Geotextile Manufacturers in Malaysia/China

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

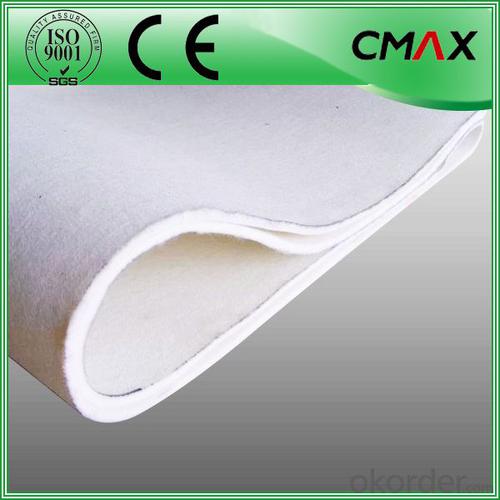

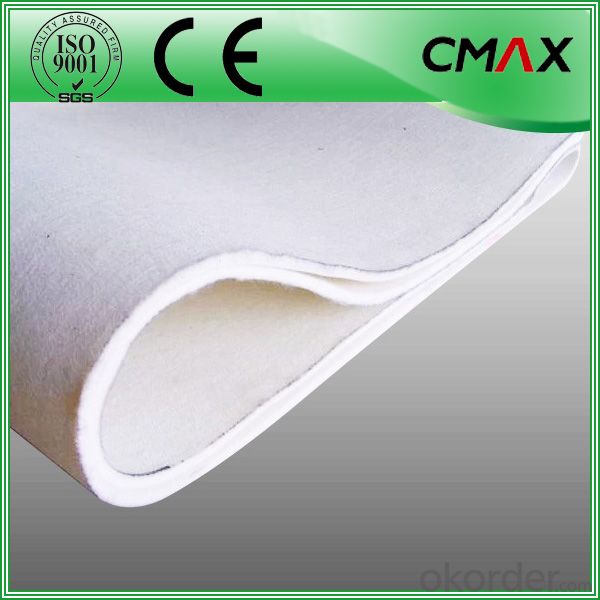

Geotextile Manufacturers in Malaysia/China

Desciriptions:

Geotextile Manufacturers in Malaysia/China are the preferred products for lining projects requiring low permeability , corrosion protection , exceptional chemical and ultraviolet resistance properties , which makes them extremely cost effective for many applications such as waste landfill , storage reservoirs ,canals , powr plants in energy , vapor barriersand waste water treatment in the line of industry and aquaculture and agriculture projects.

Specifications:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

Details of our products:

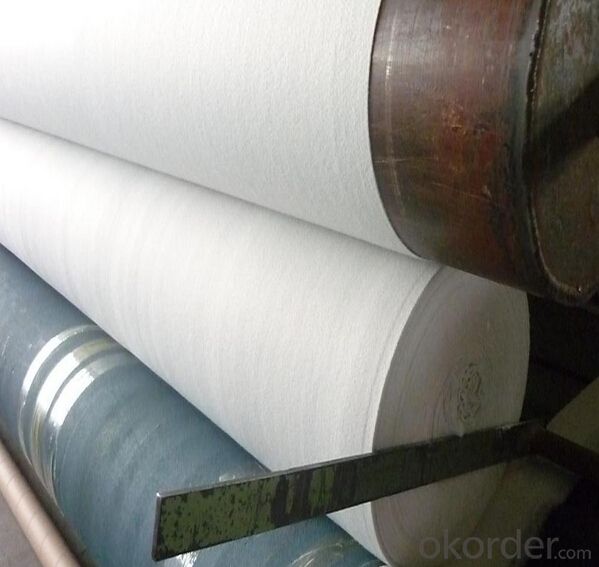

Produce process:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

♦ Packing:in plastic film bag(keep away from moisture) and PP bag or as your customize.

♦ Shipping:By sea or as your customize

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: How do geotextiles help with waste containment systems?

- Geotextiles help with waste containment systems by providing a protective barrier that prevents the escape of waste materials. They effectively control the filtration of liquids and gases, reducing the risk of contamination and environmental damage. Additionally, geotextiles help to reinforce the stability and integrity of waste containment structures, ensuring long-term durability and reducing the potential for leaks or failures.

- Q: How do geotextiles improve the performance of slopes?

- Geotextiles improve the performance of slopes by providing reinforcement and stabilization. They help to prevent erosion, soil movement, and surface runoff by acting as a barrier between the soil layers. Additionally, geotextiles increase the overall strength of the slope, reducing the risk of landslides or slope failures.

- Q: How do geotextiles help with soil reinforcement in retaining walls?

- Geotextiles help with soil reinforcement in retaining walls by acting as a barrier between the soil and the backfill material. They prevent soil erosion and provide stability by distributing the pressure evenly across the wall. Additionally, geotextiles enhance the overall strength and longevity of the retaining wall system.

- Q: What are the benefits of using geotextiles in construction projects?

- Geotextiles offer numerous benefits in construction projects. Firstly, they provide effective soil stabilization by preventing erosion, reducing sedimentation, and enhancing soil strength. Secondly, they act as a barrier against weed growth, enhancing the aesthetics and longevity of the project. Additionally, geotextiles facilitate efficient drainage, preventing water accumulation and potential damage to structures. They also aid in separation and filtration, preventing the mixing of different materials and promoting the flow of water. Furthermore, geotextiles are cost-effective and easy to install, saving both time and labor. Overall, the use of geotextiles in construction projects improves durability, reduces maintenance needs, and ensures long-term sustainability.

- Q: What is the difference between geotextile and impervious geotextile, geotextile and impervious geotextile?

- Geotextile play filter, filter, the role of reinforcement, with water permeability! Anti-seepage geotextile is generally made of geotextile and geomembrane compound, known as composite geomembrane, or simply as impervious geotextile, you can search for geotechnical materials Pan Huijie consultation to understand. Or user name consultation.

- Q: Can geotextiles be used for reinforcement of railway tracks?

- Yes, geotextiles can be used for reinforcement of railway tracks. Geotextiles are commonly used in railway engineering to improve track stability, reduce settlement, and increase load-bearing capacity. They are placed beneath the track ballast to distribute loads more evenly, prevent ballast contamination, and provide separation and filtration functions. Geotextiles can effectively enhance the performance and longevity of railway tracks.

- Q: are they used for same purpose with just different terminology?

- Geotextile; material that can pass water from wicker (woven) or non-woven (non-woven) from the threads or synthetic fibers used in ground work, the synthesis of thin sheets, flexible, permeable used for soil stabilization and improvement Geogrid; Geosynthetic one type of material (geosynthetic) which have openings large enough, typically used to reinforce the soil. And is used to reinforce the retaining wall, usually made ??of Polyester (PET) or Polyethyline High Density (HDPE).

- Q: How do geotextiles help with soil stabilization in construction sites?

- Geotextiles help with soil stabilization in construction sites by providing a barrier that separates and reinforces different layers of soil. They prevent soil erosion, control sediment movement, and enhance the overall stability of the ground. Additionally, geotextiles improve drainage and filtration, allowing excess water to pass through while retaining soil particles, which ultimately strengthens the construction foundation.

- Q: Neighborhoods: anti-seepage composite geotextile testing need to follow which test specifications, and routine testing items.

- There is a special GB ah GBT-1998 I was the production of geotechnical materials

- Q: How are geotextiles used in sports field construction?

- Geotextiles are used in sports field construction to enhance the stability, drainage, and overall performance of the playing surface. They are typically installed as a layer between the subgrade and the topsoil, acting as a barrier to prevent the mixing of different soil layers while still allowing water to permeate through. This helps in preventing the formation of puddles and maintaining a consistent playing surface. Additionally, geotextiles can aid in soil stabilization, reducing the risk of erosion and promoting better turf growth.

Send your message to us

Geotextile Manufacturers in Malaysia/China

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords