Geotextile Filter Fabric Membrane for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Geotextile Main Function:

*** Protection:

Geotextile can avoid the sharps objects damage to

pipeline and others buried underground.

*** Reinforcement:

Geotextile can reinforce the roadbed,

slow down the pavement fracture.

Other Application:

A. Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls.

At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

B. Separations:

The isolation of the railway dregs and the roadbed, roadbed and the soft base, different dam materials.

It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

C. Adding muscle:

The highway, railway of retaining wall, slope protection, etc in which distributes the earth stress,

prevents the side-displacement of the earth body and improves the earth body stability.

D. Protections

It prevents the bank from being washed out, protects the bank and the bottom,

prevents the water and soil from being washed away.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

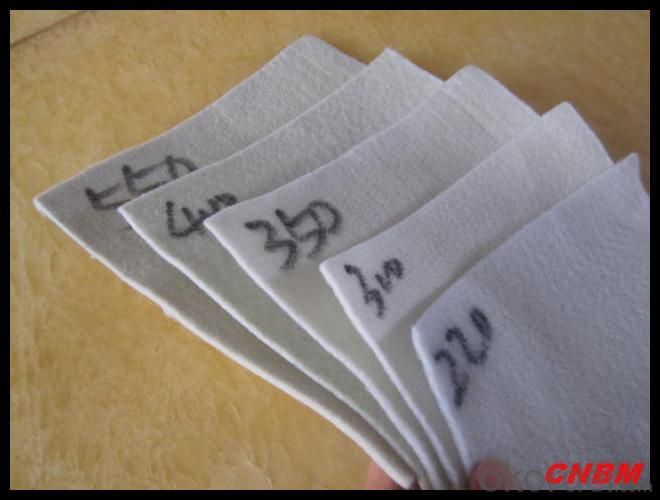

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are geotextiles resistant to acid degradation?

- Yes, geotextiles are generally resistant to acid degradation. They are designed to withstand various environmental conditions, including exposure to acids, making them suitable for applications where acid resistance is required.

- Q: How do geotextiles help in groundwater drainage?

- Geotextiles help in groundwater drainage by acting as a filter and separator between the soil and the water. They allow water to pass through while preventing the migration of fine particles, thus preventing clogging of drainage systems. Additionally, geotextiles help in distributing the flow of water evenly, reducing the chances of localized flooding and promoting efficient groundwater drainage.

- Q: How do geotextiles help with sediment retention in sediment basins?

- Geotextiles help with sediment retention in sediment basins by acting as a physical barrier that traps sediment particles while allowing water to pass through. They prevent erosion and sediment movement by stabilizing the soil, reducing the flow velocity of water, and promoting sediment settlement within the basin.

- Q: Geotextile back to the pebble and geotextile bag what inspection batch

- I professional production geomembrane geotextile and other materials, wish smooth

- Q: How are geotextiles recycled?

- Geotextiles can be recycled through a process called mechanical separation, where they are sorted, shredded, and then processed to remove any impurities. The shredded material is then transformed into new geotextile products or used as a raw material for other applications, reducing waste and promoting sustainability.

- Q: River design design depth of 1 meter, 100 meters wide surface, requiring geotextile cloth two films. How many grams are appropriate? Bao Bao package material per square meter open to move to cut the amount of taxation Bao Bao Bao how much money first thank you master, urgent use. More

- Collar - Xiang, composite geomembrane, geotextile, a variety of specifications

- Q: How do geotextiles contribute to the performance of geocell systems?

- Geotextiles play a crucial role in enhancing the performance of geocell systems. They are used as a lining material within the geocells, providing reinforcement and stability to the overall structure. Geotextiles help distribute loads evenly and prevent soil erosion, thereby increasing the strength and durability of the geocell system. Additionally, geotextiles promote effective filtration and drainage, allowing for proper water flow and preventing the accumulation of excess moisture within the geocells. Overall, geotextiles contribute significantly to the overall performance and longevity of geocell systems.

- Q: Can geotextiles be used in road shoulder stabilization?

- Yes, geotextiles can be used in road shoulder stabilization. Geotextiles are commonly used in civil engineering projects to reinforce and stabilize different areas, including road shoulders. They help to prevent erosion, improve soil stability, and provide a solid foundation for road construction.

Send your message to us

Geotextile Filter Fabric Membrane for Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords