Geotextile Filter Fabric Construction Companies

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

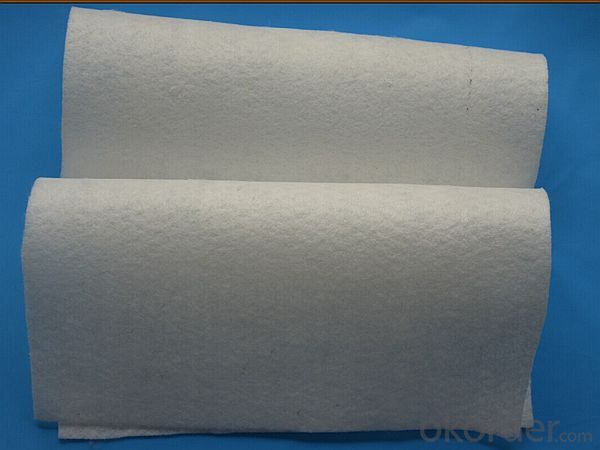

Type:

Geotextiles, Nonwoven Geotextile woven Geotextile

Place of Origin:

Shandong, China (Mainland)

Brand Name:

CMAX

Model Number:

CMAX-S001

Geotextile Type:

Non-Woven Geotextiles Woven Geotextiles

Width:

1m-8m

Length:

Customer Requirment

Weight:

100g/m2-1500g/m2

Geotextile Fabrics - the oldest and most commonly used geosynthetic today - are engineered to provide cost-effective solutions to meet specific design requirements. And although there are at least 80 specific 'applications' for geotextiles that have been developed, a geotextile always performs at least one of five discrete 'functions':

Separation

Reinforcement

Filtration

Drainage

Protection

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

specifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles help in stabilizing railroad tracks?

- Geotextiles help in stabilizing railroad tracks by providing reinforcement and separation between the track components and the underlying soil. They prevent the mixing of soil particles with the track ballast, which can lead to track settlement and degradation. Geotextiles also distribute the load of passing trains more evenly, reducing the risk of track deformation and improving overall stability.

- Q: What is the separation between the roof waterproof protective layer and the waterproof layer?

- That is, at home and home boundaries to break off. Or can not achieve the effect of waterproof

- Q: Are geotextiles suitable for use in geogrid reinforced slopes?

- Yes, geotextiles are suitable for use in geogrid reinforced slopes. Geotextiles can provide separation, filtration, and erosion control functions, which are essential for maintaining the stability and performance of geogrid reinforced slopes.

- Q: How do geotextiles contribute to the stability of railroad ballast?

- Geotextiles contribute to the stability of railroad ballast by providing separation, filtration, and reinforcement functions. They act as a barrier between the ballast and underlying soil, preventing the mixing of materials and maintaining the integrity of the track system. Geotextiles also help to filter out fine particles, preventing clogging and maintaining proper drainage. Additionally, they provide reinforcement, distributing the load more evenly and reducing the potential for settlement and deformation. Overall, geotextiles enhance the stability and longevity of railroad ballast, improving the performance of the track system.

- Q: Can geotextiles be used for reinforcement in landfills?

- Yes, geotextiles can be used for reinforcement in landfills. Geotextiles are commonly used as a geosynthetic material in landfill construction and operation. They are placed within the landfill to improve stability, prevent soil erosion, and enhance the overall strength of the landfill structure. Additionally, geotextiles help to control water flow and filter out contaminants, providing an effective solution for reinforcement in landfills.

- Q: How do geotextiles help with soil reinforcement in soft ground conditions?

- Geotextiles help with soil reinforcement in soft ground conditions by providing a stable and strong layer that distributes the load more evenly. They act as a barrier and prevent the intermixing of different soil layers, improving the overall stability and strength of the ground. Additionally, geotextiles can help with drainage by allowing water to pass through while retaining the soil particles, preventing erosion and maintaining the integrity of the ground.

- Q: What are the disadvantages of using geotextiles?

- There are several disadvantages of using geotextiles. Firstly, geotextiles can be quite expensive compared to other types of erosion control or soil stabilization methods. Additionally, they may require professional installation, which can add to the overall cost. Secondly, geotextiles are not a permanent solution and may degrade over time due to weather conditions and UV exposure. This can lead to the need for frequent replacements, resulting in additional expenses. Lastly, geotextiles may not be suitable for all soil types or project requirements, as they have limitations in terms of load-bearing capacity and effectiveness in certain applications.

- Q: Can geotextile be used as an insulation film?

- Yes, the company produces the country, the best quality geotextile materials, for example, long, short wire geotextile. Geotextile composite film. All kinds of grille, waterproof board and so on. Short wire geotextile prices, geotextile composite film specifications and other quality and cheap! The The Welcome to call to discuss, 0534-. Xujing Li.

- Q: Project, what is the use of permeable geotextile?

- In fact, geotextile has six main functions: 1. Isolation 2. Filter 3. Drain 4. Reinforcement 5. Protection 6. Closed. Can be applied to the four areas 1, water conservancy projects: seawall, embankment, lake embankment project; reservoir reinforcement project; reclamation project; flood control. 2, highway and railway airport engineering: soft foundation reinforcement; slope protection; road anti-reflective crack structure layer; drainage system; green isolation zone. 3, electrical engineering: nuclear power plant basic engineering; thermal ash dam project; hydropower project. 4, port waterway project: port. What you said is the drainage of water it. Is to rule out the excess water, to prevent soil erosion!

- Q: How do geotextiles enhance drainage systems?

- Geotextiles enhance drainage systems by providing filtration and separation of soil layers, preventing clogging and promoting water flow through the system.

Send your message to us

Geotextile Filter Fabric Construction Companies

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords