Composite Geotextiles for Architectural Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

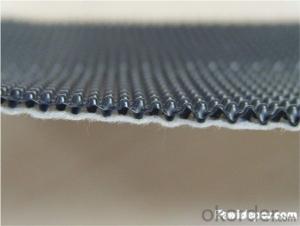

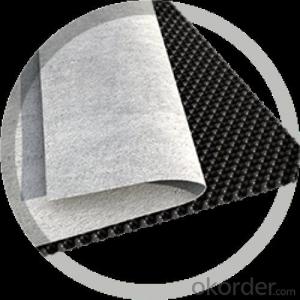

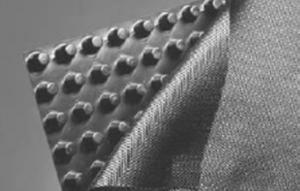

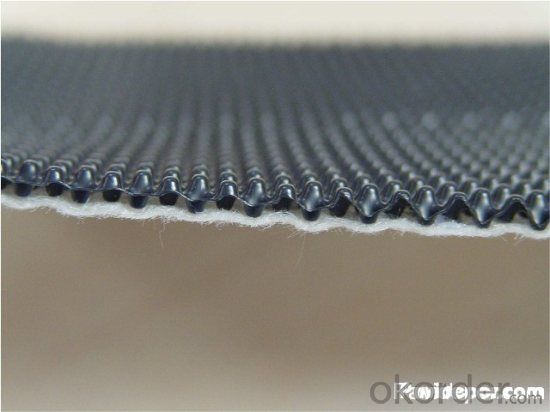

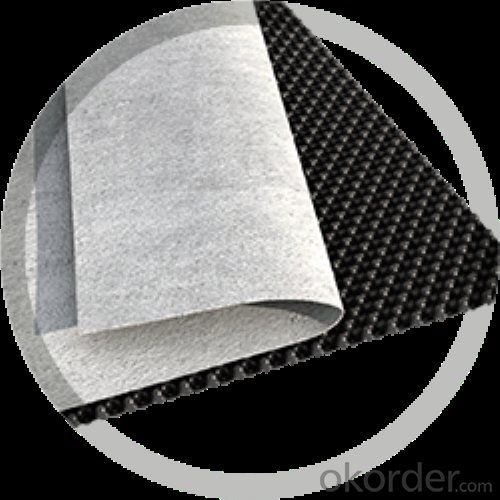

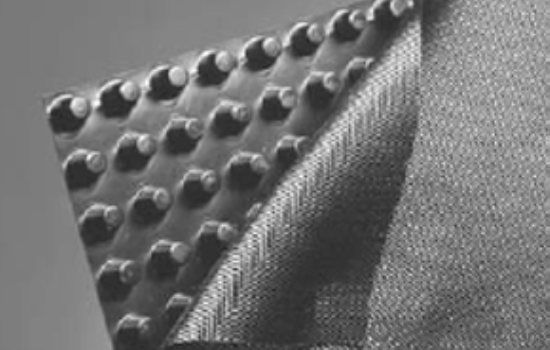

Composite Geotextiles for Architectural Engineering

Description Of Composite Geotextiles for Architectural Engineering

Composite material is a general term for the synthetic materials used in civil engineering. As a kind of civil engineering materials, it is to synthetic polymers, such as plastics, chemical fiber, synthetic rubber as raw material, made of various types of products, placed inside the soil, surface, or various kinds of soil play to strengthen or to protect the soil. The application of the technology of soil engineering synthetic materials will be divided into the type of the material of the soil, the soil, the soil, the special material and the composite. The special materials for the special materials include the soil engineering film bag, the soil engineering net, the geotechnical mesh pad, the soil working chamber, the soil texture, the bentonite mat, the polystyrene foamed plastics (EPS), etc.. The composite material is made from the above mentioned materials, such as composite coating, composite material, composite material, composite waterproof and drainage (drainage), etc..

Main Features of Composite Geotextiles for Architectural Engineering

The advantages of the composite is that the weight is light, and the overall continuity is good (can be made into a large area of the whole), construction is convenient, high tensile strength, corrosion resistance and resistance to microorganisms. The disadvantage is that, without special treatment, anti ultraviolet ability, such as exposure to ultraviolet radiation, is easy to aging, but if not directly exposed, the anti aging and durability performance is still high.

Applications of Composite Geotextiles for Architectural Engineering

1, for the stability of highway, railway roadbed.

2, used to bear the weight of the embankment and shallow water treatment.

3, used to prevent the landslide and the load of the gravity of the hybrid retaining wall.

IMages of Composite Geotextiles for Architectural Engineering

FAQ:

1. What are we supplying?

We are specialized in producing .geotextile , geocell, geogrid, geomembrane

2. How Many years experience do we have?

We have been exported to more than 15 countries in the past 10 years.

3. How long do we usually reply your request?

We always reply our customer within 12 hours.

- Q: What are the advantages of using precast concrete products?

- There are several advantages to using precast concrete products. Firstly, precast concrete is manufactured in a controlled environment, ensuring consistent quality and strength. This reduces the risk of variations in material properties that can occur with on-site concrete mixing. Secondly, precast concrete products can be produced in advance, allowing for faster construction processes and reducing project timelines. Additionally, precast concrete offers versatility in design, with various shapes, sizes, and finishes available, providing flexibility for architectural and structural requirements. Lastly, precast concrete products offer durability and low maintenance, as they are resistant to weathering, fire, and corrosion, making them a cost-effective choice in the long run.

- Q: What are the benefits of using geopipes in earthwork?

- The benefits of using geopipes in earthwork include improved drainage and groundwater management, increased stability and durability of the soil, and reduced erosion and sedimentation. Geopipes also enhance the overall efficiency of earthwork projects by accelerating the dewatering process and preventing soil contamination.

- Q: Are there any earthwork products specifically designed for golf course construction?

- Yes, there are earthwork products specifically designed for golf course construction. These products include specialized blends of soil, sand, and other materials that are formulated to meet the specific requirements of golf course construction, such as proper drainage, turf establishment, and playability. They are used to create the desired contours, slopes, and features of the golf course, ensuring optimal playing conditions.

- Q: Can earthwork products be used in greenway development?

- Yes, earthwork products can be used in greenway development. Earthwork products such as soil, rocks, and mulch can be utilized to reshape the land, create slopes, and build trails in greenway projects. These materials can help in creating natural and sustainable landscapes that blend seamlessly with the surrounding environment, allowing for the development of beautiful and functional greenways.

- Q: Are there any earthwork products specifically designed for oil and gas projects?

- Yes, there are earthwork products specifically designed for oil and gas projects. These products include geotextiles, geomembranes, geogrids, and erosion control materials. They are used to provide soil stabilization, prevent erosion, control sediment, and protect the environment during oil and gas exploration, drilling, and production activities.

- Q: How do earthwork products help with groundwater recharge?

- Earthwork products, such as retention ponds, infiltration basins, and bioswales, play a crucial role in groundwater recharge by effectively managing stormwater runoff. These products are designed to capture and slow down the flow of rainwater, allowing it to percolate into the ground and replenish the aquifers. Additionally, these structures also help filter out pollutants and sediments from the runoff, ensuring that the recharged groundwater is of good quality. Overall, earthwork products provide sustainable and efficient solutions to enhance groundwater recharge and maintain water balance in the ecosystem.

- Q: What are the cost implications of using earthwork products?

- The cost implications of using earthwork products can vary depending on factors such as the specific product used, the quantity required, and the project's scale and complexity. Generally, earthwork products like soil, gravel, and fill materials tend to be more cost-effective compared to other construction materials. They are often readily available and can be sourced locally, reducing transportation costs. Additionally, earthwork products can be recycled or repurposed, further reducing expenses. However, there may be additional costs involved in excavation, grading, and compaction processes to prepare the site for using these products. Overall, using earthwork products can offer cost advantages but should be carefully assessed in relation to the project's specific requirements.

- Q: What are the advantages of using geosynthetic liners in secondary containment systems?

- Geosynthetic liners offer several advantages in secondary containment systems. Firstly, they provide an impermeable barrier, preventing the leakage of hazardous substances into the environment. This helps in protecting soil and groundwater from contamination. Secondly, geosynthetic liners are highly flexible and can conform to different shapes and sizes, making them suitable for various containment applications. Additionally, these liners are resistant to chemical degradation, UV radiation, and mechanical stress, ensuring their long-term durability. Moreover, they are easy to install and require minimal maintenance, resulting in cost and time savings. Overall, geosynthetic liners enhance the effectiveness and reliability of secondary containment systems, promoting environmental safety and compliance.

- Q: How do geosynthetic clay liners prevent seepage in golf course ponds?

- Geosynthetic clay liners prevent seepage in golf course ponds by providing a barrier that effectively restricts the movement of water through the liner. The clay component of the liner swells upon contact with water, creating a low-permeability seal that prevents seepage. Additionally, the geotextile fabric on either side of the clay layer enhances the liner's durability and stability, ensuring long-term seepage control in the ponds.

- Q: How do earthwork products help with soil remediation?

- Earthwork products, such as geotextiles and geosynthetics, play a vital role in soil remediation processes. These materials are designed to enhance the performance and effectiveness of soil remediation techniques. Geotextiles provide reinforcement, filtration, and erosion control, while geosynthetics offer containment and barrier functions. When used in soil remediation, geotextiles can help stabilize and reinforce the soil, preventing erosion and soil loss during excavation and backfilling. They also act as a filtering layer, allowing water to pass through while retaining contaminants, preventing their spread to surrounding areas. Moreover, geotextiles can aid in the growth of vegetation, promoting the restoration of the remediated soil. Geosynthetics, on the other hand, are often used as liners or barriers in soil remediation projects. They help contain and isolate contaminants, preventing them from leaching into the groundwater or spreading to nearby soil. Geosynthetics also provide a protective layer, minimizing the exposure of underlying soil to harmful substances. Overall, earthwork products contribute to the success of soil remediation by improving the stability, filtration, containment, and barrier functions of the soil, ensuring a more efficient and sustainable remediation process.

Send your message to us

Composite Geotextiles for Architectural Engineering

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords