 | 30 | ||

>4.00-5.20 | 290 | 270 | 110 | 95 | 70 | 40 | ||

>5.20-6.00 | 290 | 270 | 245 | 110 | 100 | 80 | 50 | |

- Q: I get how to solder one wire to the inverter, but how do I do multiple wires? Do I connect end-on-end, or all at the same source? I couldn't find a good website for doing multiple wires...

- don't okorder /

- Q: while changing a lighting fixture i accidently pulled out the white wire while trying to strip it of the three caps in the electrical box im not sure which one it goes intheres a cap with two black wires and one white running too it another cap with three white wire running two it and a cap with a black wire running too it and the other black wire goes too the fixture which one of these caps do the white wire that connects too the fixture belong in?

- Hi There, The white wire (pigtail) that was pulled loose needs to be connected to the other white wires inside the box. . After that connect the black pigtail (that is hanging loose) and white pigtail to the eterminals on the light fixture. Hope that helps, Al

- Q: I know what spark plugs are and where they are... but not sure what is meant by wires...For example checking/replacing spark plugs and wires to see if a problem is fixed..Are wires what hookup to the spark plugs from the (distributor?)

- The proper name for spark plug wires is: Ignition Wires. You're right, they are the leads that run from the distributor or ignition coil pack to the spark plugs. Some newer cars don't have ignition wires as such. A timed low voltage signal runs from small electrical wires directly to individual ignition coils which snap directly onto the spark plugs. Newer Toyota's are arranged like this.

- Q: I did an engine swap with some friends and everything is in place, from the rebuild 700R4 w/ a shift kit, to the rebuild 350 bored .30 over. But all I have left to do is the wiring, but have no idea how to. So about how much would it cost to have a professional finish the wiring?

- Umm its a carb'ed engine, you only need like 9 wires to it Your stock car's wiring will work for most of it. The starter wiring is 100% the same. The TPIs starter wires will bolt right up too and work on your carb'ed engine Mostly you will be removing/un hooking most wires You have 3 wires to starter, 2 battery cables, 1 12 volt switched wire to the BATT term on hei dizzy, 1 oil pressure wire and 1 water temp wire, and 1 tach wire to the TACH term on hei dizzy

- Q: Which television show is better, Oz or the Wire? Why?

- The Wire by far. Who wants to watch a bunch of inmates sodomizing each other?

- Q: Can anyone give me some info or a website with info on which type of wire carries sound waves best?

- Wire does not carry soundwaves, at least not unless the ends of the wire have tin cans on them, and the wire is pulled taut between them! Wires can carry electrical signals which can be used to reproduce the sounds that caused them. This is how sound comes from such as your stereo system's speakers. Maybe that's what you actually mean? If so, copper wires (insulated, of course) are what you want, and if the distance you run the wires is great, the heavier the wire (gauge) the better. If you are transmitting high power to speakers, the wires have to be capable of handling the electrical current involved.

- Q: My computer kept switching all the time when ever I was playing a game. So I had alook in my computer and a wire I bought to extend the CPU wire. The extended wire had burnt so bad that the wire was showing out of the insulting. Will this effect my computer in any way because it was working fine and I shut it down before I took the wire out does it matter that my psu only has a 4 pin for CPU and my motherboard has a 8pin?

- Rule #1, never add extension wires to any PSU to motherboard... If the wire does not fit, get a different case or different PSU... If the PSU is still working, you should be ok. Just get a proper cable to the motherboard (and/or change PSU). Melted wires are an indication of too much current in the wire for a given wire size. In plain words, the wires were too small for the load they carried. Since your mobo has an 8 pin CPU power socket, you MUST get a PSU that has the same 8 pin. In general, 8 pin can carry twice the current that 4 pin can, hence that is why your wires burned, you were putting too much current through the 4 wire, current that needed the 8 wire plug... A 4 wire will not work - ever, it will still overheat.... Get the right power supply !!!

- Q: remote 2 wires for power black - white also 3 wires to goto fan/light ? white - black - red

- wire it black to black white to white. original wiring could be wrong. please better description. for light kit red or blue should connect to that. dont forget grounding wire even though white wire polarizes

- Q: When you buy new earbuds/headphones there are usually two wires connected by a thin piece of rubber.Is it ok to split the two wires that are joined together when you buy them? Im wondering because i need the extra length.

- In almost every case, you just grab the 2 wires close to where they're joined and pull apart gently and it will come apart with no problem at all, and will leave the insulation intact on each wire, as long as you can see the 2 separate wires this should be no problem at all (in fact a lot of earbuds and headphones come with a little rubber piece on the wire that goes up to the split to keep the wires from separating too much, that's how easy they pull apart)

- Q: Okay so bought 2 Kicker Comp C12-8 subs they are single voice coil, and I bought the Kicker DX300.2 amp. I would like to parallel wire thes subs to have a 4 ohm load, But I don't totally get the concept of it. Could somebody explain it, or show me a diagram, or video, or something?

- Parallel is simple. Connect positives to positives and negatives to negatives. Series wiring is the opposite.

Send your message to us

Good Quality Hot Dipped Galvanised Steel Wire In Big Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords